Method for synthesizing hydrated calcium chloroaluminate from municipal refuse incineration fly ash

A technology of calcium chloroaluminate hydrate and incineration of fly ash, which is applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, can solve the problems of strict condition control, inconvenient large-scale production, and complex synthesis methods, etc. Achieve the effect of the potential of the large environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

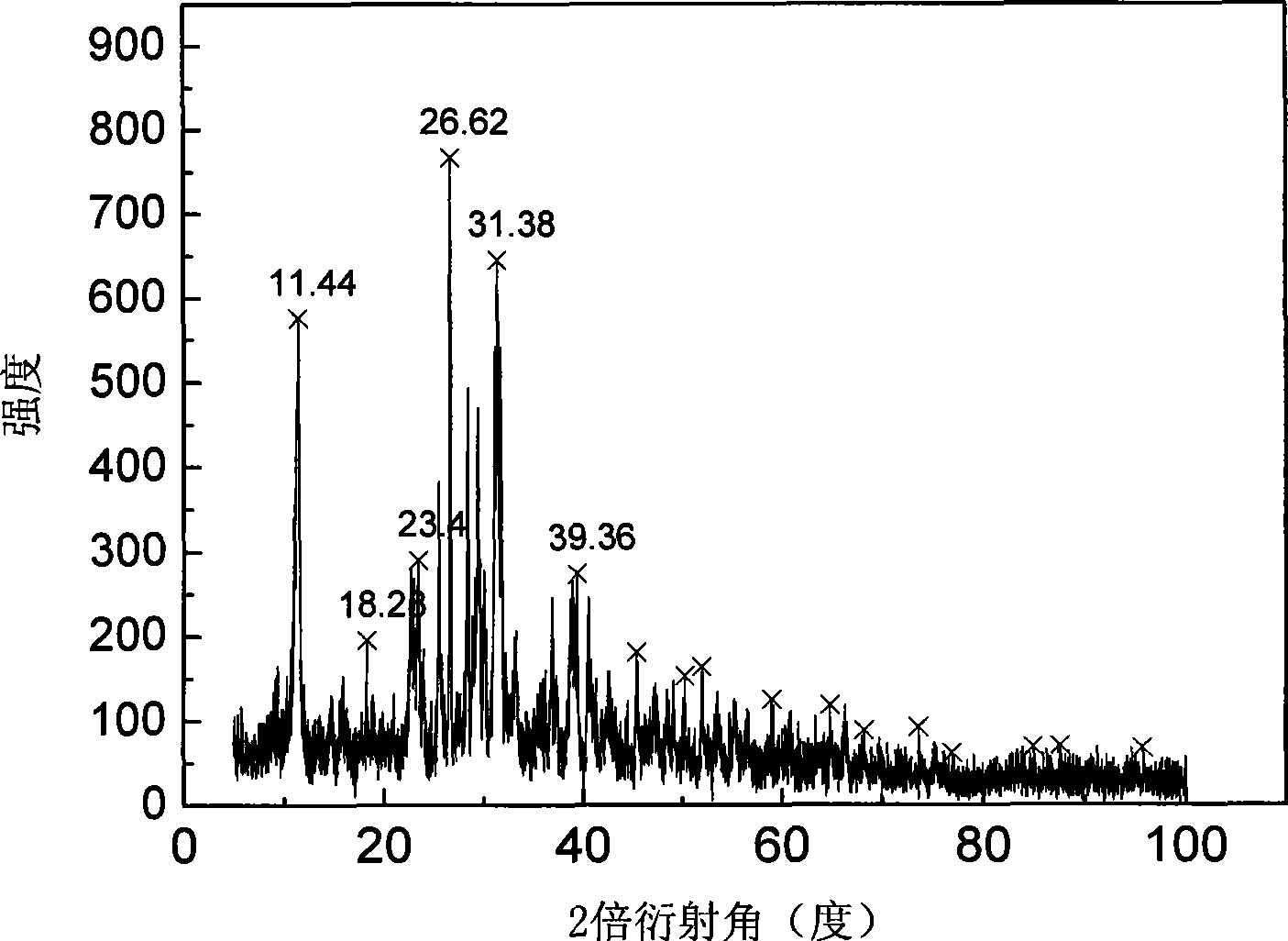

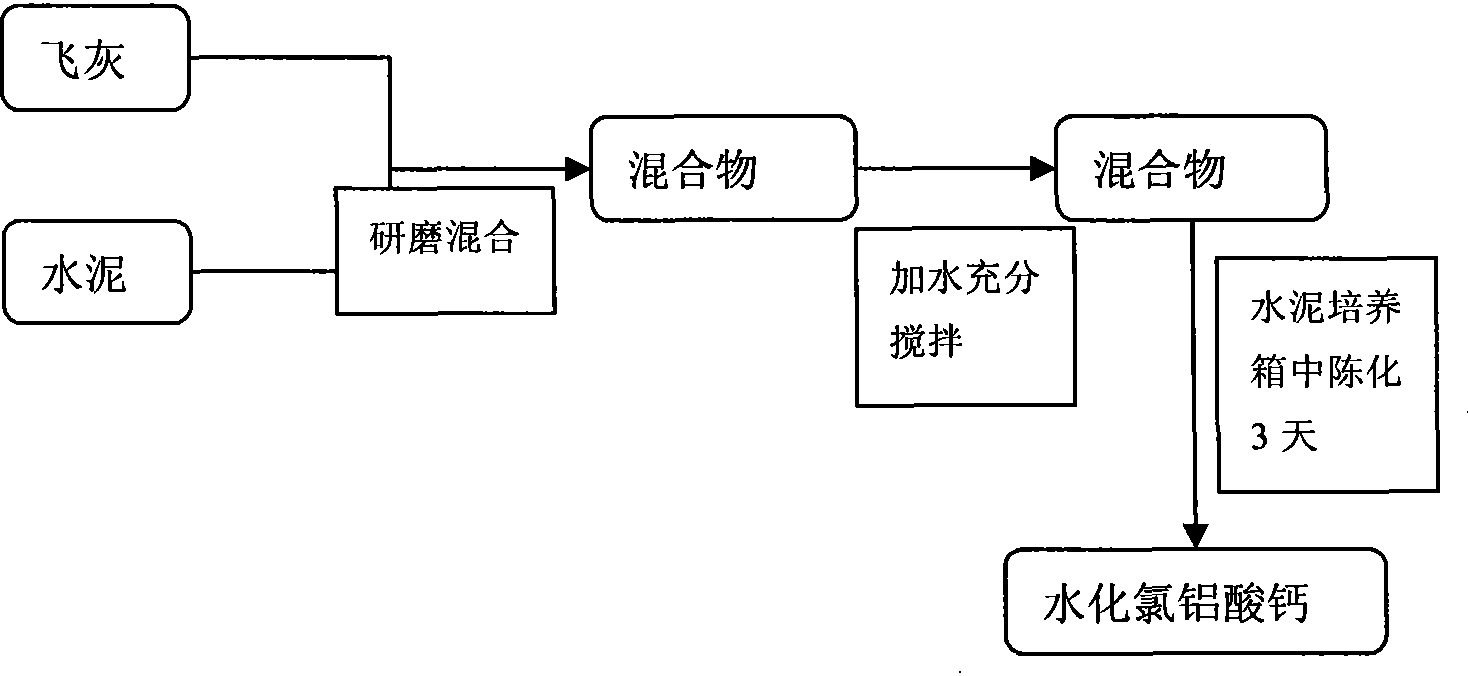

[0025] The specific synthetic route is attached to the manual figure 2 shown. Take 70g of municipal waste incineration fly ash. The municipal waste incineration fly ash is rich in calcium and soluble chlorine and has high alkalinity. Mix and stir the municipal waste incineration fly ash and deionized water at a mass ratio of 1:20 After equilibrium, the pH range of the solution is 10.5-11.5, and the chlorine is 0.16-0.2mol / L; then take 30g of CA50 aluminate cement. Blend, grind and pass through an 80-mesh sieve. After grinding and mixing evenly, add 33ml of deionized water to stir well and mix well. After mixing, put it into a cement incubator and cultivate it under the conditions of 20°C and 97% humidity for 3 days, then dry and grind at 65°C. Microparticles mainly composed of calcium chloroaluminate hydrate are obtained, and the chemical formula of the compound is 3CaO·Al 2 o 3 ·CaCl 2 10H 2 O. Its XRD analysis pattern is as follows figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com