Sharp inclined coal seam paste filling mining technology

A paste filling and steep inclination technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve problems such as difficulty in controlling the roof and floor of the coal seam, difficulty in managing the working face, and coal wall pieces, etc., to protect groundwater resources, prevent The effect of surface subsidence, increasing mine production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

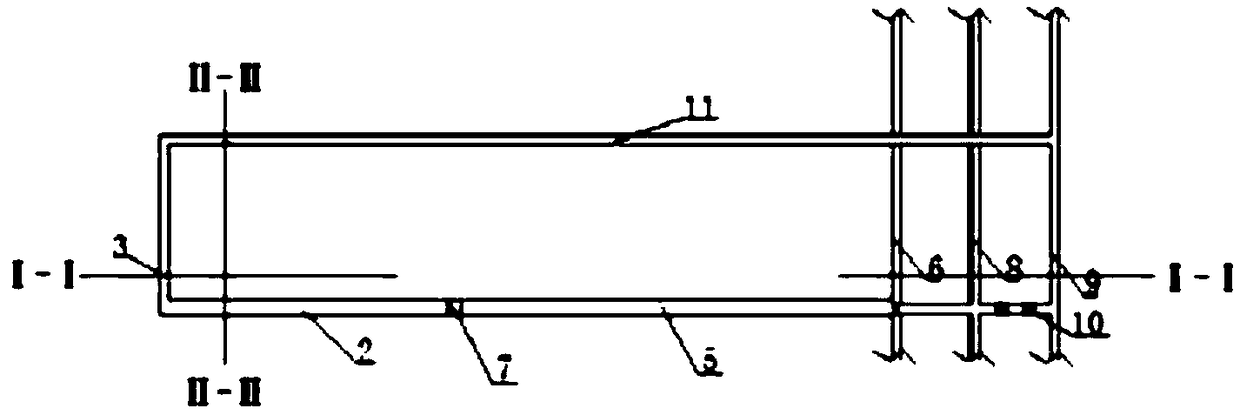

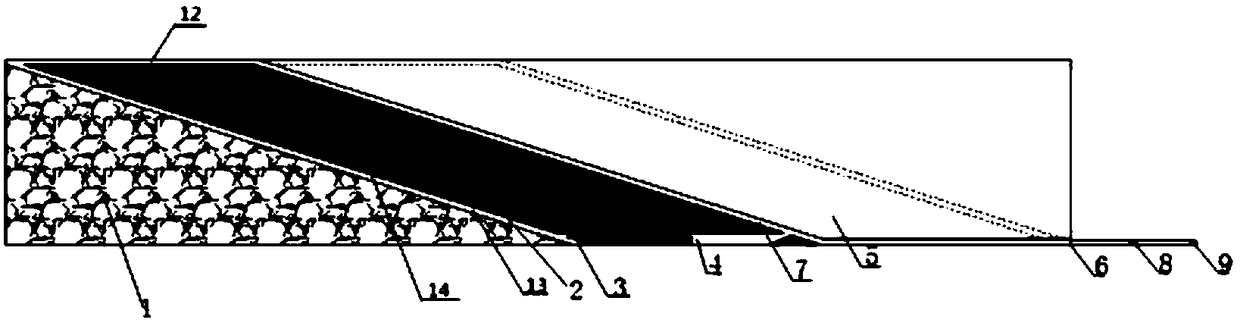

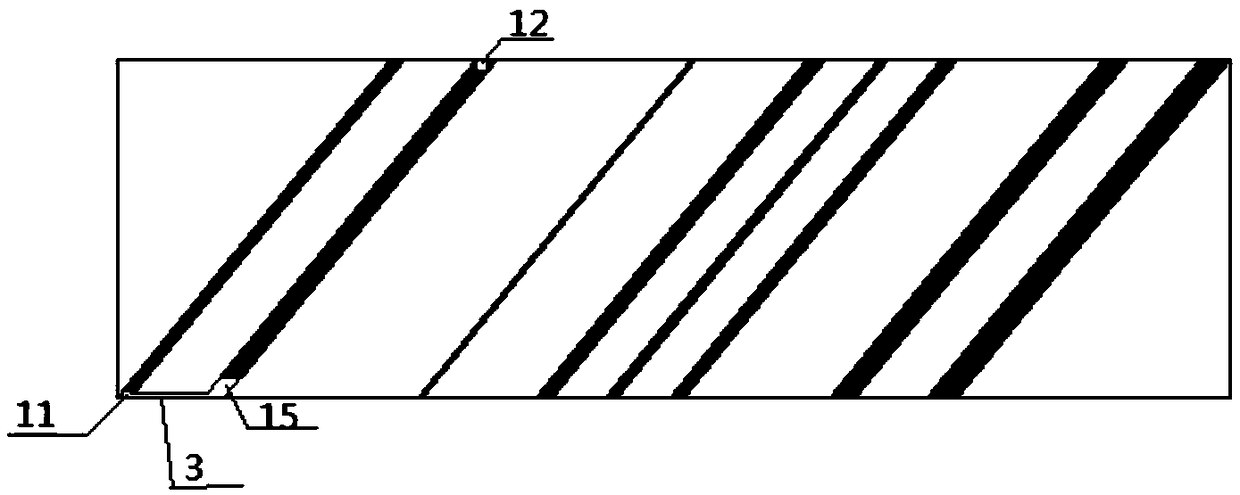

[0028] Embodiment 1 A kind of steeply inclined coal seam paste filling coal mining method

[0029] (1) In the underground transportation roadway 6, move towards the opening along the back mining coal seam 14, and transport the tunnel 7 up the mountain at 16°, and the transportation tunnel 7 of the working surface is used for coal transportation and the ventilation roadway of the working surface, to be excavated to the mine When designing the upper limit of the mining elevation, excavate the level roadway, that is, the cutting eye of the working face 12;

[0030] (2) Excavate the return airway 11 from the underground air return road 9 along the opening of the adjacent coal seam 2 of the mining coal seam working face, and the excavation direction is parallel to the mining working face 2. The return air stone gate 3 is connected with the return air trough 13 of the mining face to form a ventilation and material transportation system for the mining face;

[0031] (3) Excavate alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com