Dismantling equipment and dismantling process for scrapped automobiles

A technology for scrapping cars and equipment, applied in welding equipment, vehicle scrap recycling, metal processing equipment, etc., can solve problems such as excessive smoke, harm to workers' health, and unorganized emission of smoke and dust, so as to ensure the effect of vacuuming and protect the body of workers. Health, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

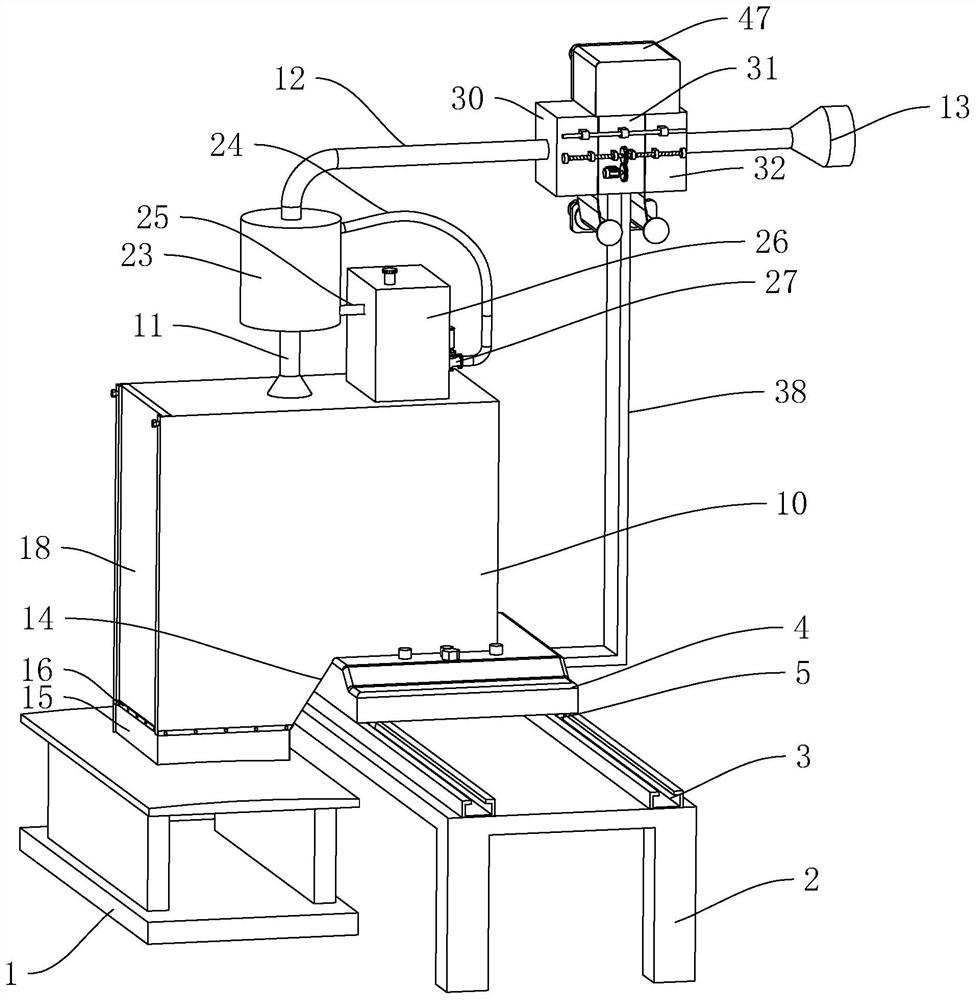

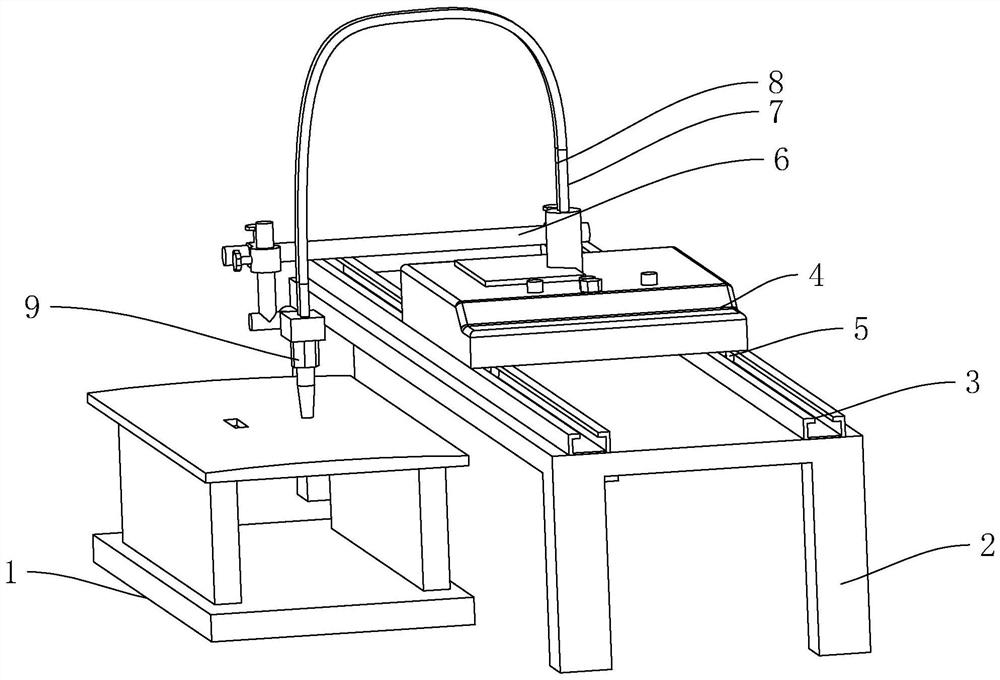

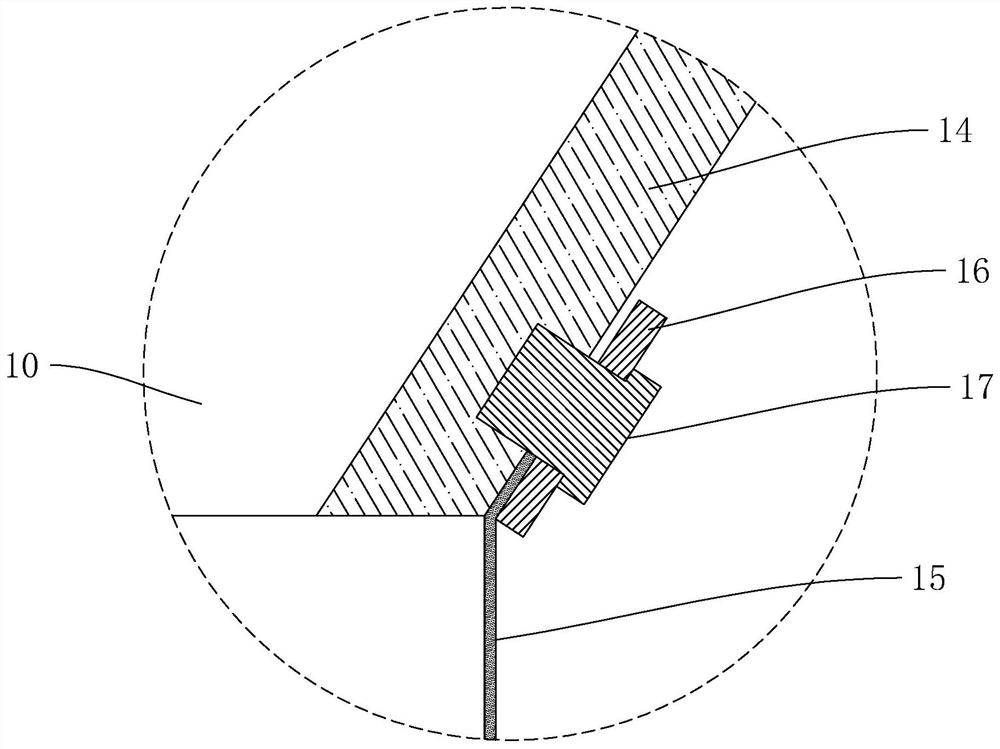

[0047] Embodiment one: refer to figure 1 with figure 2 , is a scrapped automobile dismantling equipment disclosed by the present invention, comprising a workbench 1 arranged horizontally, a support 2 is arranged on one side of the workbench 1, a rectangular slide rail 3 is welded on the top of the support 2, and a The slider 4, the slider 4 rotates towards the side of the slide rail 3 and is connected with the travel wheel 5 rollingly connected with the slide rail 3, the slider 4 is provided with a drive mechanism for driving the travel wheel 5, and the drive mechanism is a travel motor and a reduction box , the rotating shaft of the walking motor is fixedly connected to the input shaft of the reduction box, the output shaft of the reduction box is fixedly connected to the traveling wheel 5, and an adjustment rod 6 connected to the slider 4 is arranged above the workbench 1, and the adjustment rod 6 faces one end of the slider 4 Welded with the slider 4, the end of the adjus...

Embodiment 2

[0058] Embodiment two: a kind of scrapped automobile dismantling process, comprises the following steps:

[0059] Inspection and registration, inspection and registration of scrapped car information;

[0060] Pretreatment, removal of batteries, removal and detonation of airbags, removal of waste capacitors and exhaust gas purification catalysts containing PCBs, emptying and collection of waste liquids in cars, and recycling of automotive air-conditioning refrigerants;

[0061] Dismantling, using the scrapped car dismantling equipment as described in Example 1 to cut and disassemble the car body, and then remove the fuel tank, oil filter, glass, parts containing toxic substances, converter and muffler, tires, copper Aluminum parts, plastic parts, rubber parts, assemblies and parts;

[0062] Storage and management, classified storage and labeling of disassembled parts, materials and waste.

[0063] The implementation principle of Embodiment 1 and Embodiment 2 is: when the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com