Seasoner sponging drying machine group

A drying unit and seasoning technology, applied in dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of increasing pollution, reducing heat energy effect, complex process structure, etc., to improve drying efficiency and prevent sticking. The effect of wall phenomenon and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

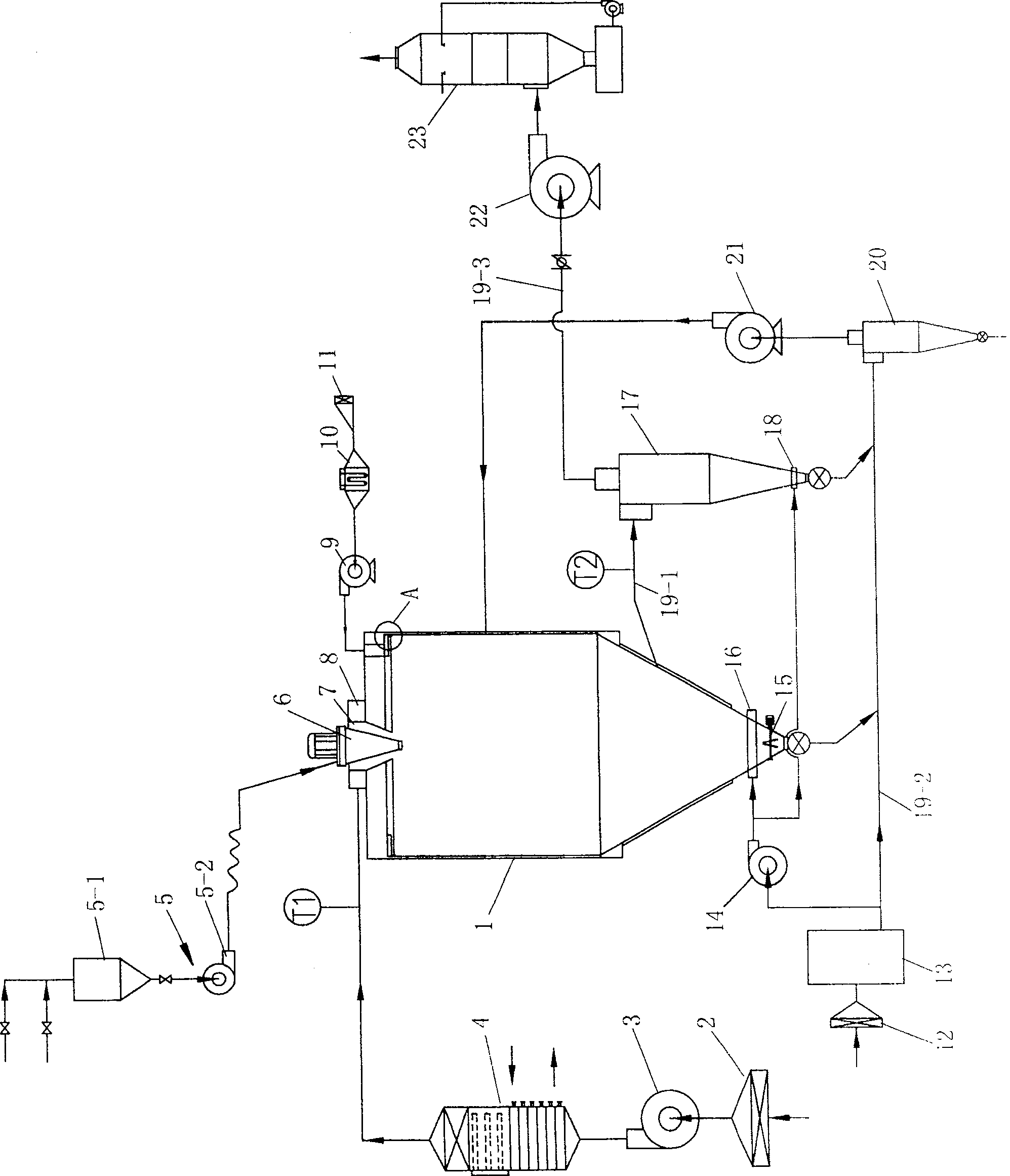

[0032] See figure 1 , the present invention includes feeding device 5, drying tower 1, No. 1 fan 3, No. 1 heater 4, primary cyclone separator 17 and water film deduster 23. The feeding device 5 includes a hopper 5-1 and a feeding pump 5-2, and the feeding pump is a peristaltic pump.

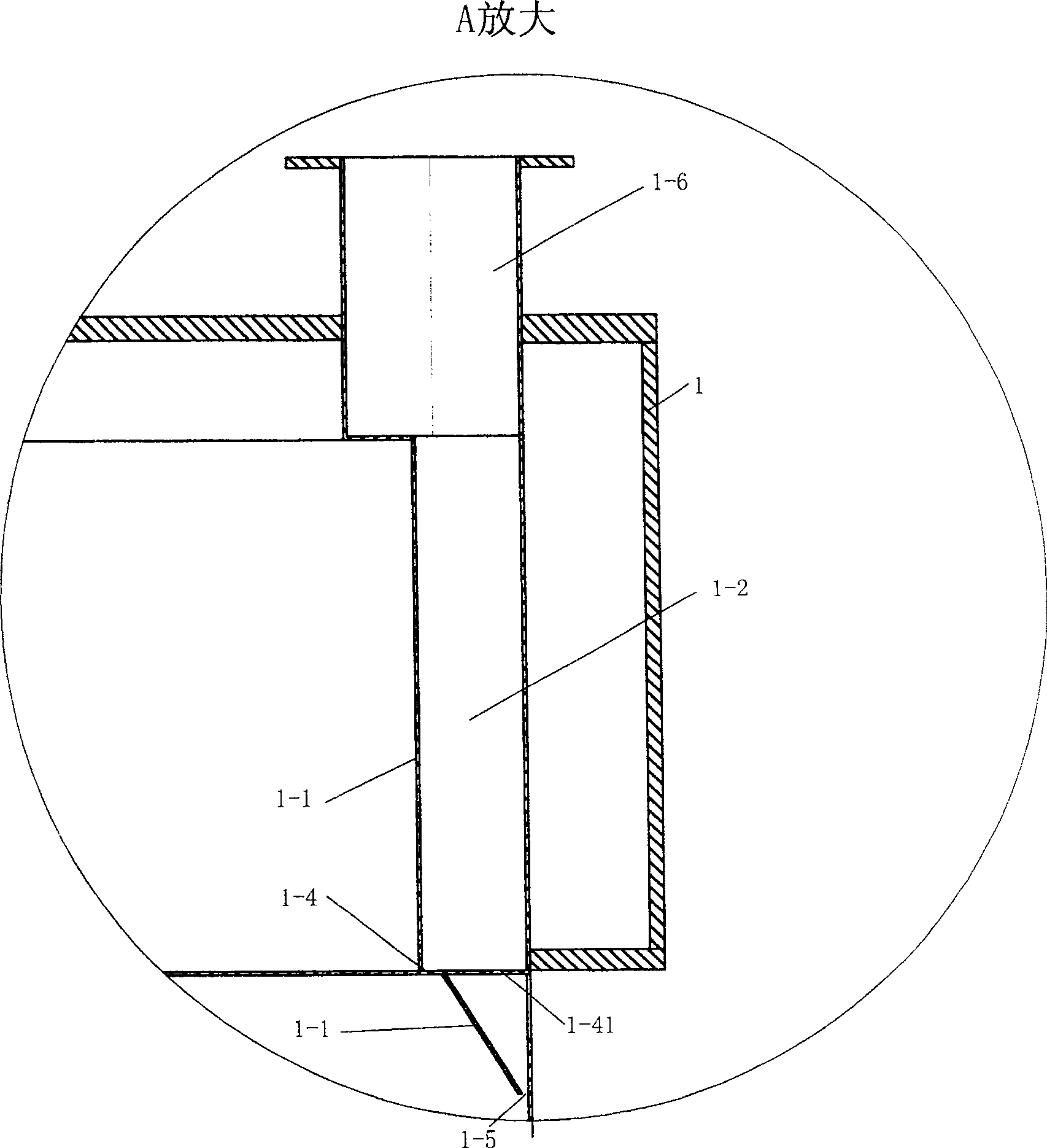

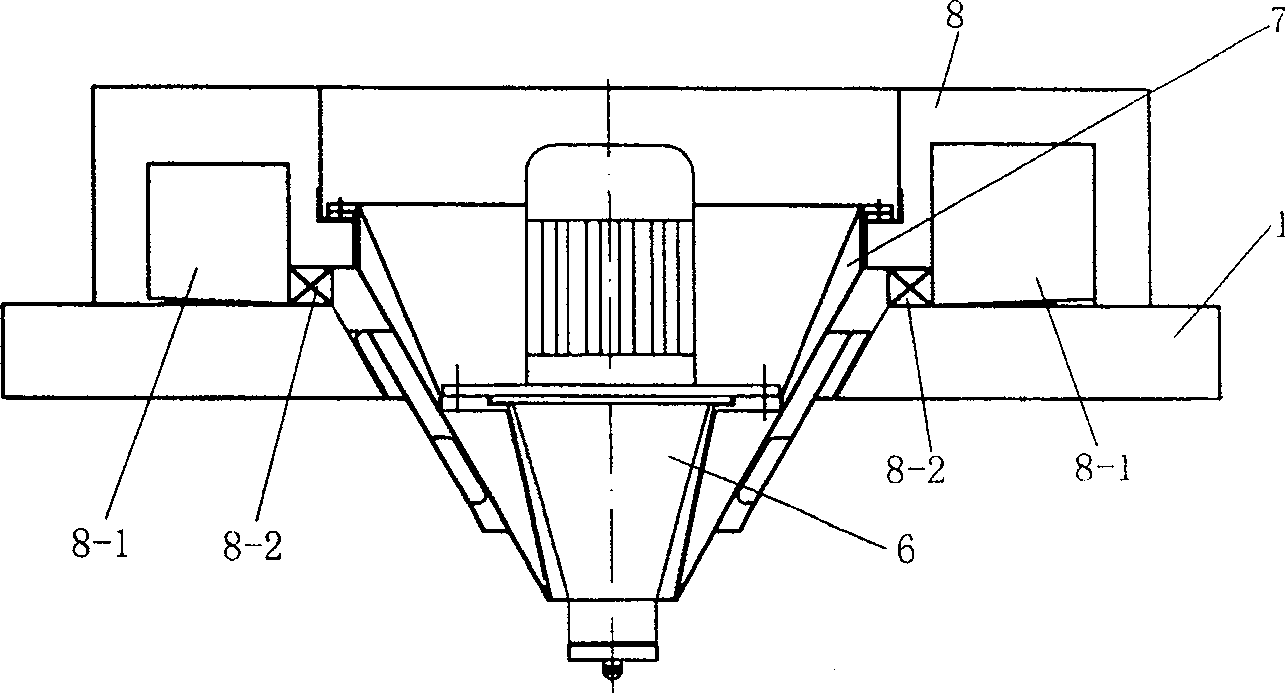

[0033] See figure 1 , 3 and 4, the central hot air inlet at the top of the drying tower 1 is provided with a hot air distributor 7 and an atomizer 6 installed in the center of the hot air distributor and connected to the feeding device 5 . The top of the drying tower 1 is provided with an air channel plate 8 with a volute-shaped air channel 8-1, the inlet of the air channel plate 8 is connected to the output pipeline of No. 1 heater 4, and the outlet of the air channel plate 8 is connected to the hot air distributor. 7 import connections. The volute-shaped air channel 8-1 of the air channel plate 8 has a square cross-section, its cross-section gradually shrinks and the bottom surface is incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com