Self-cleaning observation window device

An observation window and self-cleaning technology, applied to cleaning methods and utensils, cleaning methods using tools, furnaces, etc., can solve problems that affect the temperature in the furnace and cannot be used, and achieve the effect of ensuring the observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

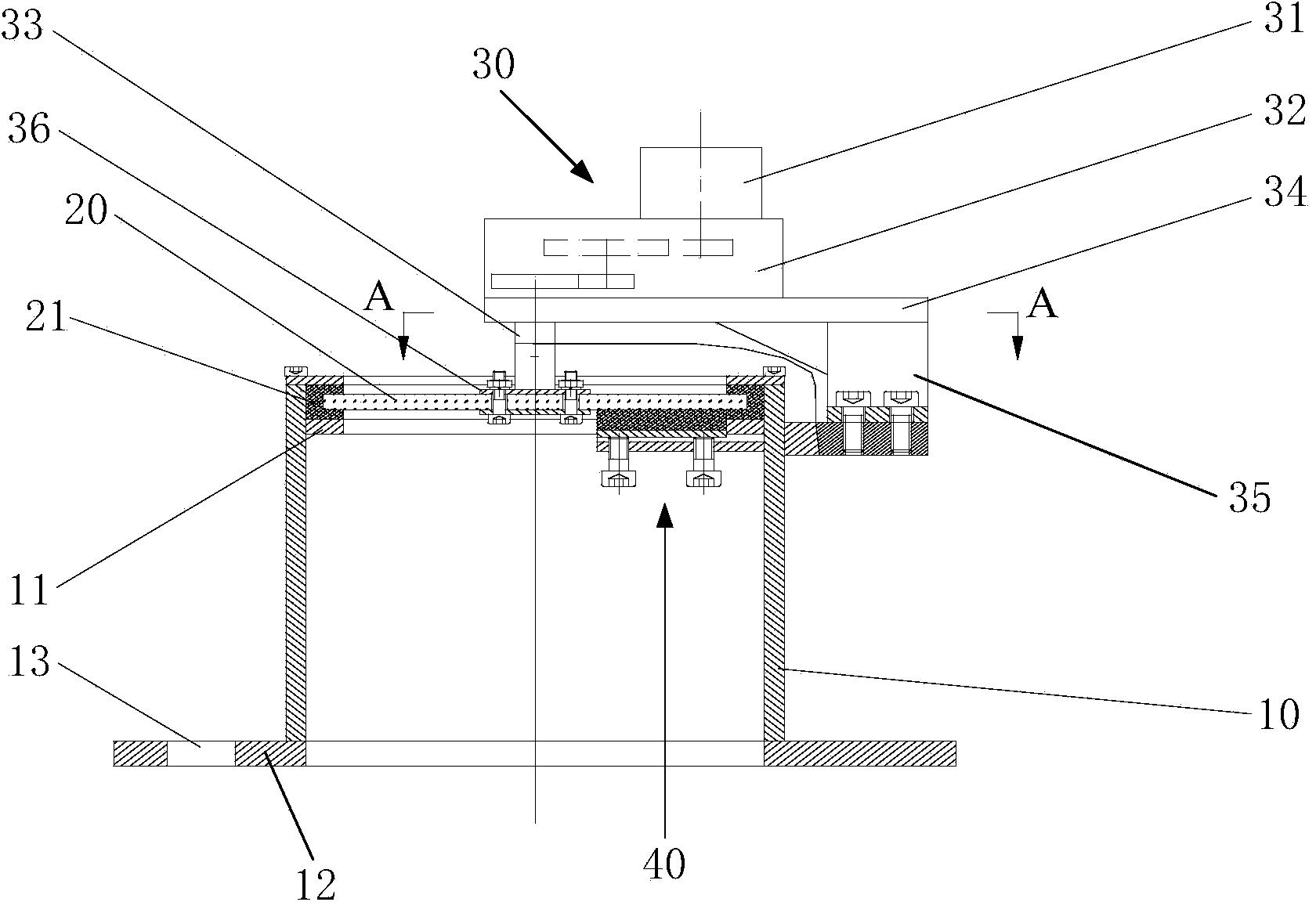

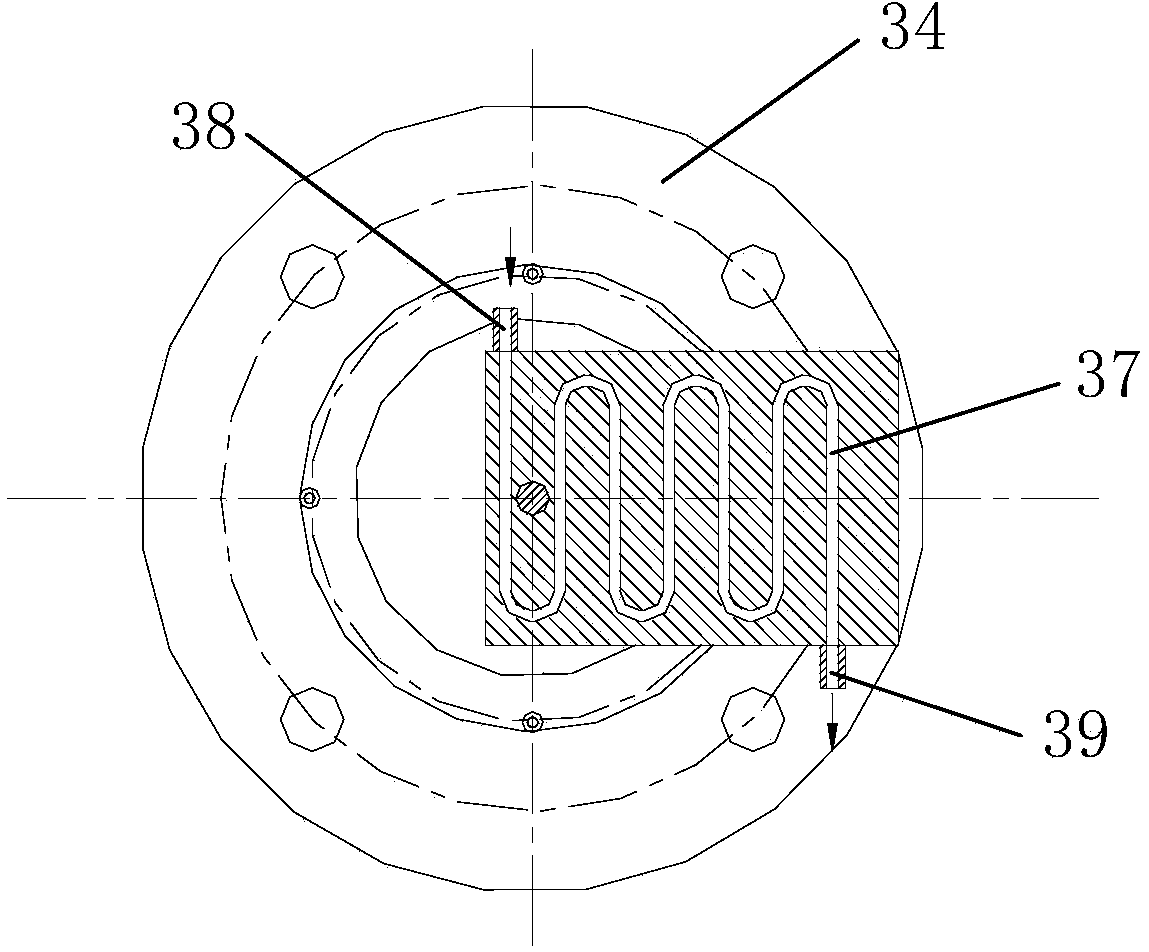

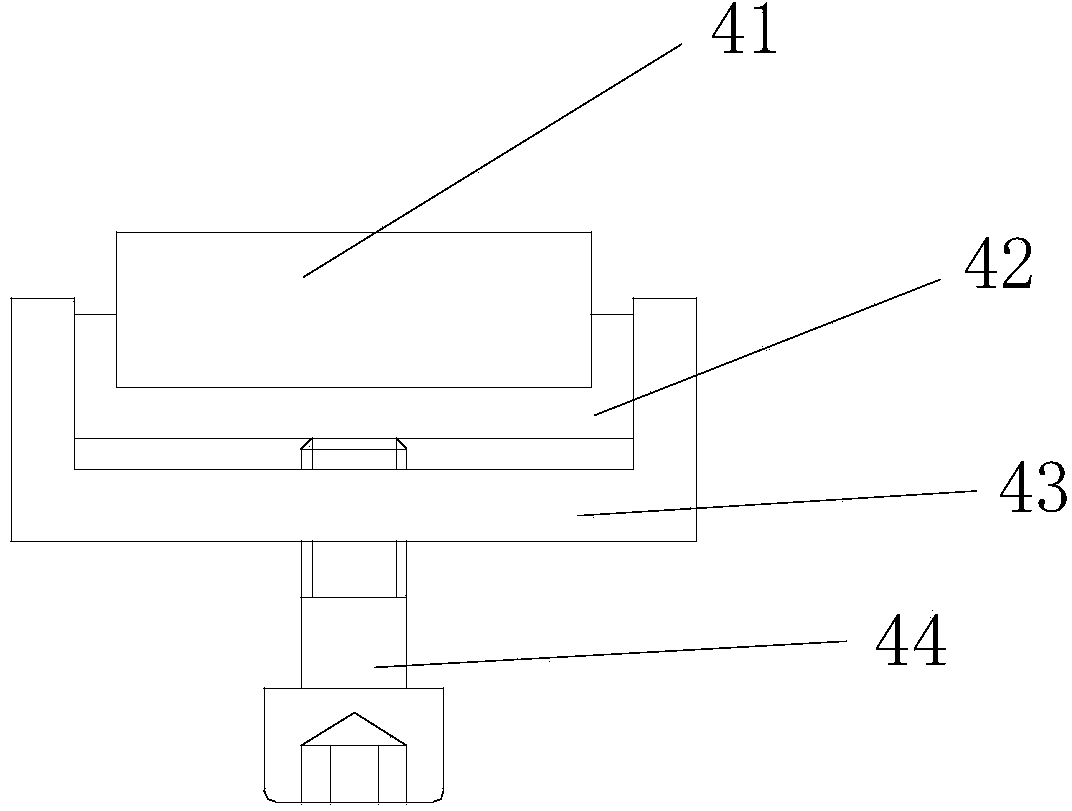

[0027] Self-cleaning observation window device provided by the present invention, such as figure 1 As shown, it includes a housing 10 with openings at both ends, an observation window glass 20, a rotary drive mechanism 30 and a cleaning brush mechanism 40, wherein,

[0028] One end opening of the housing 10 is fixed to the object to be observed, specifically, the bottom of the housing 10 is provided with a housing base 12, and the housing base 12 is provided with a fixed connection with the object to be observed. A fixing hole 13, through which the casing 10 is fixedly connected with the object to be observed; the observation window glass 20 is installed at the opening at the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com