High-concentration landfill leachate membrane concentrated solution treatment process and application thereof

A landfill leachate, high-concentration technology, used in filtration treatment, polluted groundwater/leachate treatment, water/sewage treatment, etc., can solve problems such as high operating costs, difficult conditions to control, secondary pollution, etc. Filtration effect, low cost, and fouling mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

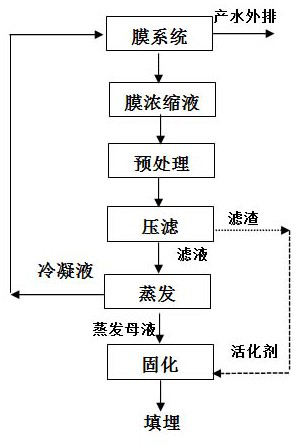

Image

Examples

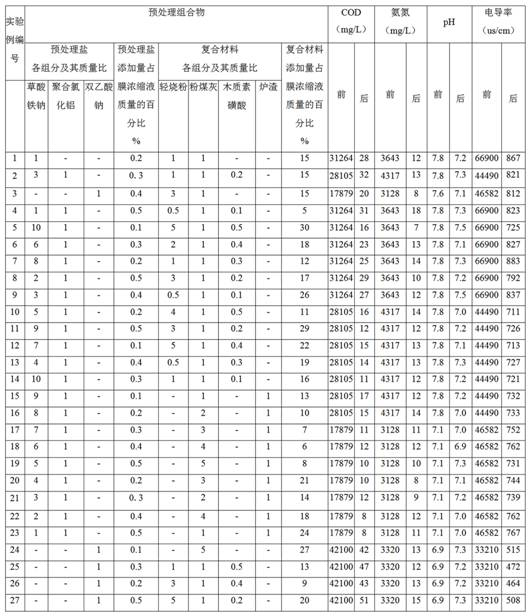

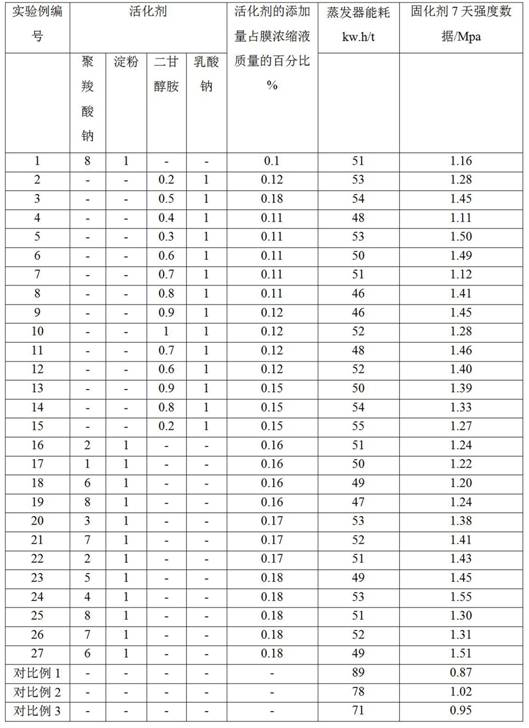

experiment example 1

[0162] A process for treating high-concentration landfill leachate membrane concentrate, the steps of which are as follows:

[0163] (1) Pretreatment: 1000kg of membrane concentrate produced by the leachate passing through the reverse osmosis membrane system, first add 2kg of sodium ferric oxalate and stir for 30 minutes, then add 150kg of lightly burned powder and fly ash (mass ratio of lightly burned powder to fly ash 1:1), continue stirring for 30 minutes;

[0164] (2) Pressure filtration: the concentrated liquid after stirring enters the pressure filtration system to obtain the filtrate and filter residue with a mass fraction of 80%, the filtrate enters the collection tank, and the filter residue is stored for later use;

[0165] (3) Evaporation: The filtrate enters the evaporation system from the collection tank for evaporation and concentration. After being concentrated 9 times, the evaporated mother liquor enters the solidification system, and the condensate returns to ...

experiment example 2

[0172] A process for treating high-concentration landfill leachate membrane concentrate, the steps of which are as follows:

[0173] (1) Pretreatment: 1000kg of membrane concentrate produced by the leachate passing through the reverse osmosis membrane system, first add 3kg of sodium ferric oxalate and polyaluminum chloride (the mass ratio of sodium ferric oxalate to polyaluminum chloride is 3:1) and stir for 30 minutes, Then add 150kg of lightly burned powder, fly ash, and lignosulfonic acid (mass ratio of lightly burned powder: fly ash: lignosulfonic acid is 1:1:0.2), and continue stirring for 50 minutes;

[0174] (2) Pressure filtration: The concentrated liquid after stirring enters the pressure filtration system to obtain the filtrate and filter residue with a mass fraction of 82%, the filtrate enters the collection tank, and the filter residue is stored for later use;

[0175] (3) Evaporation: The filtrate enters the evaporation system from the collection tank for evaporat...

experiment example 3

[0184] A process for treating high-concentration landfill leachate membrane concentrate, the steps of which are as follows:

[0185] (1) Pretreatment: 1000kg of membrane concentrate produced by the leachate through the reverse osmosis membrane system, first add 4kg of sodium diacetate and stir for 40min, then add 180kg of fly ash and slag (the mass ratio of fly ash: slag is 3:1 ), continue stirring for 60min;

[0186] (2) Pressure filtration: the concentrated liquid after stirring enters the pressure filtration system to obtain filtrate and filter residue with a mass fraction of 85%, the filtrate enters the collection tank, and the filter residue is stored for later use;

[0187] (3) Evaporation: The filtrate enters the evaporation system from the collection tank for evaporation and concentration. After 11 times of concentration, the evaporated mother liquor enters the solidification system, and the condensate returns to the membrane treatment system, and is discharged after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com