Underground mining, selecting and filling synergic mining method for close distance coal seam group

A mining method and short-distance technology, applied in underground mining, filling, surface mining, etc., to achieve the effect of increasing the clean coal lifting rate, relieving the main lifting pressure, and saving tons of coal lifting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

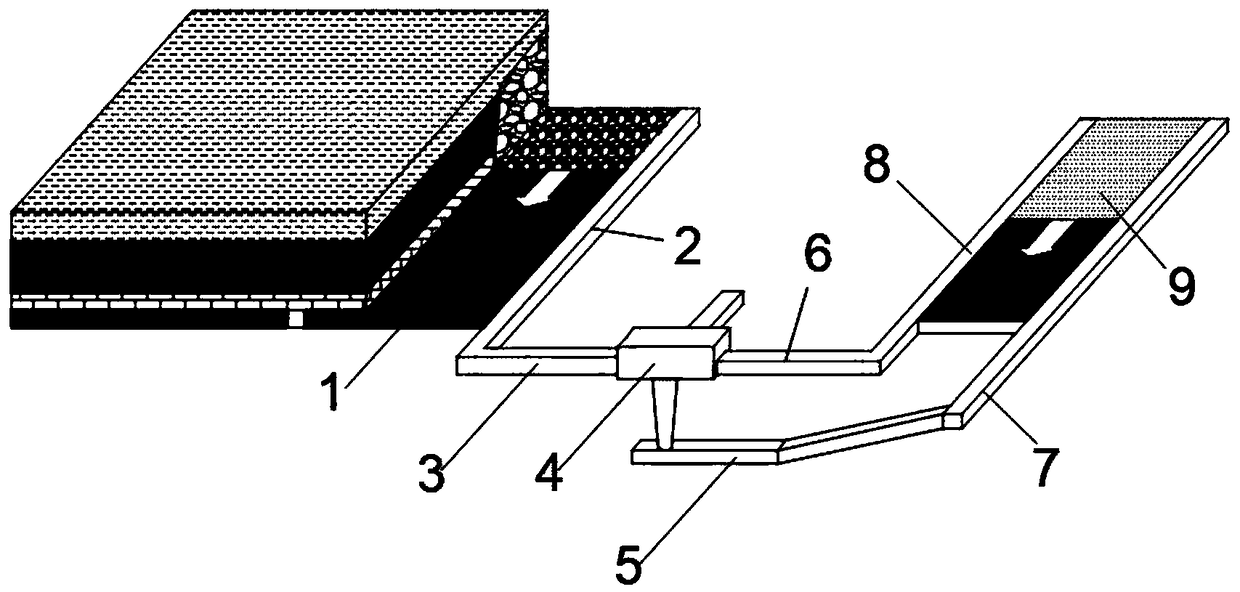

[0021] Attached below figure 1 An embodiment of the present invention is further described:

[0022] Such as figure 1 Shown, the short-distance coal seam group underground mining of the present invention chooses and fills the collaborative mining method, and its steps are as follows:

[0023] a. Design fully-mechanized caving working face 1, and design filling working face 9 in a suitable mining area according to the annual gangue output in the mining area, wherein the total thickness of the gangue layer in the coal seam group near the mining area is not greater than 2.0m, and the thickness of a single layer of gangue is not greater than 1.0m, according to the specific conditions, certain measures can be taken on the gangue layer to increase the risk of release; on both sides of the filling face 9, the section transport lane II8 and the section return air lane 7 are respectively set; the position of the filling face 9, It should be selected in the mining area that does not h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com