Biological charcoal material for removing iodate in water and preparation method thereof

A biochar and water removal technology, applied in biofuels, water pollutants, chemical instruments and methods, etc., can solve the problems that iodate cannot be recycled and reused, resources are wasted, and the price is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

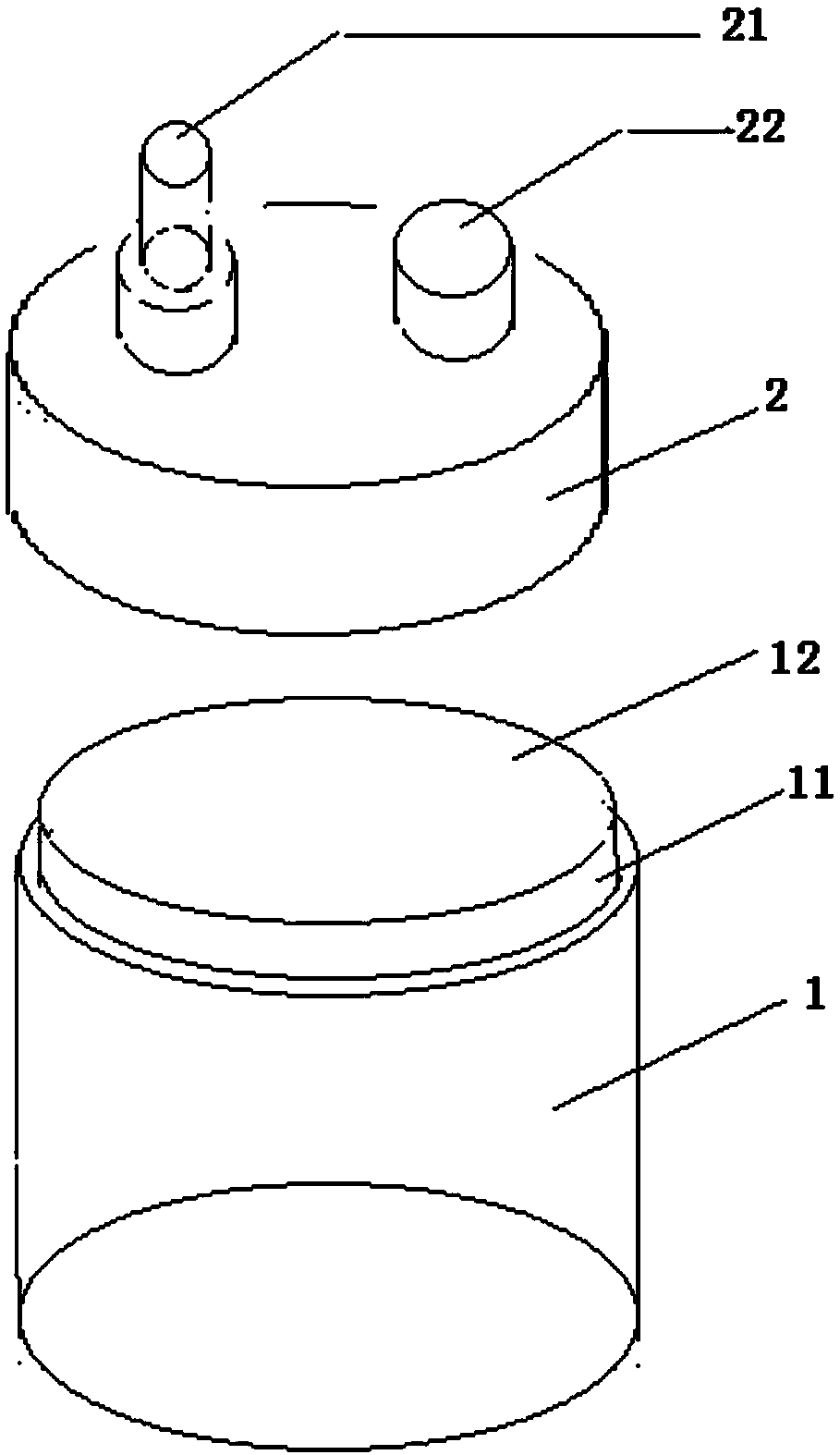

preparation example Construction

[0118] (3) The equipment for preparing biochar of the present invention is simple and beneficial to popularization; and it is not necessary to continuously feed nitrogen, which saves costs;

[0119] (4) The biochar of the present invention can be applied to remove iodate ions in wastewater, and the removal efficiency can reach more than 90%, and the removal efficiency is high;

[0120] (5) The method for removing iodate ions with biochar of the present invention can reclaim iodate and some biochar materials, broaden the selection range of adsorbents in the biological treatment process of wastewater purification, realize resource utilization of waste, and realize social benefits and economic benefits.

Embodiment 1

[0124] Crush corn stalks into powder;

[0125] Add 100g of corn stalk powder into the reactor of the carbonization equipment, and pass through the reactor to replace the reactor with nitrogen for 10-15 minutes, then heat at a rate of 6.5°C / min, the temperature rises from room temperature to 200°C, and keeps at 200°C for 60 minutes , and then continue heating at a heating rate of 3.5°C / min to 400°C and hold for 2 hours; then continue to heat up at a rate of 9.5°C / min to 500°C and hold for 2 hours, then continue to heat up at a rate of 9.5 °C / min, raise the temperature to 600 °C, and keep it warm for 2 hours; cool down to room temperature, open the reaction kettle, and obtain the generated carbonized powder;

[0126] Wash the above-mentioned carbonized powder with 300 mL of 0.1 mol / L hydrochloric acid, stir and wash for 3 hours, then filter, wash the filter cake with deionized water until neutral, and dry at 70°C for 24 hours to obtain biochar, with a mass of 30.0539 g; Denote ...

Embodiment 2

[0128] Crush corn stalks into powder;

[0129] Add 100g of corn stalk powder into the reactor of the carbonization equipment, and pass through the reactor to replace the reactor with nitrogen for 10-15 minutes, then heat at a rate of 6.5°C / min, the temperature rises from room temperature to 200°C, and keeps at 200°C for 60 minutes , and then continue to heat, the heating rate is 3.5 ° C / min, the temperature is raised to 400 ° C, and kept for 6 hours; when it is lowered to room temperature, the reaction kettle is opened to obtain the generated carbonized powder;

[0130] Wash the carbonized powder with 300mL of 0.1mol / L hydrochloric acid, stir and wash for 3h, then filter, wash the filter cake with deionized water until neutral, and dry at 70°C for 24h to obtain biochar with a mass of 35.2826g; for BC-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com