A method for preparing ceramsite proppant from bauxite beneficiation tailings

A technology of bauxite and proppant, which is applied in earth cube drilling, wellbore/well components, mining fluids, etc., can solve problems such as high management and maintenance costs, increased economic burden, and huge infrastructure investment, achieving significant economic benefits and Social benefits, good market promotion prospects, and low alumina content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

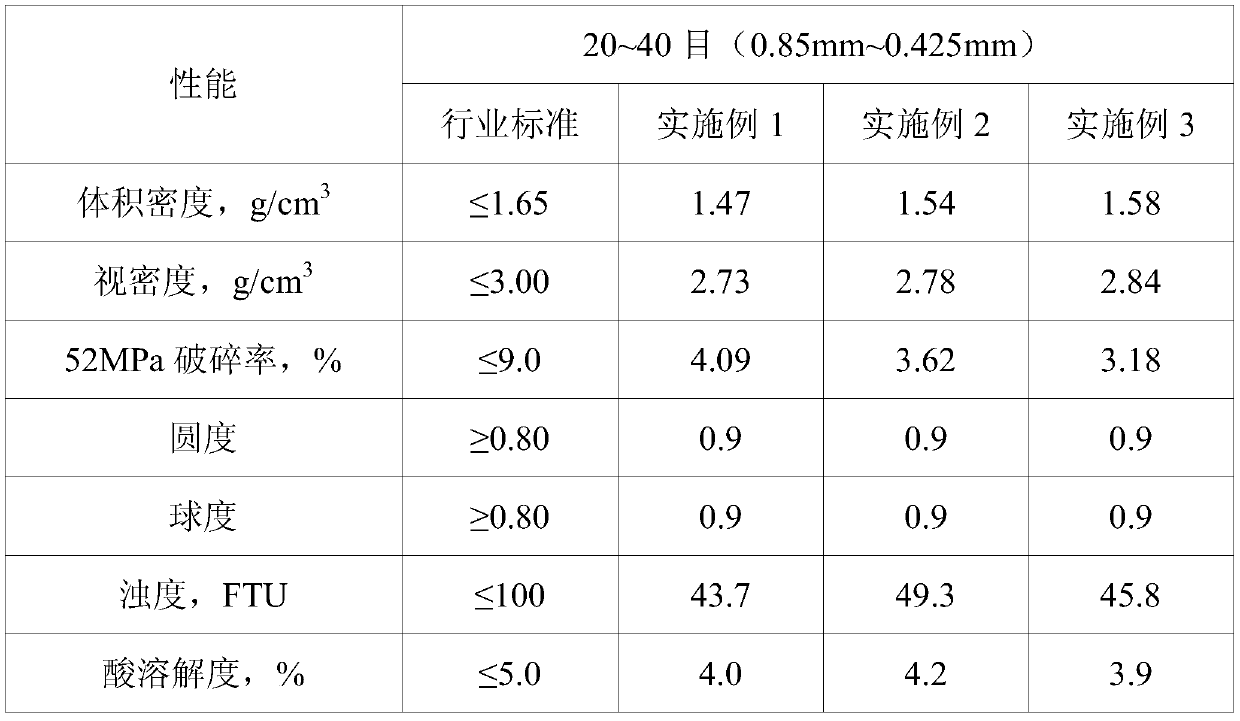

Examples

Embodiment 1

[0027] A bauxite beneficiation tailings in Shanxi, the weight percentage of its main chemical composition is: Al 2 o 3 : 38.16%; SiO 2 : 44.45%; Fe 2 o 3 : 2.80%; TiO 2 : 1.86%; K 2 O: 0.15%; Na 2 O: 0.05%; CaO: 0.14%; MgO: 0.12%. Using the bauxite dressing tailings as the main raw material to prepare low-density and high-strength ceramsite proppant, the main process steps are:

[0028] (1) The bauxite beneficiation tailings are subjected to iron removal by a high gradient magnetic separator, and the iron-removing product Fe is low 2 o 3 The content is 1.02%.

[0029] (2) Pre-burn the bauxite tailings after iron removal at 700°C for 3 hours, and then add aluminum phosphate as an additive for batching. The additive dosage is 4.5% of the total weight of raw materials. Less than 400 mesh (0.0374mm).

[0030] (3) Complete the granulation of the material in step (2) with a forced-stirring granulator to make semi-finished granules of 18-35 mesh (1.00mm-0.50mm);

[0031] ...

Embodiment 2

[0034]A bauxite beneficiation tailings in Henan, the weight percentage of its main chemical composition is: Al 2 o 3 : 49.80%; SiO 2 : 24.65%; Fe 2 o 3 : 4.82%; TiO 2 : 2.82%; K 2 O: 0.26%; Na 2 O: 0.16%; CaO: 0.25%; MgO: 0.14%. Using the bauxite dressing tailings as the main raw material to prepare low-density and high-strength ceramsite proppant, the main process steps are:

[0035] (1) The bauxite beneficiation tailings are subjected to iron removal by a high gradient magnetic separator, and the iron-removing product Fe is low 2 o 3 The content is 1.42%.

[0036] (2) Pre-burn the bauxite dressing tailings after iron removal at 800°C for 2 hours, then add polyaluminum chloride as an additive for batching, the additive dosage is 2.5% of the total weight of raw materials, and the fine powder after batching The powder particle size is less than 400 mesh (0.0374mm).

[0037] (3) Complete the granulation of the material in step (2) with a forced-stirring granulator to ...

Embodiment 3

[0041] A bauxite beneficiation tailings in Guizhou, the weight percentage of its main chemical composition is: Al 2 o 3 : 54.78%; SiO 2 : 22.11%; Fe 2 o 3 : 2.88%; TiO 2 : 2.75%; K 2 O: 0.38%; Na 2 O: 0.01%; CaO: 0.35%; MgO: 0.12%. Using the bauxite dressing tailings as the main raw material to prepare low-density and high-strength ceramsite proppant, the main process steps are:

[0042] (1) The bauxite beneficiation tailings are subjected to iron removal by a high gradient magnetic separator, and the iron-removing product Fe is low 2 o 3 The content is 1.22%.

[0043] (2) Pre-burn the bauxite tailings after iron removal at 900°C for 1.5 hours, then add sodium silicate as an additive for batching, the additive dosage is 0.5% of the total weight of raw materials, and the fine powder after batching The particle size is less than 400 mesh (0.0374mm).

[0044] (3) Complete the granulation of the material in step (2) with a forced-stirring granulator to make semi-finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com