Segment transportation device and operation method for shield tunneling with tunnel diameter less than six meters

A technology of transportation device and segment assembly machine, which is applied in the direction of tunnel, tunnel lining, shaft equipment, etc., which can solve the problem of segment transportation and pick-up position with narrow space, unable to accommodate the secondary segment crane or feeder, handling Low segment efficiency and other issues, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

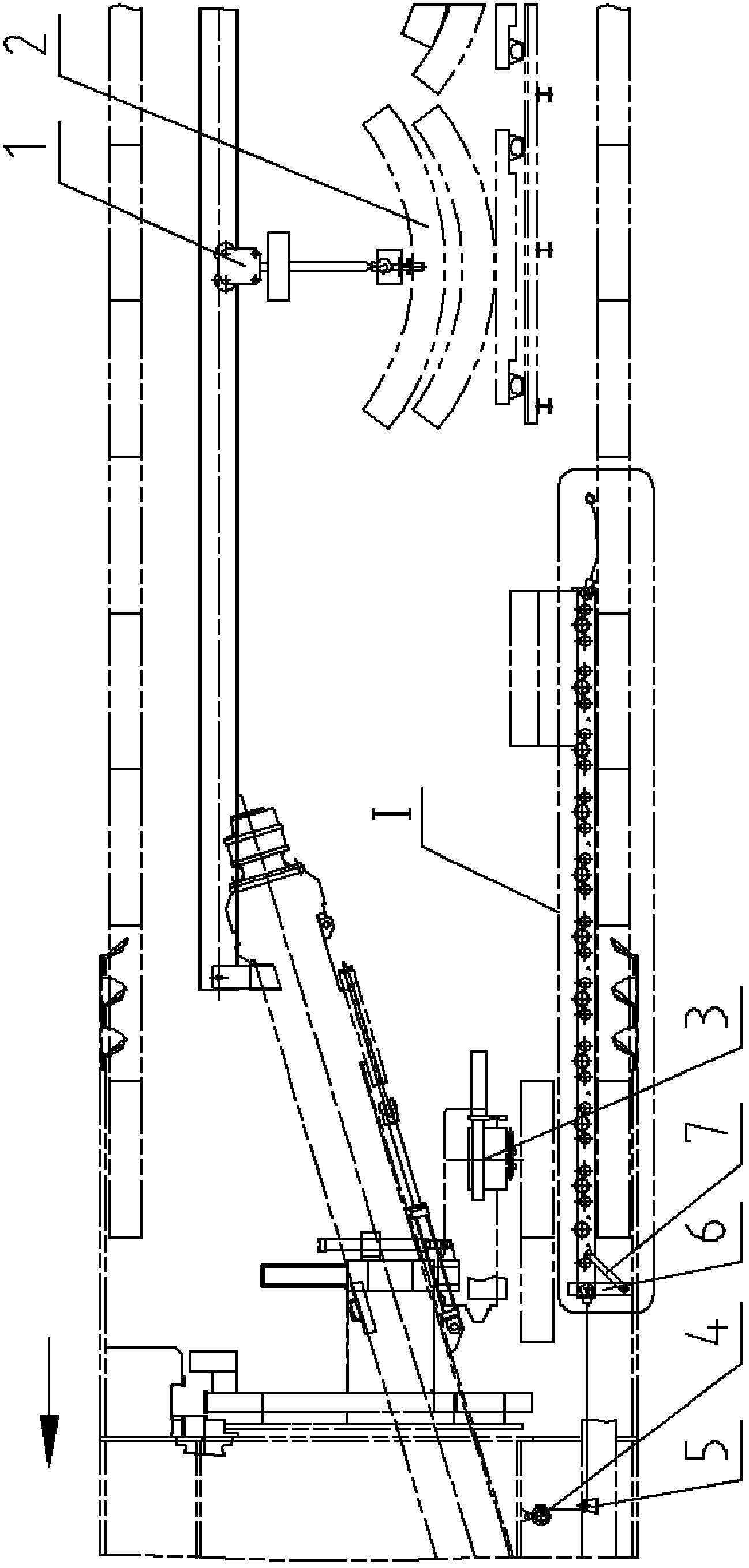

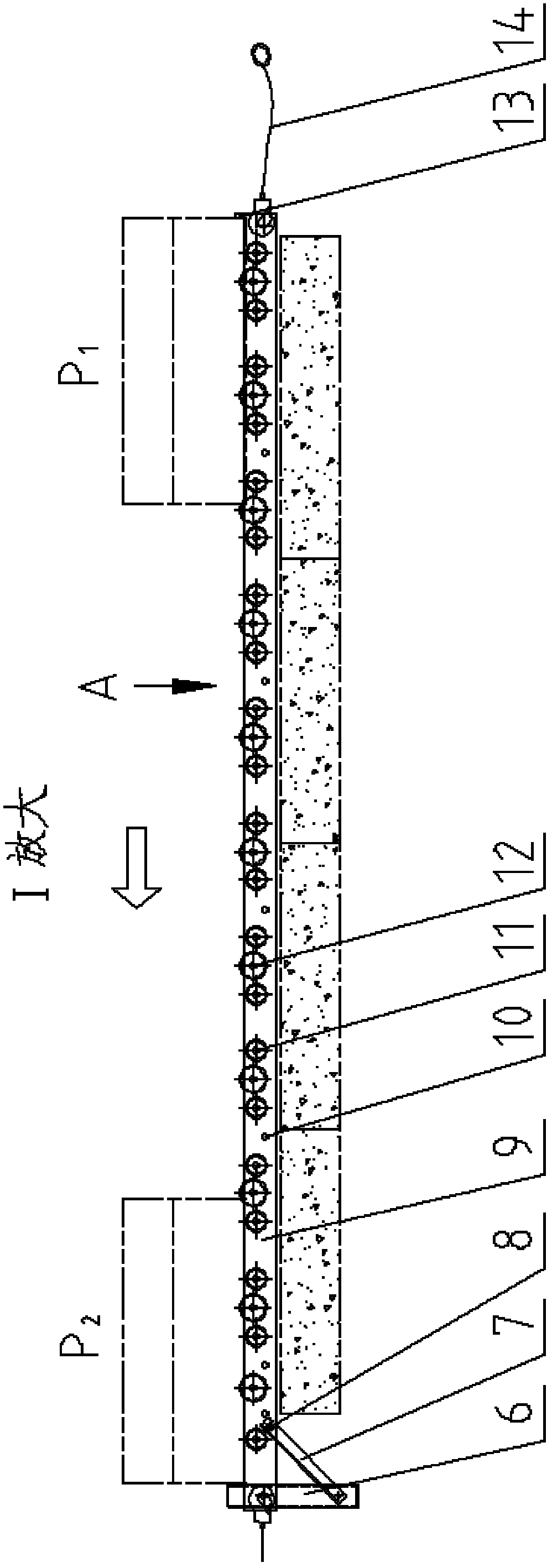

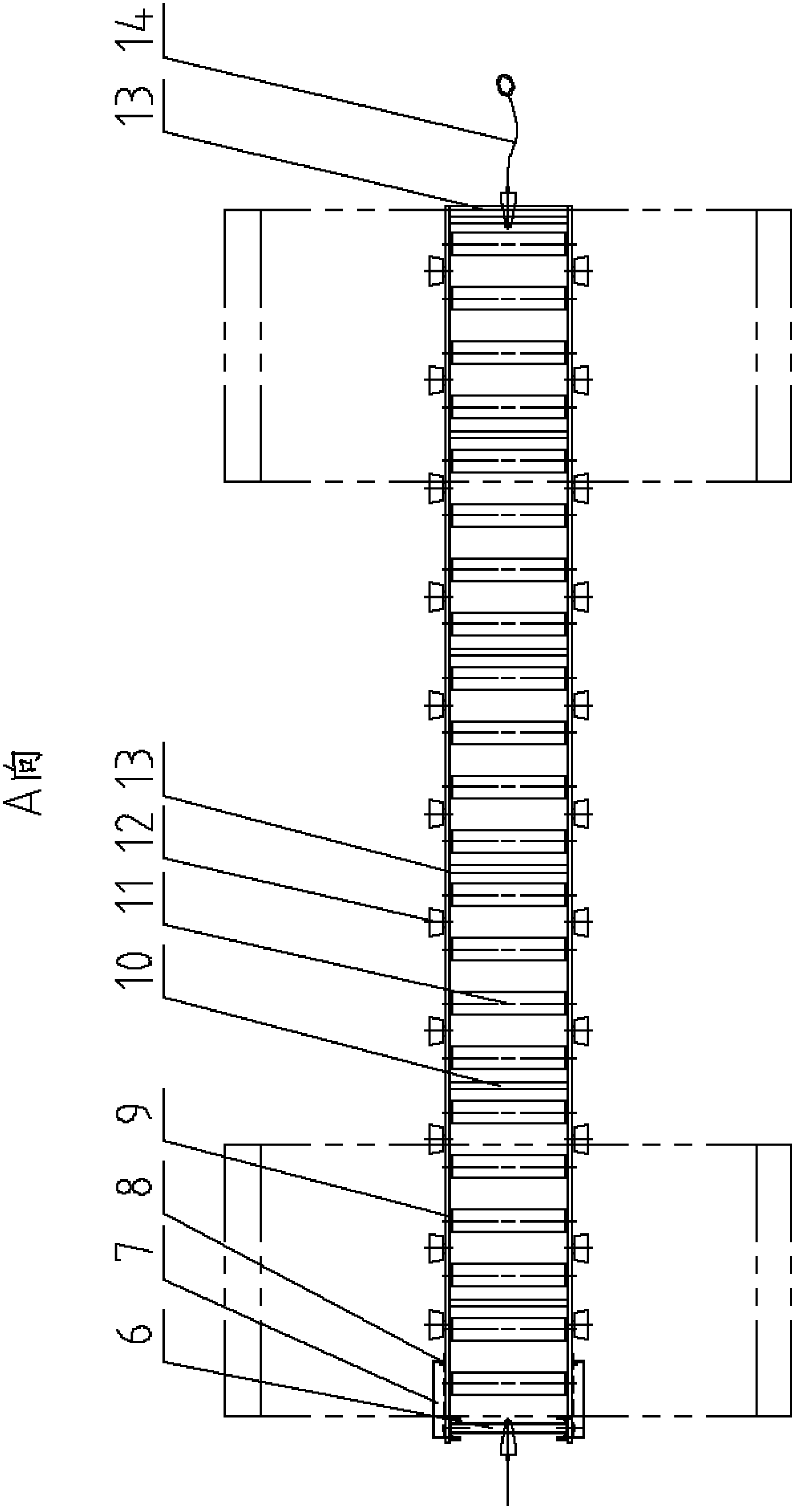

[0033] figure 1 , 2 Shown in , 3 is one of embodiments of the present invention, and it is the tunnel diameter that installs in the φ 4.16 meter tunnel shield construction that certain city underground electric power line is used less than the segment transportation device that the six meter shield construction is used, Among them, the bearing segment roller table adopts a sliding bearing roller table; its structure includes a segment crane 1 and a segment assembly machine 3, and is characterized in that: in the tunnel between the segment crane 1 and the segment assembly machine 3 The bottom surface is equipped with a segment conveyer composed of a crane combined drive mechanism, a segment roller table and a support mechanism, wherein the crane combined drive mechanism is composed of a front drag mechanism and a rear pull mechanism, and the front drag mechanism consists of The hoist crane 4 and the fixed pulley 5 are composed of a support mechanism installed in the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com