Liquefied natural gas bottle sandwiching vacuum-pumping system and method with function of circularly heating inner container

A technology of liquefied natural gas and vacuum system, which is applied in the field of vacuum system, can solve the problems of high cost, high use cost, and large energy consumption, and achieve the effects of reduced use cost, reduced manufacturing cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

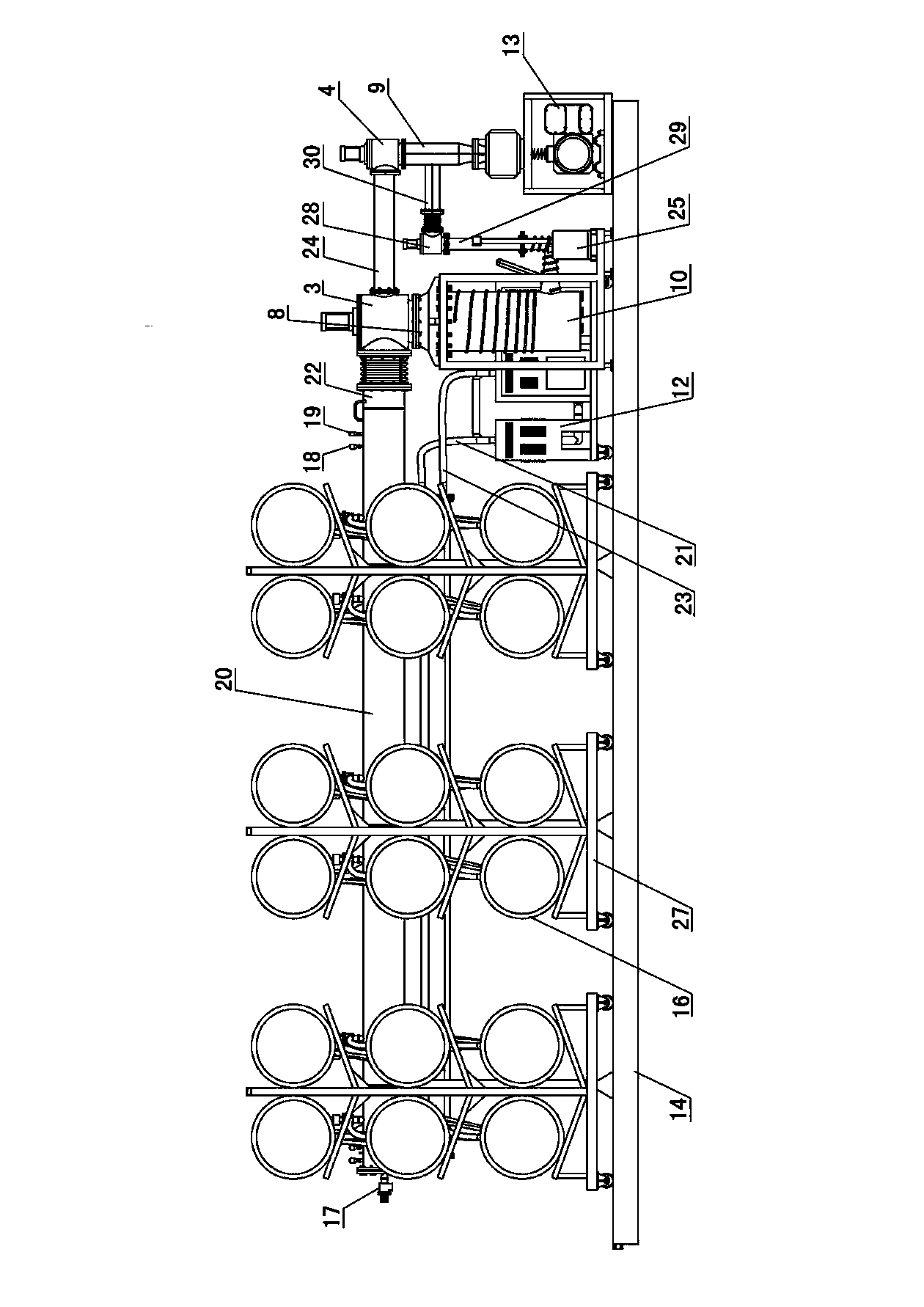

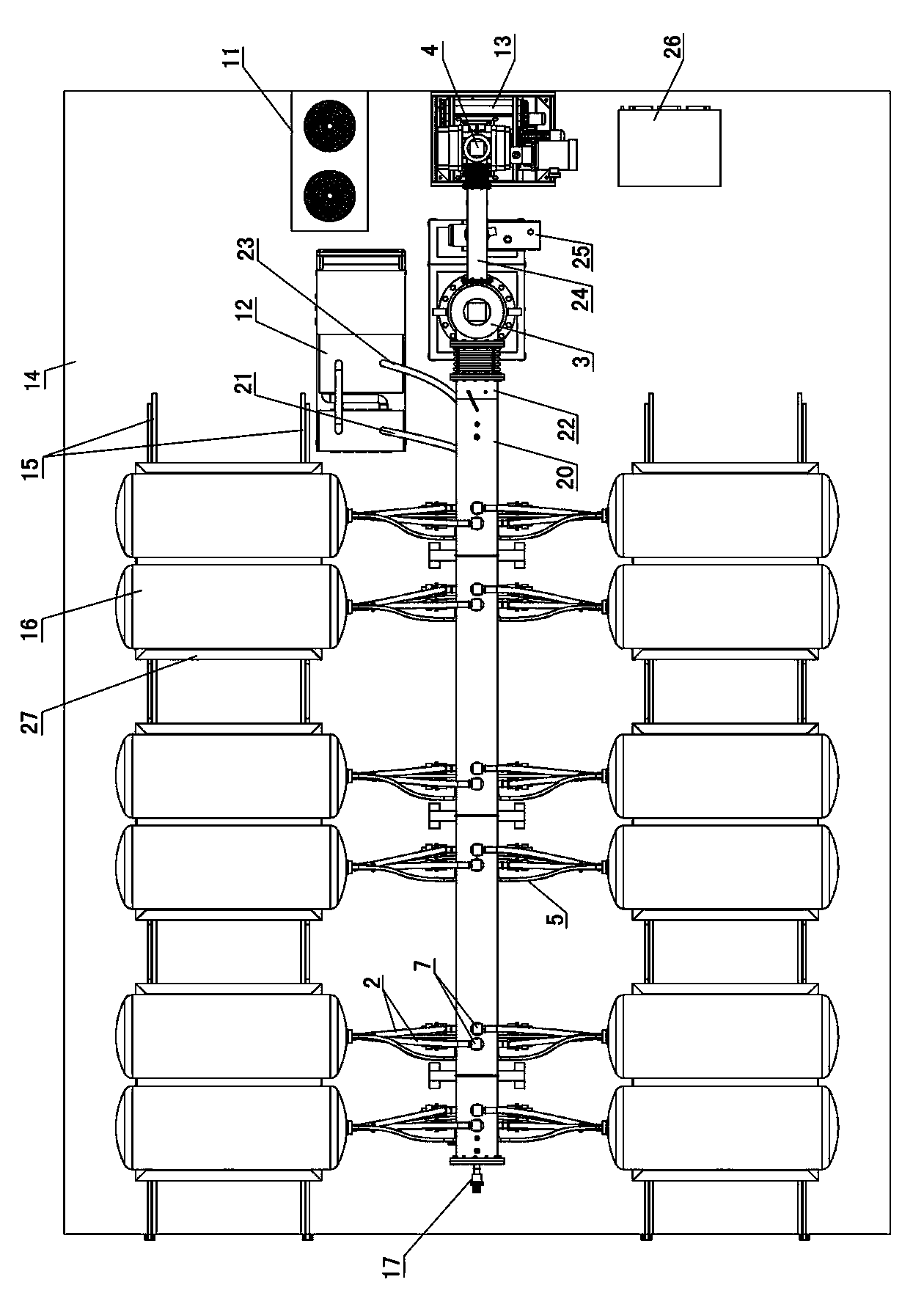

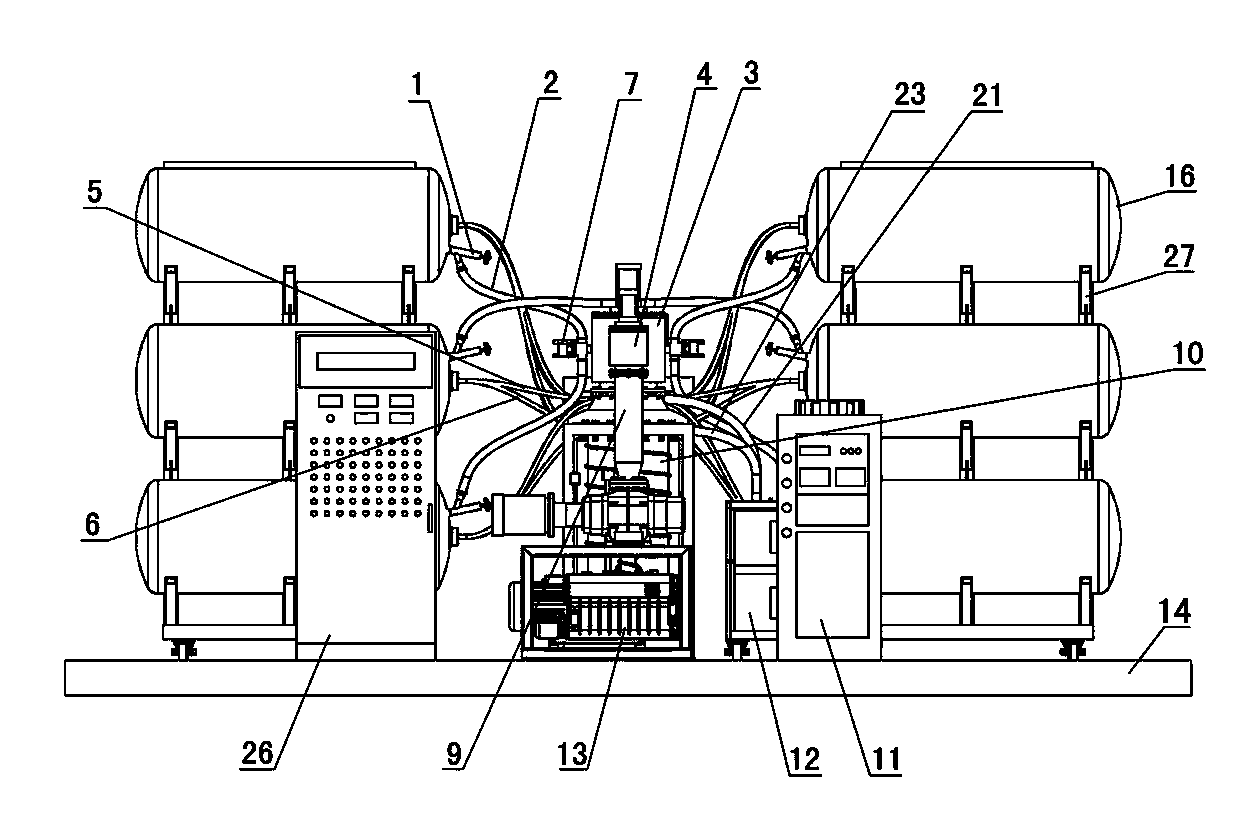

[0039] Examples see Figure 1-3 As shown, the interlayer vacuum pumping system for liquefied natural gas cylinders with liner circulation heating includes a vacuum pumping device, a liquefied natural gas bottle placement device and a heating device inside the liquefied natural gas bottle, and also includes a control device for controlling the operation of the entire vacuum pumping system. Cabinet 26.

[0040] The internal heating device of the liquefied natural gas cylinder includes a dry oil-free internal heating circulating fan 12, a heat inlet main pipe 21, a heat exhaust main pipe 23, a heat inlet branch pipe 5 and a heat exhaust branch pipe 6, wherein the dry oil-free internal heating circulation fan 12 The output pressure is above 70kpa, and the temperature resistance is above 350 degrees. The air outlet of the dry oil-free internal heating circulation fan 12 is connected to the heat inlet main pipe 21, and the heat inlet pipe 21 is connected to the heat inlet branch pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com