Wood gluing device

A gluing device, wood technology, applied in the direction of adhesive application device, wood processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, discontinuous manual gluing operation, etc., to achieve the effect of improving efficiency and continuous gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

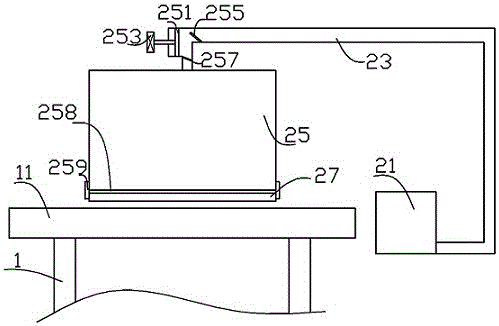

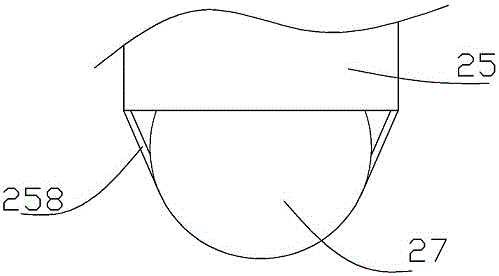

[0020] Such as figure 1 and figure 2 The shown wood gluing device includes a gluing mechanism and a gluing mechanism, the gluing mechanism includes a frame 1 and a workbench 11, and the workbench 11 is connected above the frame 1, wherein the gluing mechanism includes a glue storage tank 21, The rubber delivery pipe 23, the rubber storage box 25 and the rubber brush roller 27, the rubber storage pool 21 is connected with the rubber storage box 25 through the rubber delivery hose 23, the rubber delivery hose 23 is provided with a piston 251, the piston 251 is connected with the cylinder 253, and the rubber delivery hose 23 is close to the storage One side of the glue pool 21 is provided with a first one-way valve 255 and a side close to the glue storage box 25 is provided with a second one-way valve 257, the two sides of the bottom end of the glue storage box 25 are connected with connecting rods 259, and the rubber brush roller 27 The two ends of the connecting rod 259 are r...

Embodiment 2

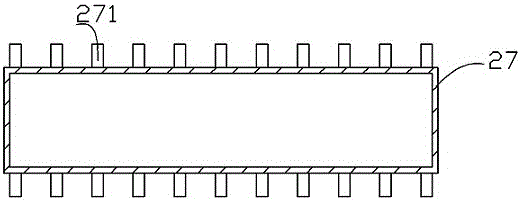

[0023] Such as image 3 As shown, the difference from Embodiment 1 is that the outer surface of the brush roller 27 is connected with bristles 271 . By setting the bristle 271 on the brush rubber roller 27, the glue in the glue storage box 25 is adsorbed on the brush rubber roller 27 by the adsorption of the brush hair 271, which ensures the glue brushing operation of the brush rubber roller 27 to wood.

Embodiment 3

[0025] Such as Figure 4 As shown, the difference from Embodiment 1 or Embodiment 2 is that the outer surface of the rubber brushing roller 27 is covered with a soft rubber brushing sleeve 273 . Set a soft rubber brushing sleeve 273, utilize the compressibility of the rubber brushing sleeve 273 to block the contact between the rubber storage box 25 and the rubber brushing roller 27, when the rubber brushing roller 27 rotates, the rubber brushing sleeve 273 is received by the rubber storage box The pressure compression of 25 sidewalls makes the rubber brushing roller 27 continue to rotate, avoiding the waste of glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com