Device and method for controlling radial temperature gradient of silicon carbide monocrystalline growth

A technology for controlling the temperature of silicon carbide and radial direction, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc. The effect of stable crystal growth rate, improved crystal quality and constant radial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

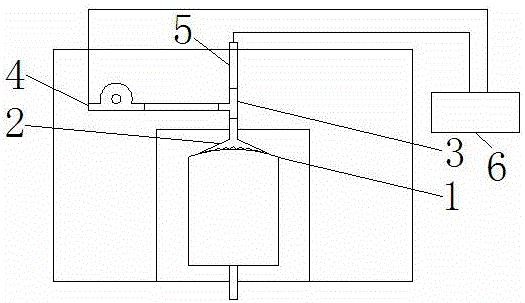

[0014] Such as figure 1 As shown, a device for controlling the radial temperature gradient of silicon carbide single crystal growth according to the present invention includes a carbon fiber conical blowing device 2 arranged above the crucible cover 1, and the upper port of the carbon fiber hammer blowing device 2 It is connected with the carbon fiber tee 3, one port of the carbon fiber tee 3 is connected with the frequency conversion circulating air device 4, the other port of the carbon fiber tee 3 is connected with the temperature measuring instrument 5, and the frequency conversion circulating air device 4 and the temperature measuring instrument 5 all link to each other with PLC control system 6.

[0015] A method for controlling the radial temperature gradient of silicon carbide single crystal growth, comprising the following steps,

[0016] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com