Sandwich type long nozzle sealing piece and manufacturing method thereof

A sandwich-type, long nozzle technology, which is applied to casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor corrosion resistance of nozzle gaskets, achieve excellent corrosion resistance, easy disassembly, and improve corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A sandwich type shroud seal and a preparation method thereof. The preparation method described in this embodiment is:

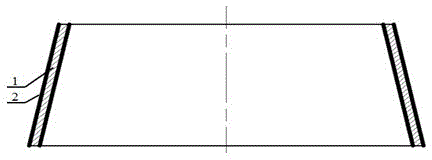

[0022] Using 15~25wt% sintered mullite and 75~85wt% platy corundum as raw materials, plus 10~20wt% water glass and 15~20wt% composite binder of the raw materials, mix evenly, cast and form, after pouring The green body 1 is in the shape of a bell mouth and is naturally dried; then graphite paper 2 is pasted on the inner and outer surfaces of the dried green body 1 to obtain a sandwich-type shroud seal.

[0023] The composite binder described in this embodiment is a mixed solution of resin and alcohol, and the mass ratio of resin to alcohol is 1:(2~1); the resin is phenolic resin.

Embodiment 2

[0025] A sandwich type shroud seal and a preparation method thereof. The preparation method described in this embodiment is:

[0026] 25~35wt% fused mullite and 65~75wt% white corundum are used as raw materials, plus 20~30wt% water glass and 20~25wt% composite binder of the raw materials, mixed evenly, poured and molded, after pouring The green body 1 is in the shape of a bell mouth and is naturally dried; then graphite paper 2 is pasted on the inner and outer surfaces of the dried green body 1 to obtain a sandwich-type shroud seal.

[0027] The composite binder described in this embodiment is a mixed solution of resin and alcohol, and the mass ratio of resin to alcohol is 1:(3~2); the resin is epoxy resin.

Embodiment 3

[0029] A sandwich type shroud seal and a preparation method thereof. The preparation method described in this embodiment is:

[0030] Use 35-455wt% sintered mullite and 55-65wt% brown corundum as raw materials, add 30-40wt% water glass and 25-30wt% composite binder, mix evenly, cast and form, and cast The green body 1 is in the shape of a bell mouth and is naturally dried; then graphite paper 2 is pasted on the inner and outer surfaces of the dried green body 1 to obtain a sandwich-type shroud seal.

[0031] The composite binder described in this embodiment is a mixed solution of resin and alcohol, and the mass ratio of resin to alcohol is 1:(3~4); the resin is furan resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com