Discharging belt system with rotating and pitching movements

A technology of unloading belt and pitching motion, which is used in transportation and packaging, conveyor objects, supporting frames, etc., can solve the problems of complex slewing mechanism and the unloading belt system cannot perform autonomous slewing motion, etc. Compact structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

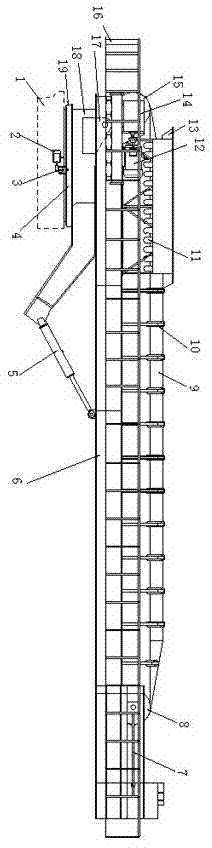

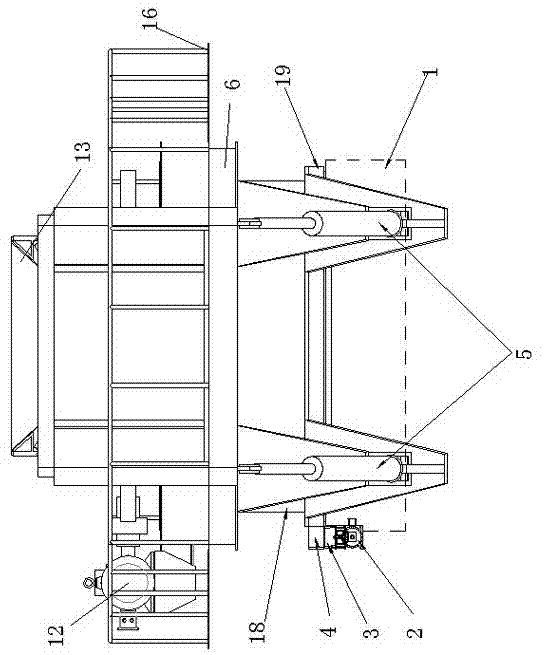

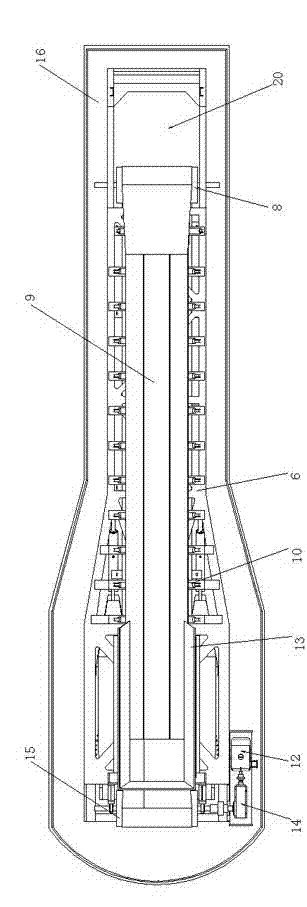

[0019] The invention discloses a discharge belt system with slewing and pitching motions. The system is composed of a pitching double hydraulic cylinder support device, a slewing drive mechanism, a belt 9, a slewing base 18, and a slewing support 19. The specific structure is shown in figure 1 , figure 2 and image 3 , the main body of the unloading belt system is a steel structure frame 1, the steel structure frame 1 is a cantilever beam, one end is hinged to the bottom of the rotary base 18 through the hinged support assembly 17, and the other end is hinged to one end of the piston rod of the pitching double hydraulic cylinder. The pitch angle of the steel structure frame 1 is: -15 to +15 degrees, and the rotation angle is: -90 to +90 degrees.

[0020] The supporting device of the double hydraulic cylinders for pitching refers to the double hydraulic cylinders for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com