Method for improving caustic ratio of Barer process seeded precipitation mother solution

A technology of causticity ratio and Bayer method, which is applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., which can solve the problem of declining process indicators, production efficiency decline, and alumina output rate Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

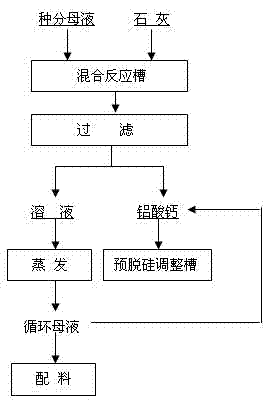

[0013] Lime is added to the mother liquid of seed separation after Bayer method seed separation (molecular ratio CaO:AL 2 o 3 1:1), stirred in the mixing reaction tank for 30 minutes, entered the filter for filtration, and the filtrate was evaporated in the evaporation process, and then used as a circulating mother liquor to dissolve the next batch of bauxite. The method circulates the mother liquor to the pre-desilication adjustment tank, adjusts the solid content of the desilication slurry and plays the role of replacing part of the lime after adding.

Embodiment 2

[0015] Add lime to the mother liquor after Bayer method seed separation (molecular ratio CaO: AL 2 o 3 It is 2:1), stirring in the mixing reaction tank for 20 minutes, entering the filter for filtration, and the filtrate is evaporated in the evaporation process, and then used as a circulating mother liquor to dissolve the next batch of bauxite. The solid substance calcium aluminate uses Bayer The method circulates the mother liquor to the pre-desilication adjustment tank, adjusts the solid content of the desilication slurry and plays the role of replacing part of the lime after adding.

Embodiment 3

[0017] Add lime to the mother liquor after Bayer method seed separation (molecular ratio CaO: AL 2 o 3 It is 3:1), stirring in the mixing reaction tank for 10 minutes, entering the filter for filtration, and the filtrate is evaporated in the evaporation process, and then used as a circulating mother liquor to dissolve the next batch of bauxite. The solid substance calcium aluminate uses Bayer The method circulates the mother liquor to the pre-desilication adjustment tank, adjusts the solid content of the desilication slurry and plays the role of replacing part of the lime after adding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com