Receding aperture plate in cooling module of reflow welding stove

A cooling module and reflow furnace technology, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of increasing maintenance time and work difficulty, affecting the production efficiency and output of customers, and meeting the cooling efficiency and Temperature process curve requirements, improve operating time and production efficiency, save the effect of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

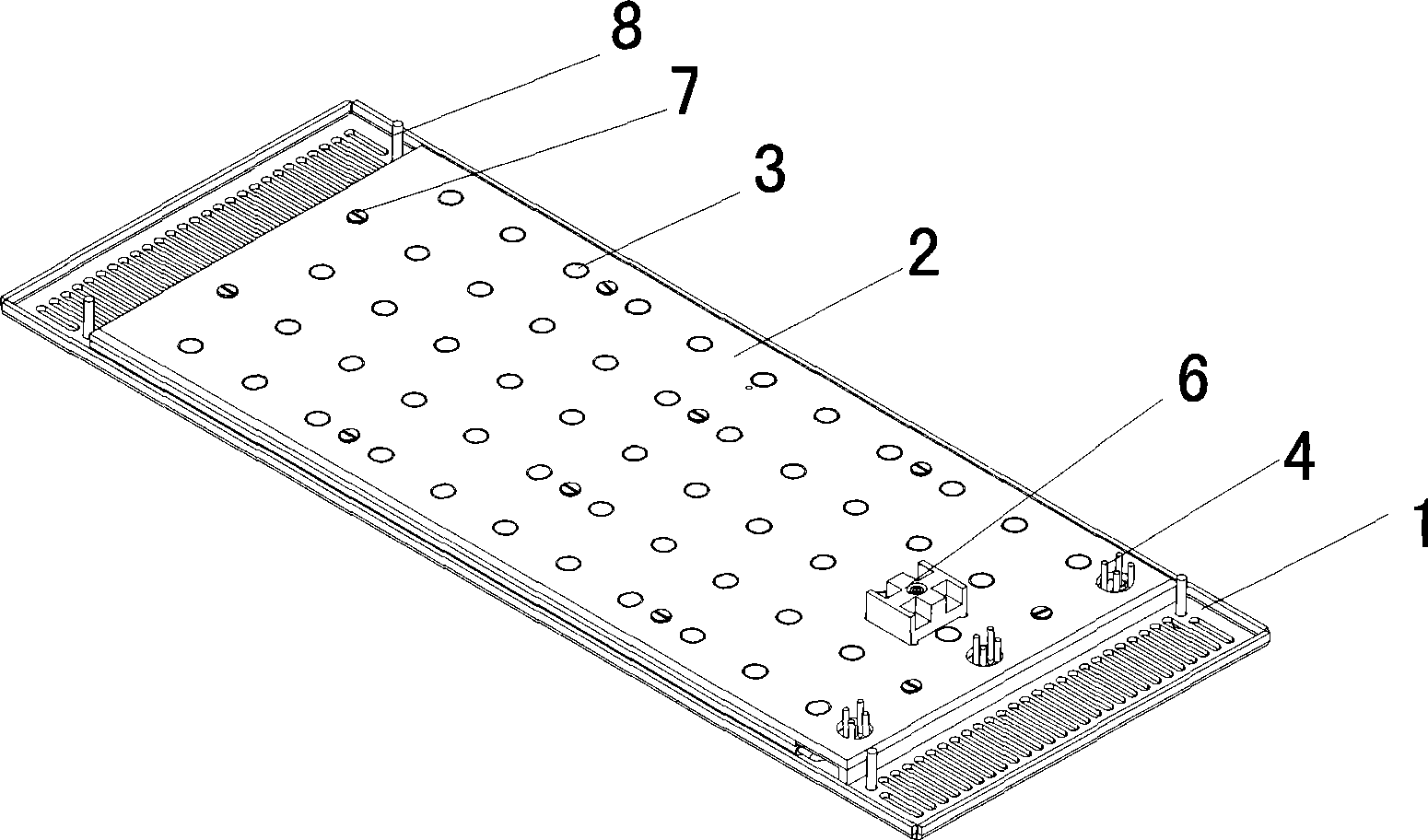

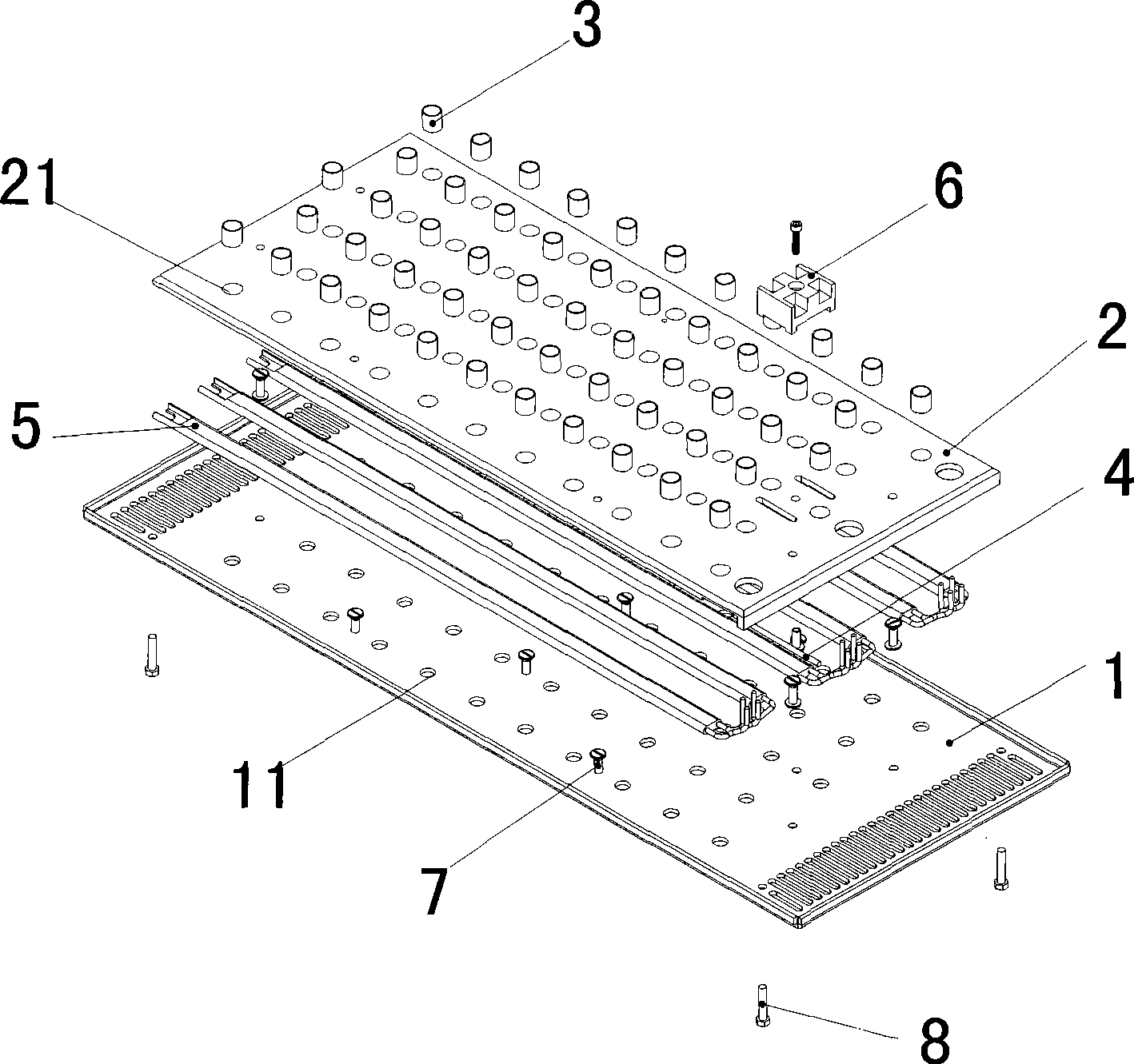

[0009] see figure 1 , figure 2 , the reflow orifice in the cooling module of the reflow oven of the present invention includes a reflow orifice body 1, a heat preservation plate 2, a plurality of Teflon air ducts 3, a temperature sensor 4, an electric heating wire 5 and ceramic terminals 6. A plurality of through holes 11, 21 for installing air guide pipes are correspondingly provided on the return orifice body 1 and the heat preservation plate 2, and a plurality of air guide pipes 3 are connected to the return orifice body 1 and the heat preservation plate 2, and the temperature sensor 4 And the electric heating wire 5 is respectively installed on the reflow orifice body and arranged between the reflow orifice body and the heat preservation plate, and the ceramic terminal 6 is installed on the upper surface of the heat preservation plate and is electrically connected with the temperature sensor. The return orifice body 1 and the heat preservation plate 2 are connected and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com