Efficient and intelligent dust removal system for mine

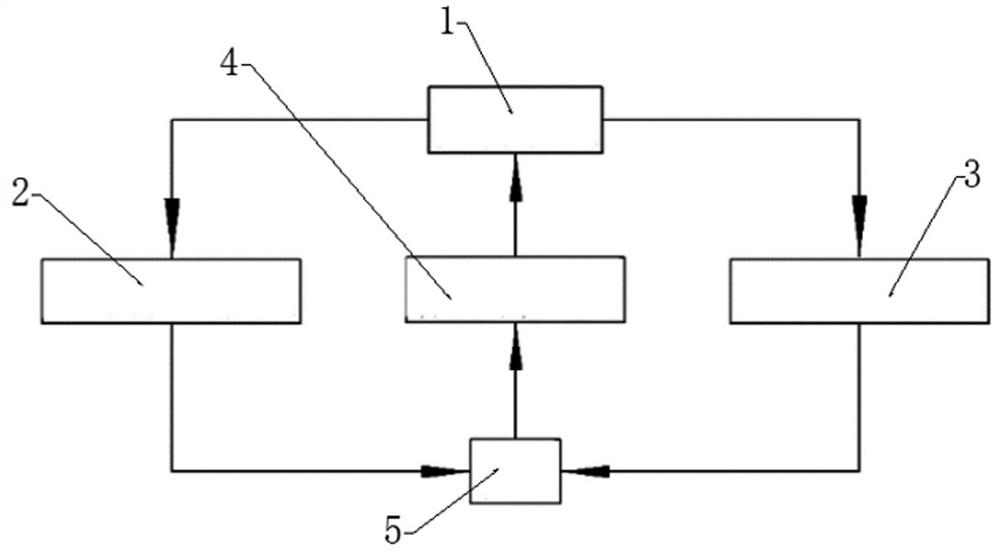

A dust removal system and high-efficiency technology, applied in dust prevention, mining equipment, mining equipment, etc., can solve the problems of fan dust removal noise, low foam dust removal efficiency, etc., to achieve high dust removal efficiency, optimal energy consumption and utilization, and safety The effect of a comfortable production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

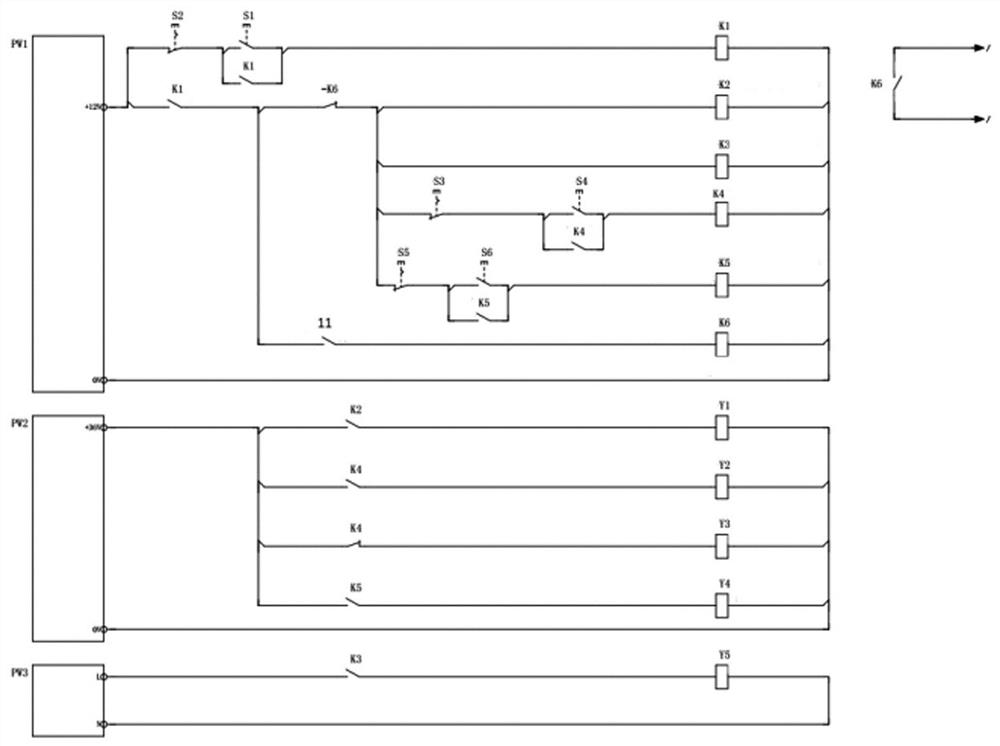

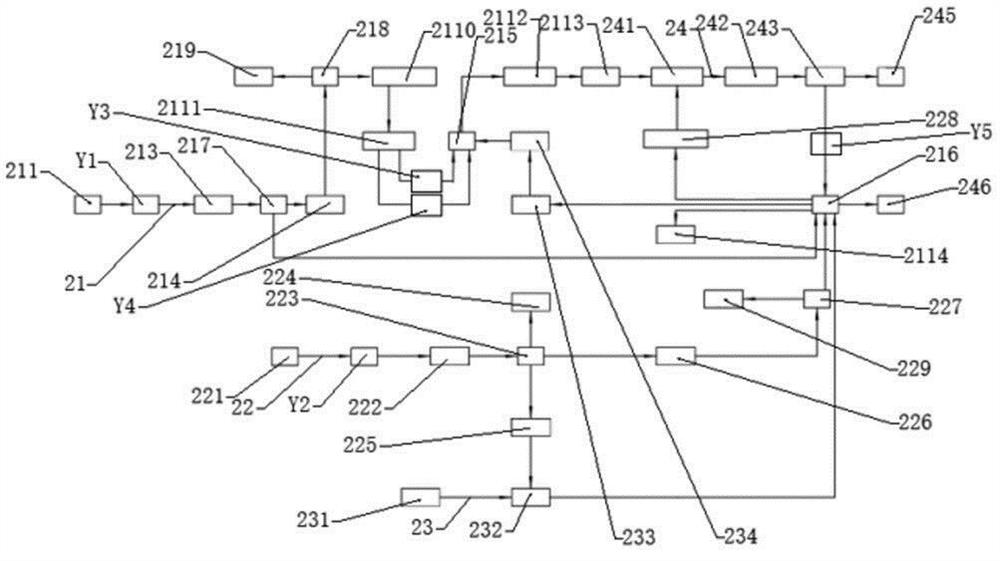

Embodiment 1

[0049] The 15204 working face of Shanxi Yangmei Group Pingshu Coal Industry Co., Ltd. uses the present invention, in which the model of the foam dust removal device is PY7000, the model of the fan dust removal device is KCS-500D, the model of the dust sensor is GCD1000, and the control device includes the component DF20 4 / 10 type explosion-proof solenoid valves: 2 of which are DN10 interfaces, 1 is DN6 interface, and 1 is DN25 interface, 2 MKD-1 mining intrinsically safe power supplies: 1 output DC24V and 1 output DC12V, 1 LRS-200-36 switching power supply, 6 LY2N-J intermediate relays, 1 AH0.6 / 12 mine intrinsically safe button box, 1 QMB3.5-1.25G mine high-voltage small-diameter special valve indivual.

[0050] After using the invention, the dust reduction efficiency at the driver's position reaches 97.8%, the dust reduction efficiency at the 2m position of the roadheader is 97.4%, the dust reduction efficiency at the second running point reaches 95.6%, and the dust reductio...

Embodiment 2

[0052] The 15110 working face of Shanxi Yangmei Group Pingshu Coal Industry Co., Ltd. uses the present invention, in which the model of the foam dust removal device is PY7000, the model of the fan dust removal device is KCS-400D, the model of the dust sensor is GCD1000, and the control device includes the component DF20 4 / 10 type explosion-proof solenoid valves: 2 of which are DN10 interfaces, 1 is DN6 interface, and 1 is DN25 interface, 2 MKD-1 mining intrinsically safe power supplies: 1 output DC24V and 1 output DC12V, 1 LRS-200-36 switching power supply, 6 LY2N-J intermediate relays, 1 AH0.6 / 12 mine intrinsically safe button box, 1 QMB3.5-1.25G mine high-voltage small-diameter special valve indivual.

[0053] After using the invention, the dust reduction efficiency at the driver's position reaches 97.6%, the dust reduction efficiency at the 2m position of the roadheader is 97.2%, the dust reduction efficiency at the second running point reaches 95.5%, and the dust reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com