Forward tilting self-unloading-type car dumper

A dumper and self-unloading technology, which is applied in the field of mining machinery, can solve the problems of huge initial investment and later investment, large equipment dimensions, occupation of vehicles and labor, etc., to achieve compact structure, small occupation of space, and avoid safety accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

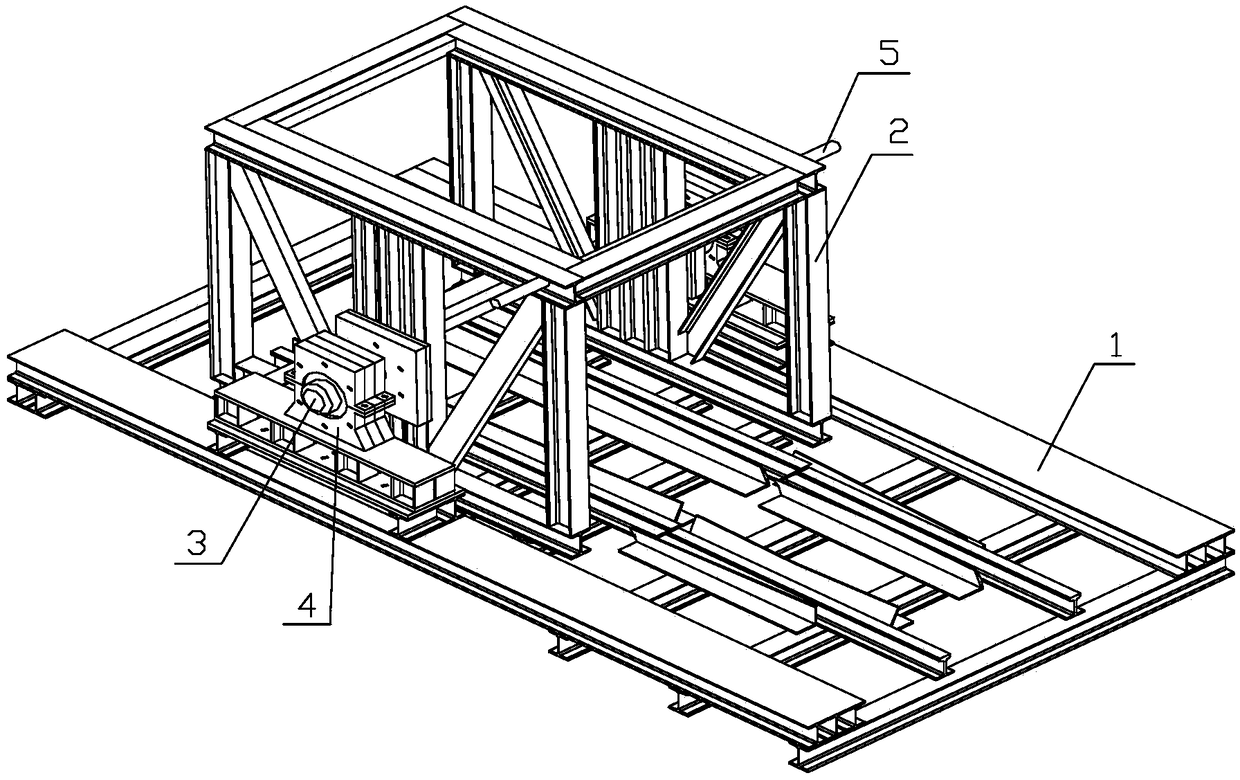

[0029] like figure 1 As shown, a forward tilting self-unloading dumper includes a platform 1 and a tilting cage assembly. Vehicles with gangue or industrial waste in the roadway enter the dumping cage assembly through the platform 1. The dumping cage assembly is located above the platform 1, and its Rotatingly connected with the platform 1, the tilting cage component drives the vehicle to turn over to realize unloading of the vehicle.

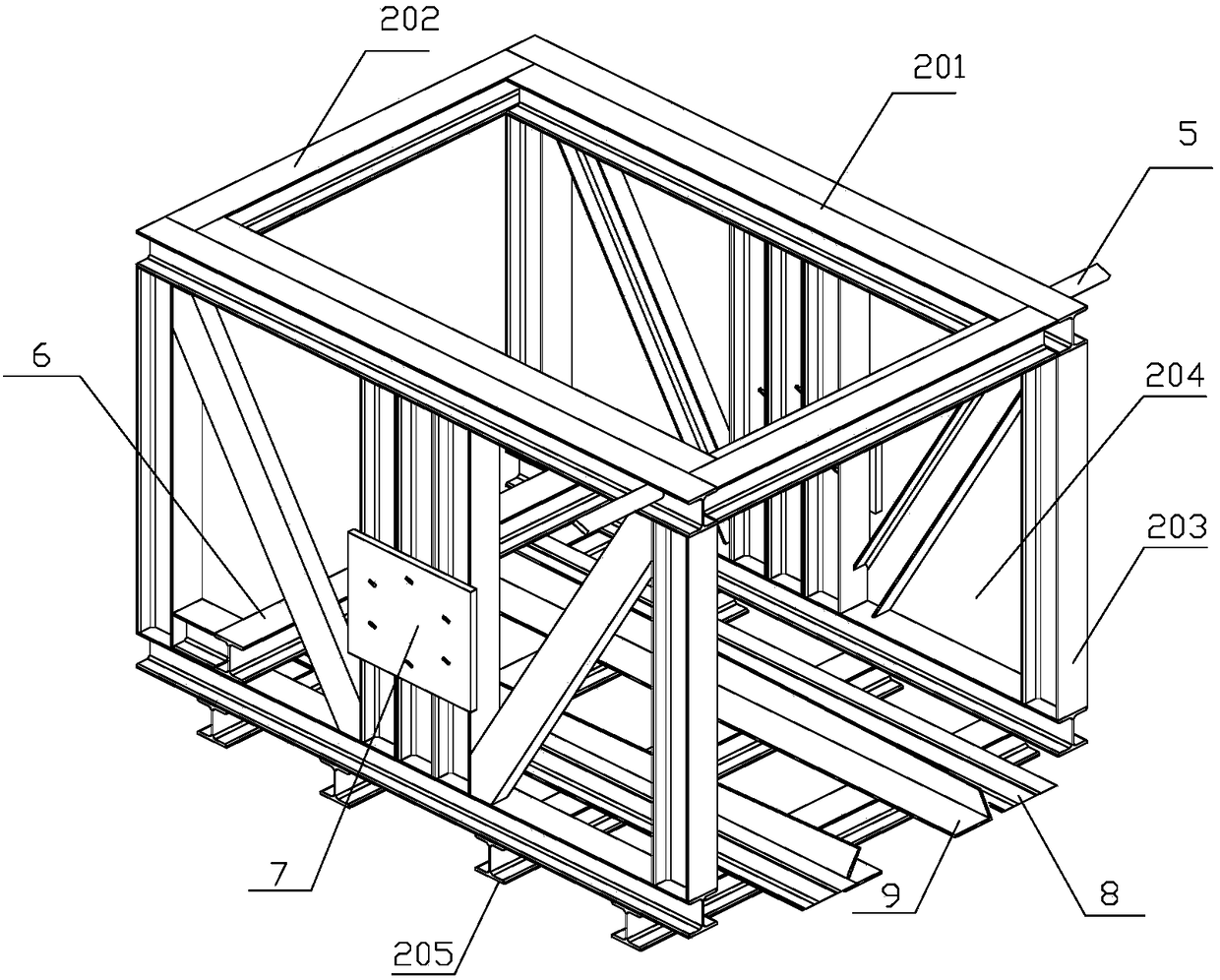

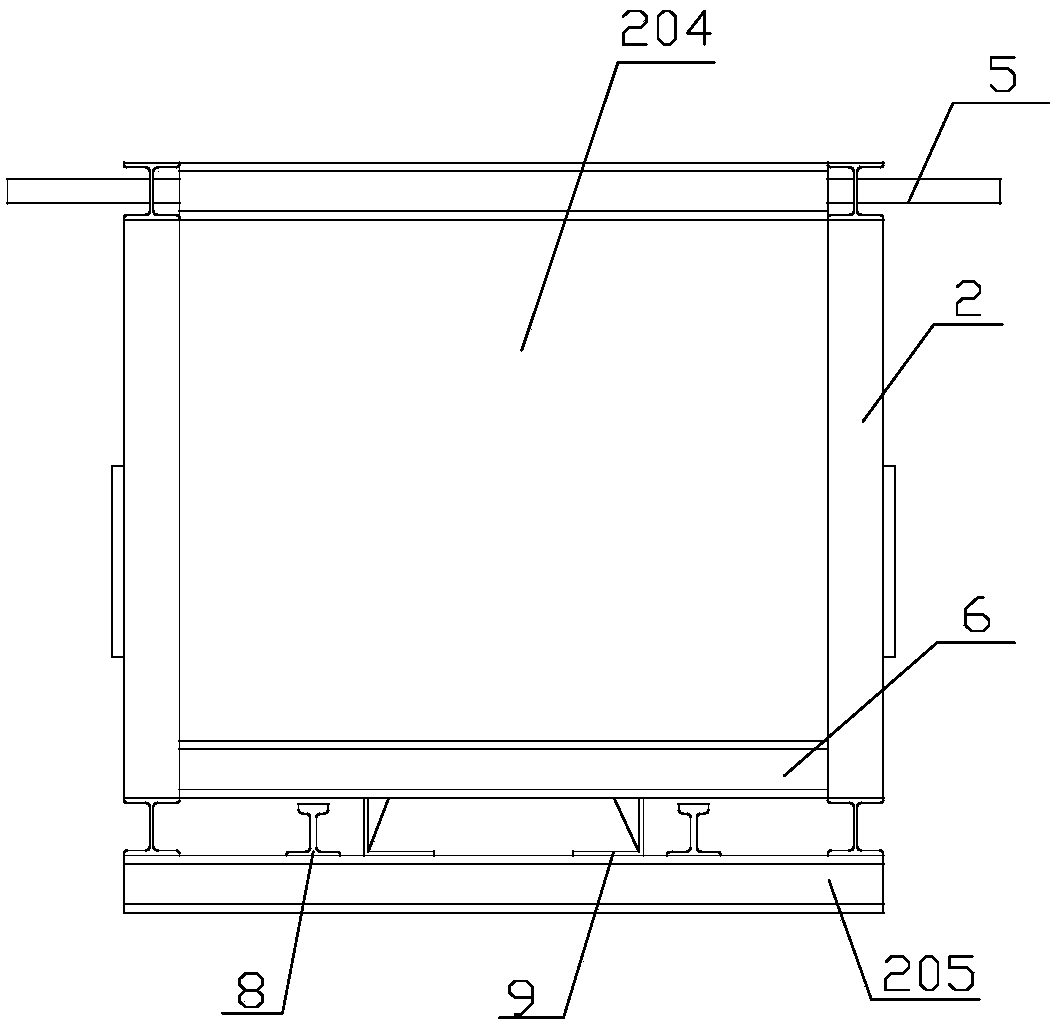

[0030] like Figure 1-3 As shown, the cage assembly includes a cage body 2, a bearing set and a limit shaft 5, and the cage body 2 is surrounded by a plurality of cage body beams 202, cage body long beams 201 and cage body vertical beams 203 in sequence. It is a three-dimensional frame structure, one side of which is provided with an entrance 204 for vehicles to drive, and the other side is provided with a vehicle resistance beam 6 for preventing vehicles from running at a place corresponding to the entrance 204, and the vehicle resistance bea...

Embodiment 2

[0037] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0038] like figure 1 , Figure 4 and Figure 7-8As shown, when the inclined roadway 21 needs to be filled, the forward tipping dumper also includes a transition platform assembly 15 and a lap joint 16, one end of the transition platform assembly 15 is movably connected to the lap joint 16, and the other end is connected to the lap joint 16. The platforms 1 are connected, and the lap joint 16 is placed above the inclined roadway 21, and the vehicle enters the cage body 2 after passing through the transition platform assembly 15 to form a gentle slope from the inclined roadway 21, which can also realize gangue backfilling and has strong practicability.

[0039] The transition platform assembly 15 includes a support plate 19, a base plate 18 and a support beam 20, the support plate 19 is arranged along a horizontal plane, the base plate 18 is located below the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com