Crucible for melting high-purity aluminum and preparation method thereof

A crucible and high-purity technology, applied in crucible furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of inability to apply high-purity alumina to high-efficiency continuous production, and achieve excellent non-wetting properties, high strength, and low expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

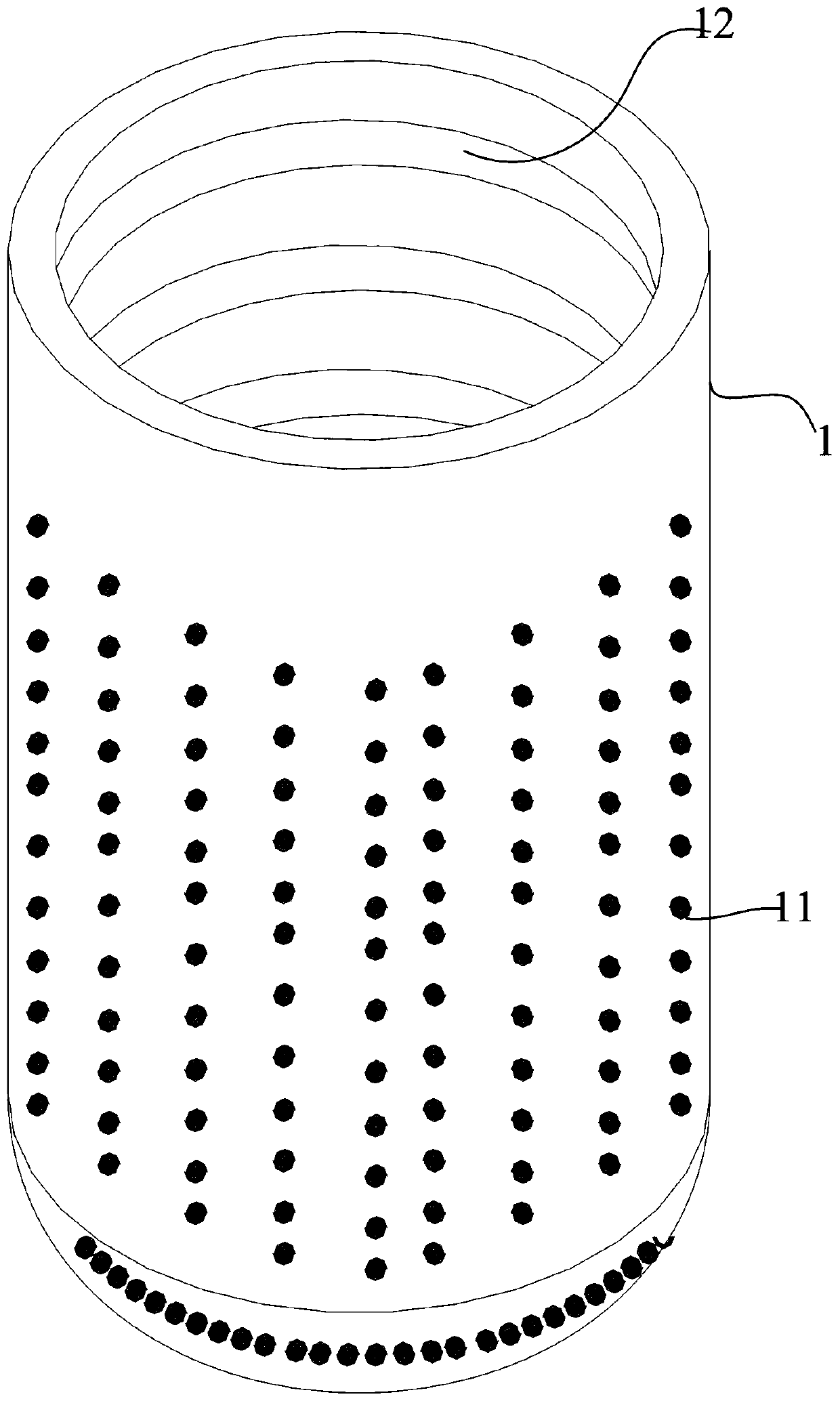

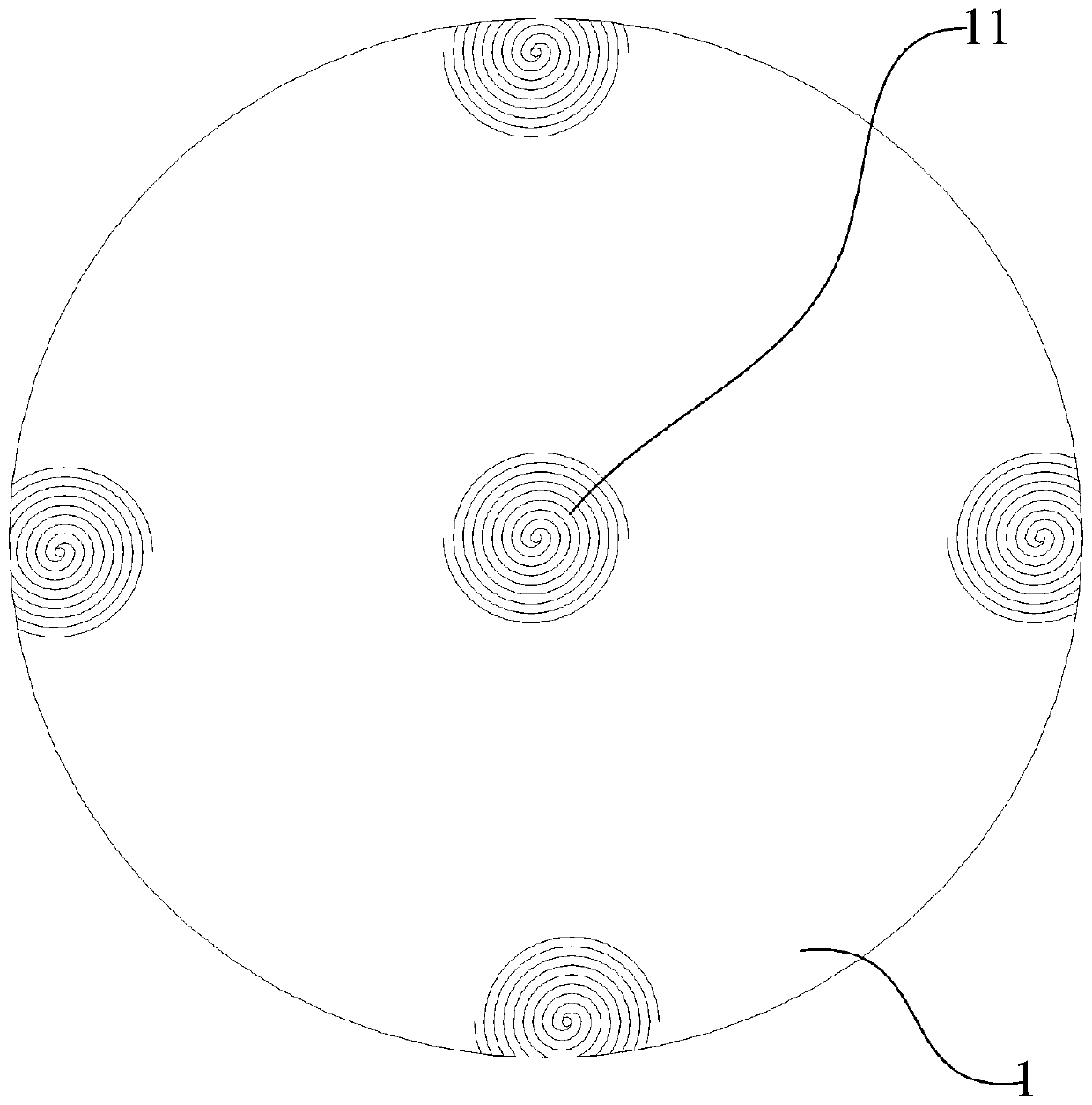

[0023] Embodiment 1, this embodiment provides a crucible for melting high-purity aluminum and its preparation method

[0024] This embodiment aims to solve the problem that most existing crucibles contain iron oxide, silicon dioxide and other components, while graphite crucibles have poor oxidation resistance, which leads to the inability to produce high-purity alumina by continuous hydrolysis.

[0025] For this reason, the crucible provided in this embodiment includes the following active ingredients in parts by weight: 65 parts of aluminum oxide fine powder with a purity of 99.999%, 10 parts of metallic aluminum fine powder with a purity ≥ 99.995%, 5 parts of aluminum sol, 5 parts of distilled water, wherein the aluminum sol is the aluminum sol formed in the process of producing high-purity alumina by the hydrolysis method, and the high-purity aluminum oxide fine powder used in this embodiment is also the high-purity alumina obtained by the hydrolysis method Of course, high-...

Embodiment 2

[0029] Embodiment 2, this embodiment provides a crucible for melting high-purity aluminum and its preparation method

[0030] This embodiment aims to solve the problem that most existing crucibles contain iron oxide, silicon dioxide and other components, while graphite crucibles have poor oxidation resistance, which leads to the inability to produce high-purity alumina by continuous hydrolysis.

[0031] For this reason, the crucible provided in this embodiment includes the following active ingredients in parts by weight: 85 parts of aluminum oxide fine powder with a purity of 99.999%, 25 parts of metallic aluminum fine powder with a purity of 99.995%, 10 parts of aluminum sol, 10 parts of distilled water, wherein the aluminum sol is the aluminum sol formed in the process of producing high-purity alumina by the hydrolysis method, and of course, the high-purity aluminum oxide fine powder used in this embodiment is also obtained by the hydrolysis method. Alumina, of course, can a...

Embodiment 3

[0035] Embodiment 3, this embodiment provides a crucible for melting high-purity aluminum and its preparation method

[0036] This embodiment aims to solve the problem that most existing crucibles contain iron oxide, silicon dioxide and other components, while graphite crucibles have poor oxidation resistance, which leads to the inability to produce high-purity alumina by continuous continuous hydrolysis.

[0037] Therefore, the crucible provided in this embodiment includes the following active ingredients in parts by weight: 5 parts of aluminum oxide fine powder with a purity of 99.999%, 17.5 parts of metallic aluminum fine powder with a purity of 99.995%, 7.5 parts of aluminum sol, 7.5 parts of distilled water, wherein the aluminum sol is the aluminum sol formed in the process of producing high-purity alumina by the hydrolysis method, and certainly, the high-purity aluminum oxide fine powder used in this embodiment is also obtained by the hydrolysis method. Alumina, of cours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com