Filling wall body capable of protecting laneway through soft yielding in non-chain-pillar filling mining and construction method thereof

A technology for filling walls and construction methods, which is applied to fillings, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor yielding effect, difficult construction, complex structure, etc., and achieve slow resistance increase, simple construction, and low The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] Step 1: Calculate the height h of the expansive organic foam filling wall 1 Height h of similar paste filling body 2 :

[0050]

[0051]

[0052] Where: h 1 -predicted value of roof subsidence, in m;

[0053] h 2 -predicted value of roof subsidence, in m;

[0054] l- width of lane retention, unit m;

[0055] L - the span of the old top rock beam, in m;

[0056] h-mining height, unit m;

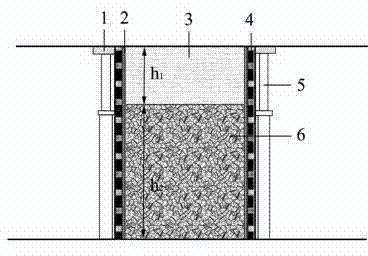

[0057] Step 2: After the coal mining face is mined, retain the roadway according to the existing roadway filling method, and use double-row metal hinged roof beams (1) and single hydraulic props (5) to strengthen the roof support beside the roadway, and the inner side of the single hydraulic prop Install the filling formwork (4), and install the cord (2) inside the formwork;

[0058] Step 3: Fill the inner side of the curtain with paste-like filling material (6) to a height of h 2 , the paste-like filling wall is composed of a mixture of water, cement, fly ash, river sand...

Embodiment 3

[0062] Step 1: Calculate the height h of the expansive organic foam filling wall 1 Height h of similar paste filling body 2 :

[0063]

[0064]

[0065] Where: h 1 -predicted value of roof subsidence, in m;

[0066] h 2 -predicted value of roof subsidence, in m;

[0067] l- width of lane retention, unit m;

[0068] L - the span of the old top rock beam, in m;

[0069] h-mining height, unit m;

[0070] Step 2: After the coal mining face is mined, retain the roadway according to the existing roadway filling method, and use double-row metal hinged roof beams (1) and single hydraulic props (5) to strengthen the roof support beside the roadway, and the inner side of the single hydraulic prop Install the filling formwork (4), and install the cord (2) inside the formwork;

[0071] Step 3: Fill the inner side of the curtain with paste-like filling material (6) to a height of h 2 , the paste-like filling wall is composed of a mixture of water, cement, fly ash, river sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Uniaxial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com