Road engineering material maintenance vehicle

A technology for road engineering and maintenance vehicles, which is applied in the direction of manufacturing tools, ceramic molding machines, and preparation of test samples. It can solve problems such as manual operation errors, humidity maintenance that cannot keep up, and test pieces that cannot be accurately controlled. achieve an easy-to-move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

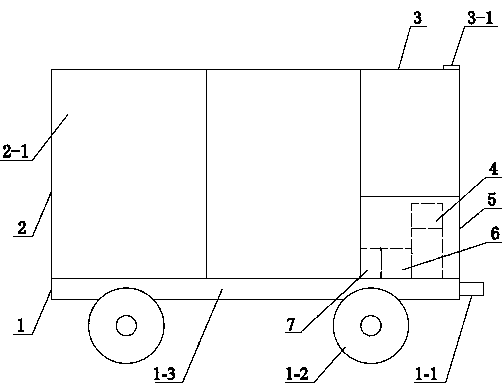

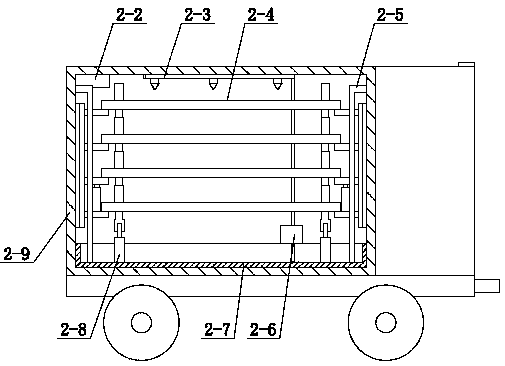

[0020] Such as figure 1 with figure 2 The shown road engineering material maintenance vehicle includes a trailer chassis 1, a maintenance box 2, a water tank 3 and an equipment box 5, and the trailer chassis 1 includes a vehicle frame 1-3, wheels 1-2 and The traction frame 1-1 that is arranged on the front side of the vehicle frame. The curing box 2 and the water tank 3 are arranged side by side on the trailer chassis 1, and the equipment box 5 is arranged at the lower front corner of the water tank 3, that is, the water tank 3 and the equipment box 5 form a square box. The curing box 2 comprises a square box body 2-9 with an open side and two side-opening box doors 2-1 arranged outside the opening of the box body 2-9. The curing box 2 is a sealed heat preservation box, the water tank 3 is a closed water tank, and the top of the water tank 3 is provided with a water injection port with a water injection plug 3-1.

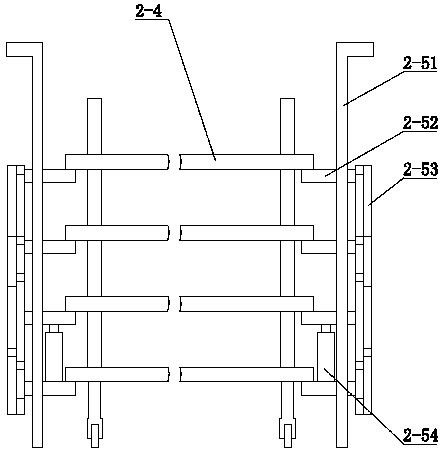

[0021] As shown in Figure 2, the curing box 2 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com