Drying machine based on mineral drying agent form

A desiccant and dryer technology, applied in the direction of dryers, drying solid materials, drying chambers/containers, etc., can solve the problems of inconvenient replacement of desiccants, uncontrollable humidity, large space occupation, etc., and achieve more humanized operation , realize the effect of intelligent precision control humidity, easy installation and configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

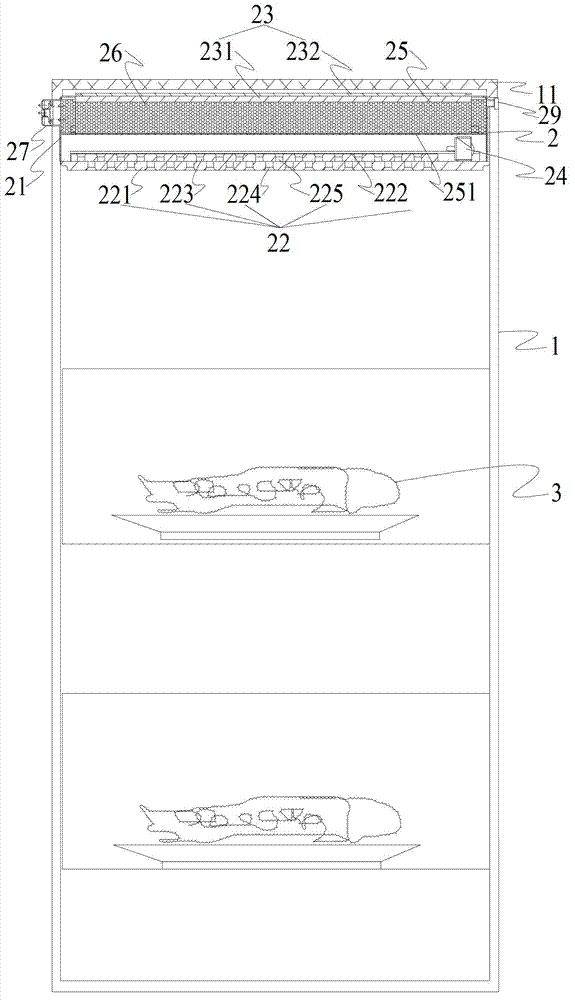

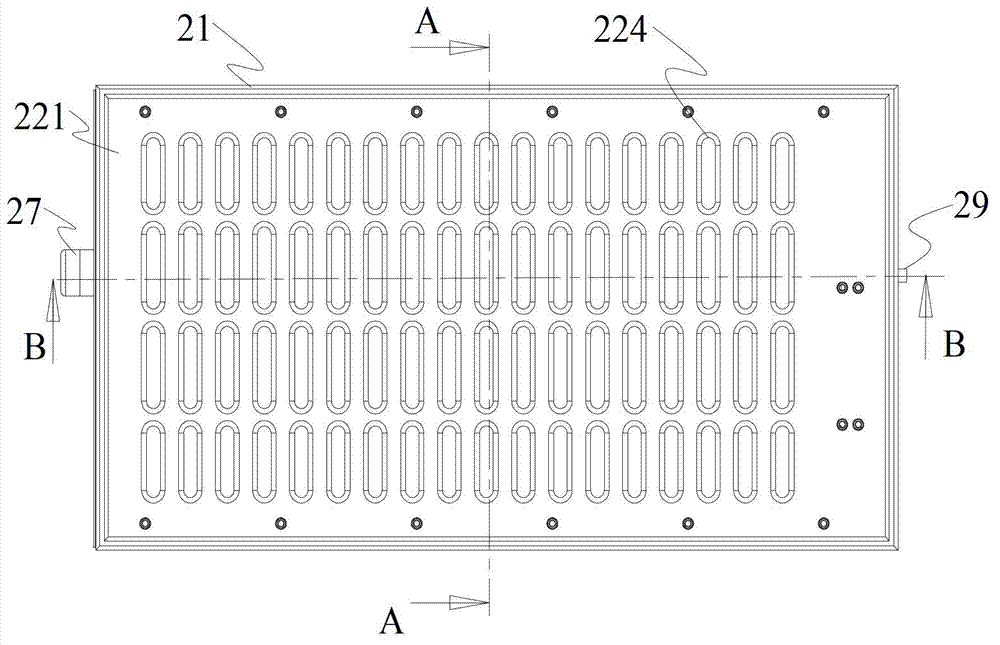

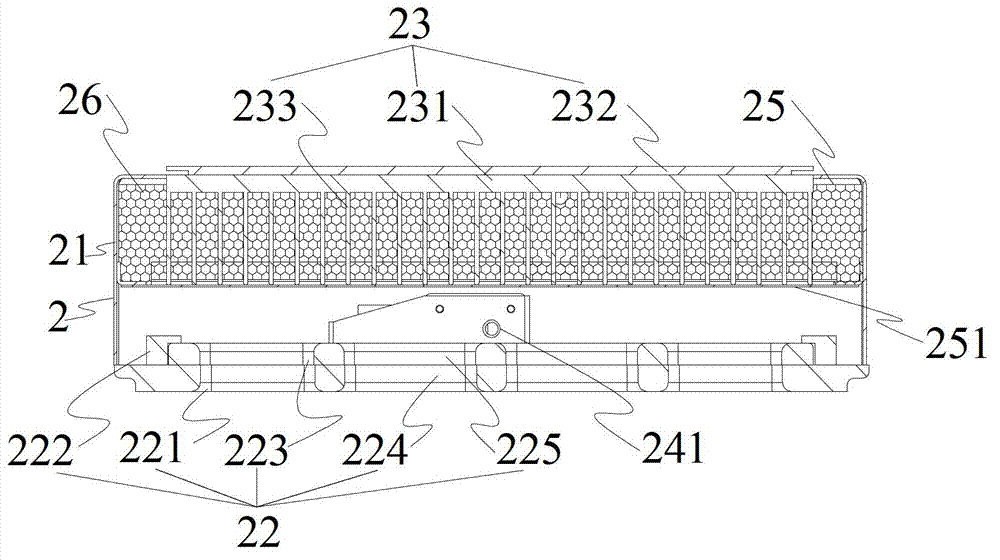

[0036] Such as Figure 1 to Figure 5 As shown, embodiment one is based on a mineral desiccant dryer, including a container 1 (such as a cabinet, a bottle, etc.) for accommodating the object to be dried 3 and having a container door (not shown), A container humidity sensor (not shown), a container door status sensor (not shown) for sensing container door opening or closing, a micro control unit MCU (not shown) and a drying device 2 on the top of the container The drying device 2 includes a sealed box body 21, a moisture absorption door 22 located at the bottom of the box body, a driving device (ie, a motor 24 or other power devices, such as electromagnetic power, etc.) that drives the moisture absorption door 22 to open or close, for A hygroscopic door status sensor (not shown) for sensing the opening or closing of the moisture-absorbing door 22, a heating unit 23 arranged on the top of the box body, a temperature sensor (not shown) arranged on the heating unit, and a temperatu...

Embodiment 2

[0045] Such as Figure 6 to Figure 10 As shown, Embodiment 2 is based on a dryer of mineral desiccant type. The cross section of the container 1 is a circular structure, and the drying device 2 is a circular drying device; The moving piece 223 is driven to rotate around the central axis 28, so that the hole 224 of the fixed piece and the hole 225 of the moving piece are aligned or staggered; other structures of the second embodiment are the same as those of the first embodiment.

[0046] In the second embodiment, the moving piece 223 is sleeved on the central shaft 28, and the moving piece holder 222 may not be needed; the central shaft 28 is connected to the motor 24, so that the motor 24 drives the moving piece 223 to rotate around the central shaft 28; When the moving piece 223 turns to the holes of the moving piece hole 225 and the fixed piece hole 224 to overlap to form an airflow passage; Its airflow path is disconnected. The moving plate holes 225 are arranged in a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com