Preparation method of aluminum alloy tube busbar

A technology of aluminum alloy tubes and tube busbars, which is applied in the field of electric power, can solve problems such as potential safety hazards, and achieve good mechanical properties, reduce corona discharge, and good metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below through preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly.

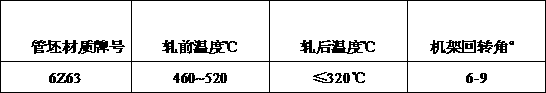

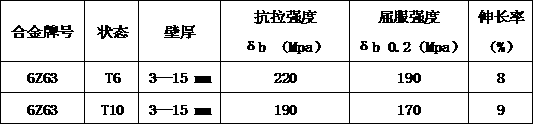

[0020] A kind of preparation method of aluminum alloy pipe bus bar of the present invention, prepare according to the following steps:

[0021] (1) Heat and melt 99.70% of the aluminum ingots for remelting in a heating furnace. The aluminum ingots for remelting must contain the following chemical components in weight percentages: Si: 0.20-0.60%; Fe: 0.30-0.40%; Cu: 0.10~0.20%; Mn: 0.08~0.12%; Mg: 0.45~0.70%; Cr: 0.08~0.12%; Zn: 0.08~0.12%; Re: 0.07~0.18%; Ti: 0.08~0.12%; ~0.20%, the balance is Al; heat up the furnace charge and fully melt it. During the heating process, remove the scum on the surface of the molten aluminum and stir it 2~3 times, each time for 2~3 minutes, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com