Polymerization kettle for producing suspension polytetrafluoroethylene

A polytetrafluoroethylene and polymerization kettle technology, applied in the field of polymerization kettles, can solve problems such as dead corners, low production efficiency, and potential safety hazards, and achieve the effects of reducing sticking to walls and being easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

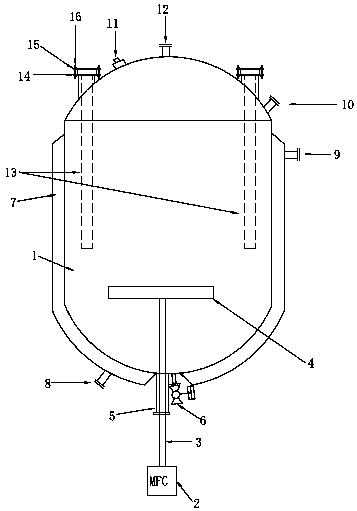

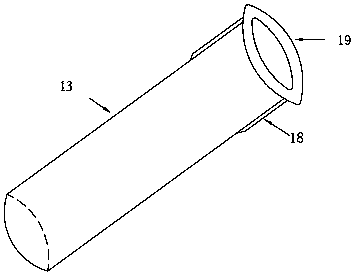

[0014] Refer to attached Figure 1-2 , a polymerization kettle for the production of suspended polytetrafluoroethylene, the lower part of the kettle body 1 is equipped with an agitator shaft 3, the top of the agitator shaft 3 is equipped with a stirring paddle 4, and the place between the agitator shaft 3 and the kettle body 1 Organic sealing system 5, driven by motor system 2 installed at the bottom, feeding ball valve 6 installed at the bottom of kettle body 1, reaction kettle jacket 7 outside the kettle wall, upper refrigerant inlet 8, lower refrigerant outlet 9, above-mentioned upper refrigerant inlet 8, The lower refrigerant outlet 9 can take away the energy released during the reaction in time; the upper head of the kettle body 1 has a material inlet 10, a hand hole 11, and a manhole 12; the baffle 13 is suspended from the upper head of the kettle body 1 and inserted into the kettle. The flange 19 is placed between the flange 14 and the flange gland 15, and is fixed by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com