Pneumatic precision micropump

A pneumatic drive, micro-pump technology, used in laboratory utensils, laboratory containers, fluid controllers, etc., can solve problems such as inability to achieve precise fluid control, lack of fluid drive, etc., and achieve precise drive and precise flow adjustment. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

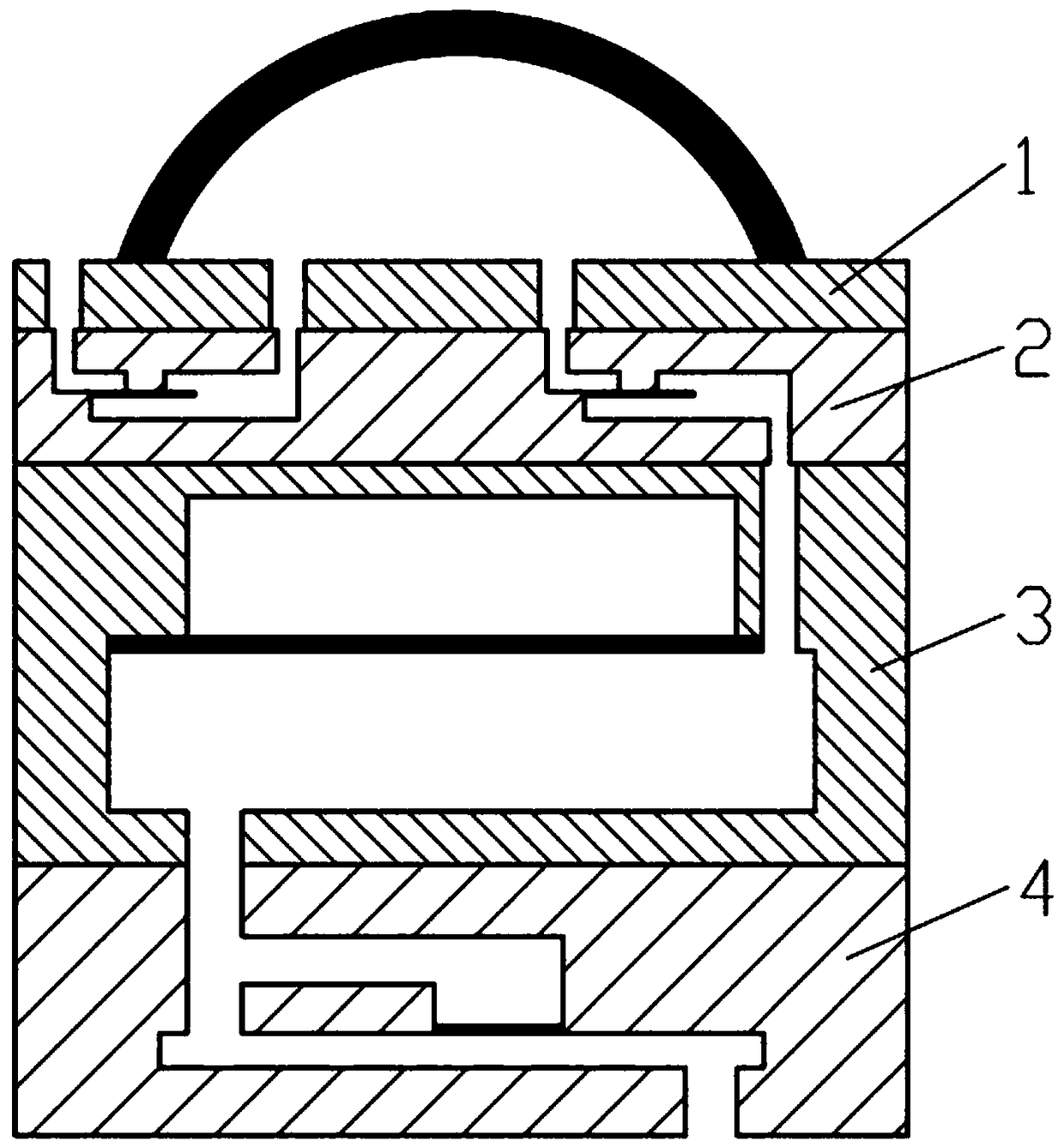

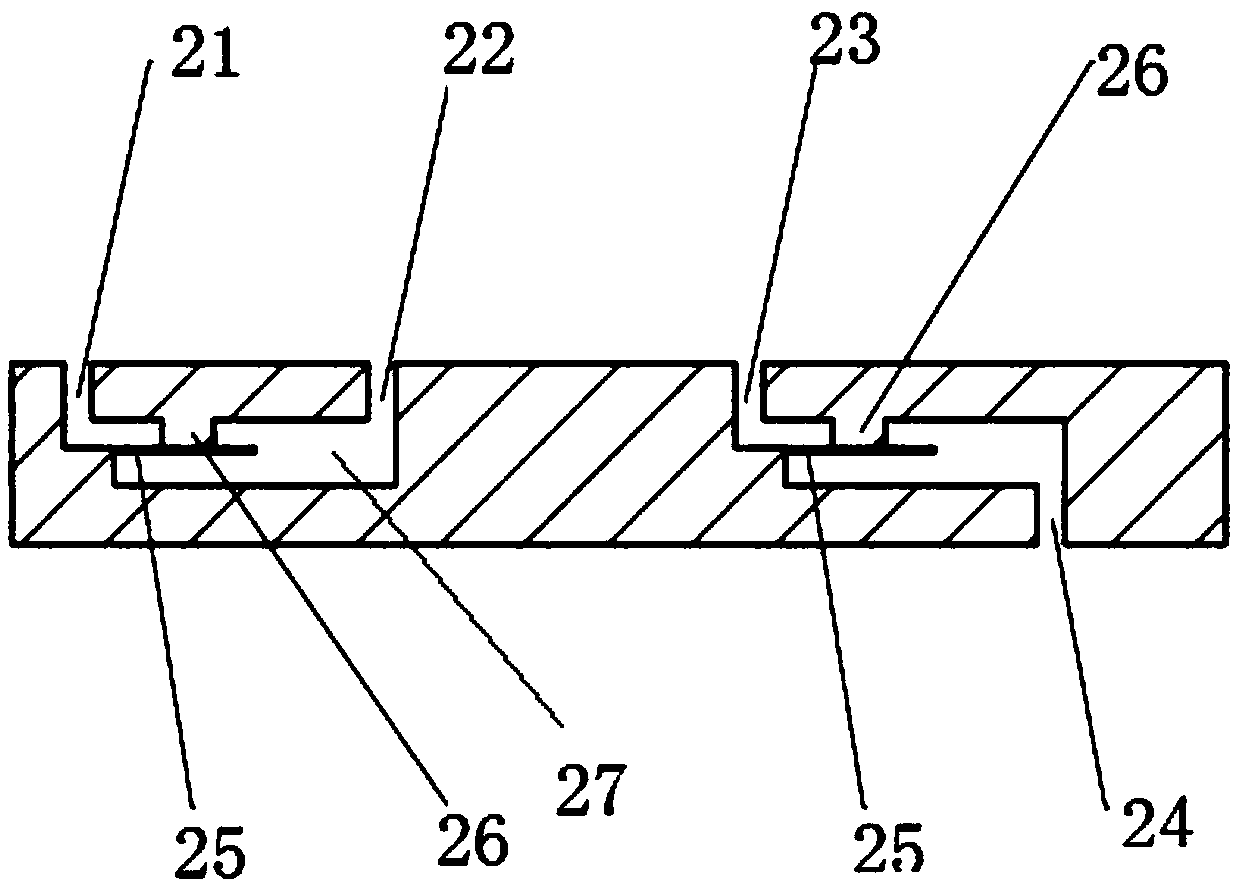

[0032] Such as Figure 1-5 As shown, the precision micropump driven by air pressure includes an air pressure module 1 , a one-way valve group 2 , a liquid storage module 3 and a flow regulation module 4 .

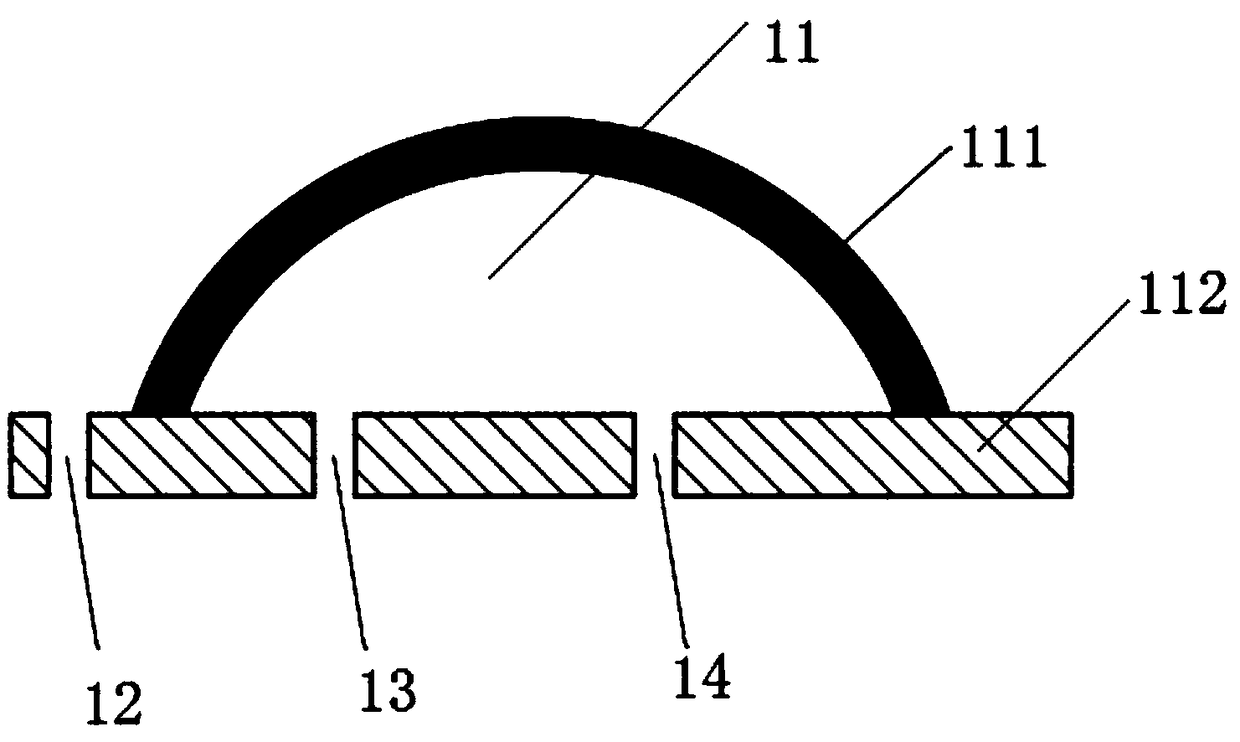

[0033] The air pressure module 1 is provided with an air bag 11, an outer hole 12, a first inner hole 13 and a second inner hole 14; the air bag 11 is surrounded by a bottom plate 112 and a curved wall 111, and the curved wall 111 is made of an elastic material, which can be restored to its original shape after extrusion. The bottom plate is connected with the one-way valve group 2. The bottom plate 111 is provided with an outer hole 12, a first inner hole 13 and a second inner hole 14. The outer hole 12 leads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com