Temperature detection device of polishing interface and utilization of temperature signals in chemically mechanical polishing process

A temperature detection device, chemical mechanical technology, applied in the direction of measuring devices, thermometers and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of high equipment cost and low precision, and achieve low cost and stability High, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. Specific details are set forth in the following description to facilitate a full understanding of the present invention, but the present invention can be implemented in many other ways than described herein, so the present invention is not limited by the specific embodiments disclosed below.

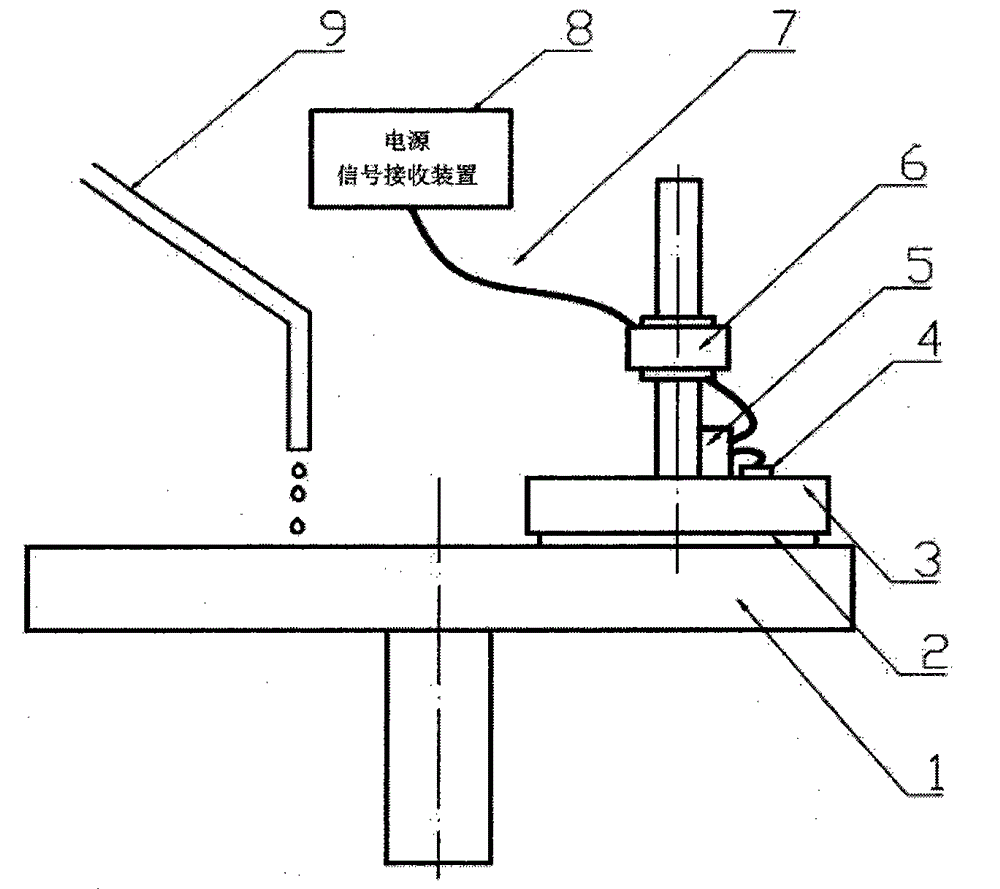

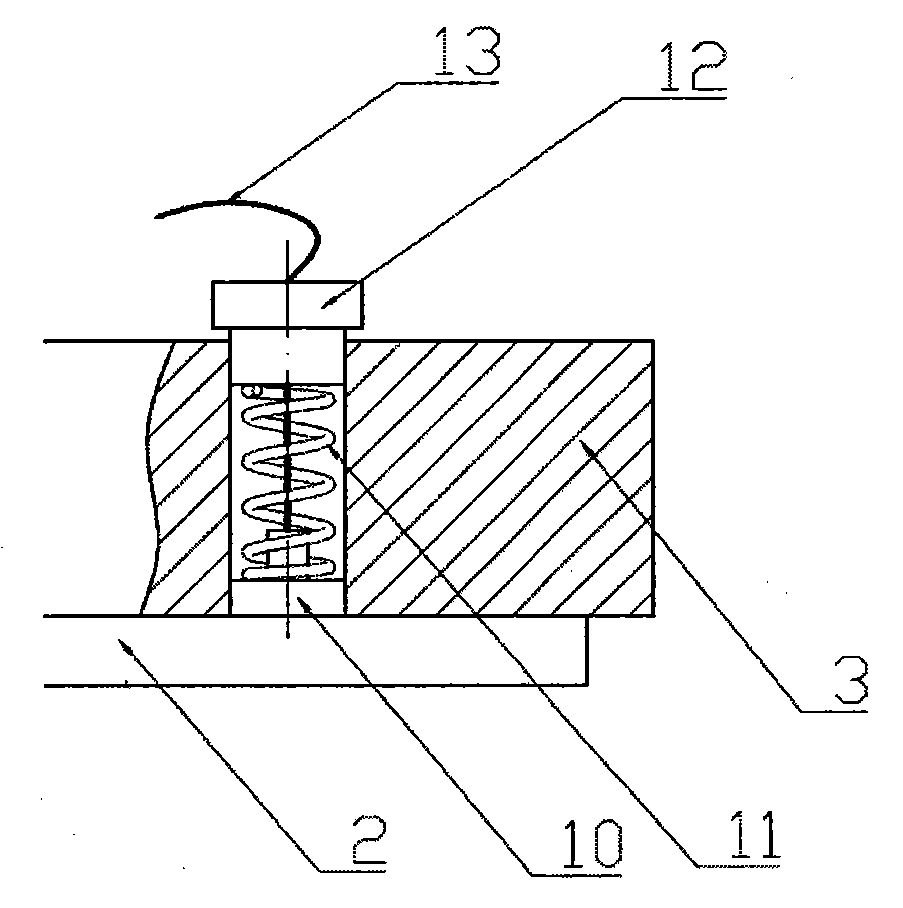

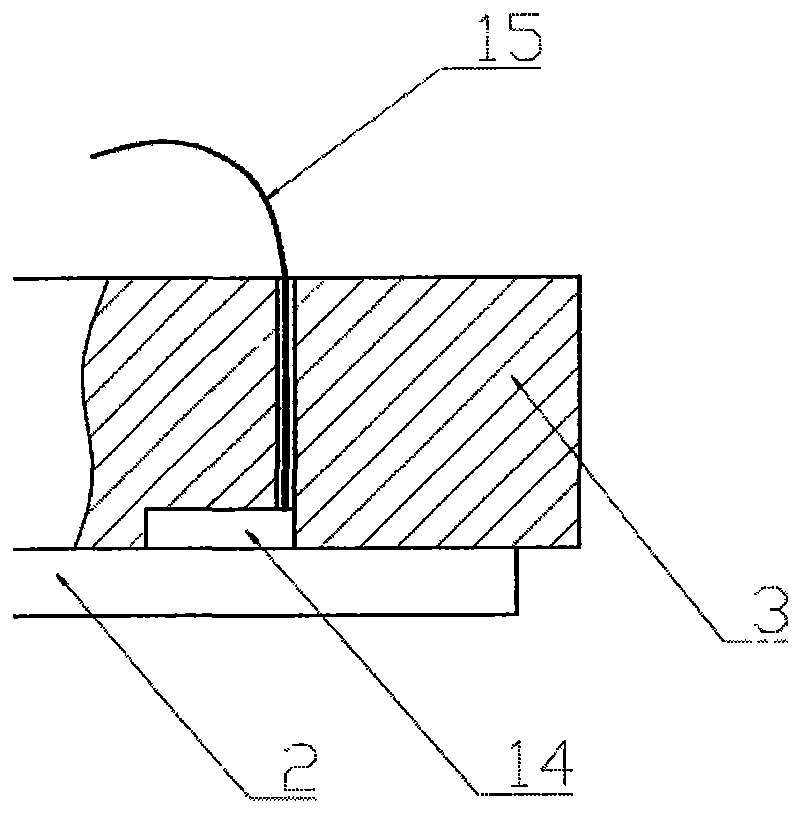

[0038] An embodiment of the polishing interface temperature detection device provided by the patent of the present invention is as follows: figure 1 As shown, the device is composed of a temperature sensor 4, a signal processing module 5, a conductive slip ring 6, a power supply and a signal receiving device 8, and a wire 7 connecting various components. exist figure 1 Among them, the clamper 3 clamps the workpiece 2 to be polished and presses it on the polishing disc and the polishing pad 1, the polishing disc and the polishing pad 1, and the clamper 3 rotate around their axes re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com