Lithium battery negative electrode material with layered structure and preparation method thereof

A layered structure and negative electrode material technology, applied in battery electrodes, lithium batteries, structural parts, etc., can solve the problems of large volume expansion, etc., and achieve the effects of improving heat resistance, improving heat resistance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

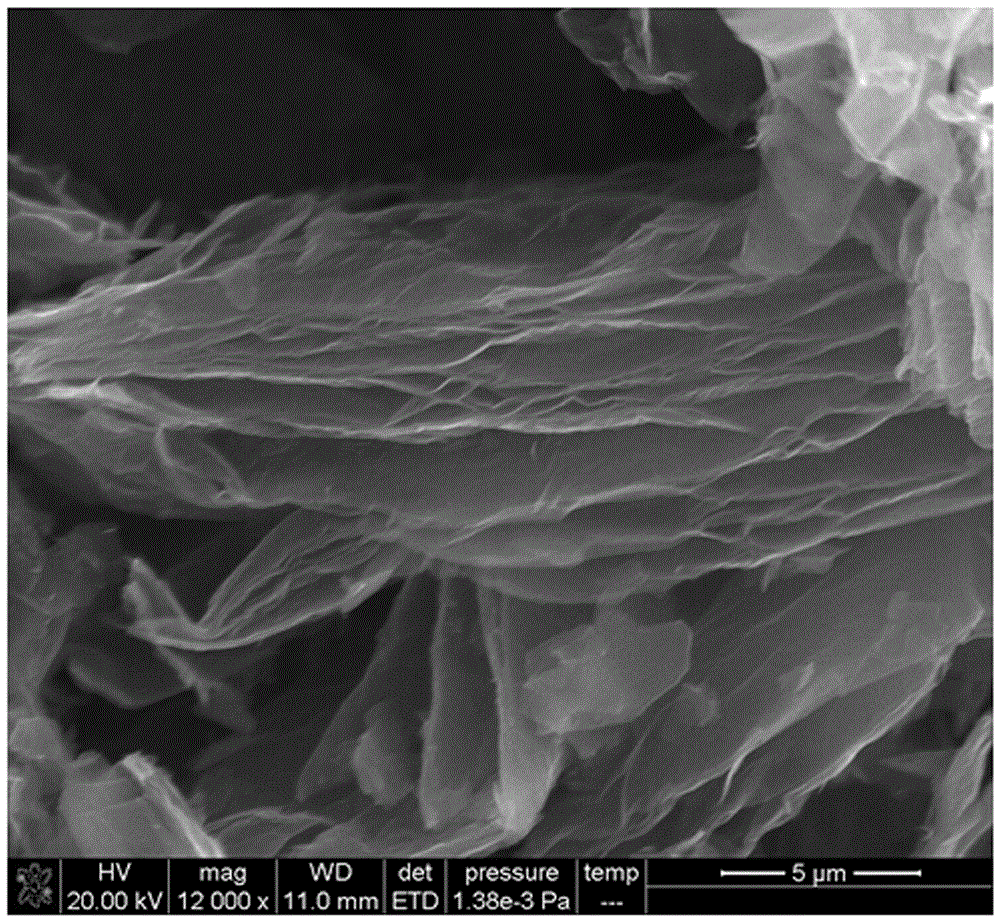

[0034]Self-made layered graphene: use flake graphite as a carbon source, exfoliate flake graphite into graphene and add functional groups to such graphene to obtain the desired layered graphene. According to Hummer's method, add flake graphite to the mixture of concentrated sulfuric acid, potassium permanganate and sodium nitrate and mix well. Put the three-neck flask containing the mixed solution in an ice bath and stir for 1h~3h, then stir for 1h~3h at 30°C~50°C, and finally add 10%~20% of the prepared mass fraction to the mixed solution % hydrogen peroxide, stirred and reacted at 90°C~100°C for 4h~6h. This treatment mainly increases some oxygen-containing groups such as -OH, -C=O. See the SEM photos of self-made layered graphene figure 1 . from the figure 1 It can be seen that the self-made layered graphene has an obvious sheet structure, and the surface area of graphene increases, and substances can be deposited into the gaps of the sheets.

Embodiment 2

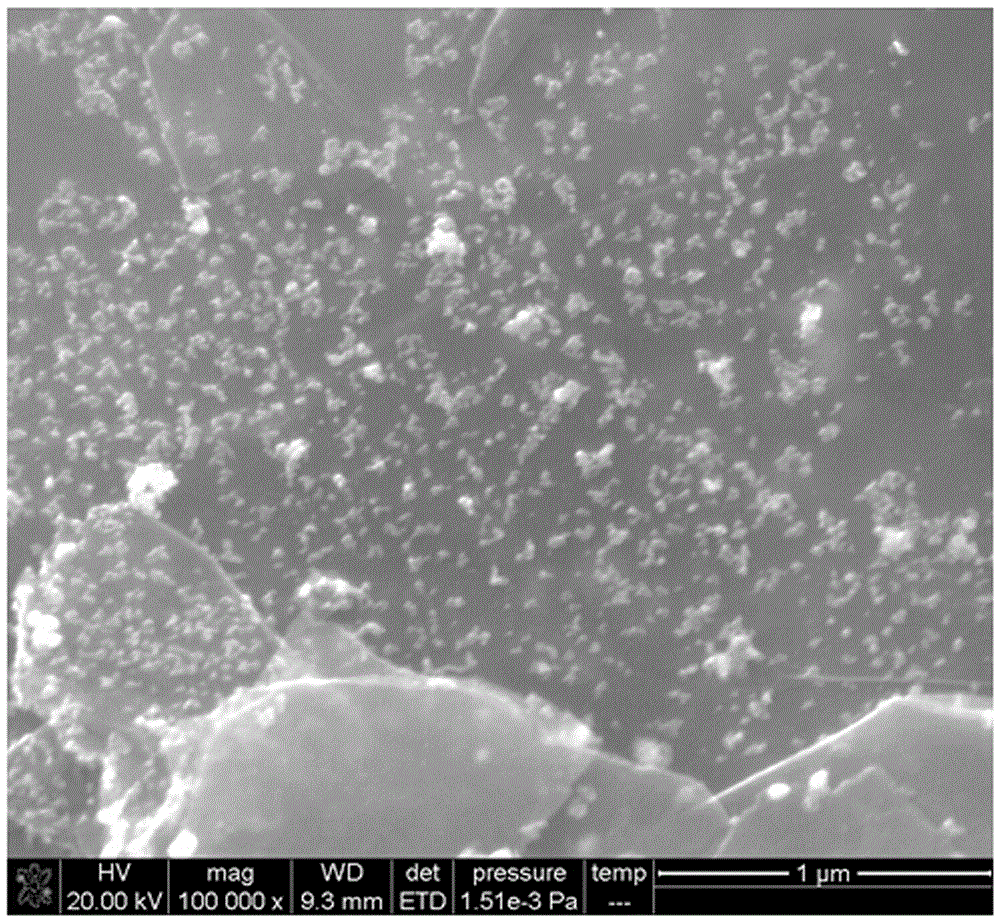

[0036] Weigh 5g of self-made layered graphene and place it in 150ml of 1% palladium chloride solution, heat to 55°C and stir magnetically for 30min, then add 15g / L 30ml of sodium hypophosphite, stir magnetically for 30min, wash and dry dry to obtain activated graphene. 4g of activated graphene was added to 12g / L 300ml nickel sulfate plating solution, ultrasonically reacted at 80°C for 1 hour, washed and dried to obtain a nickel-plated sample. The SEM photograph of the sample is shown in figure 2 . from the figure 2 It is obvious that flocculent particles are deposited on the graphene.

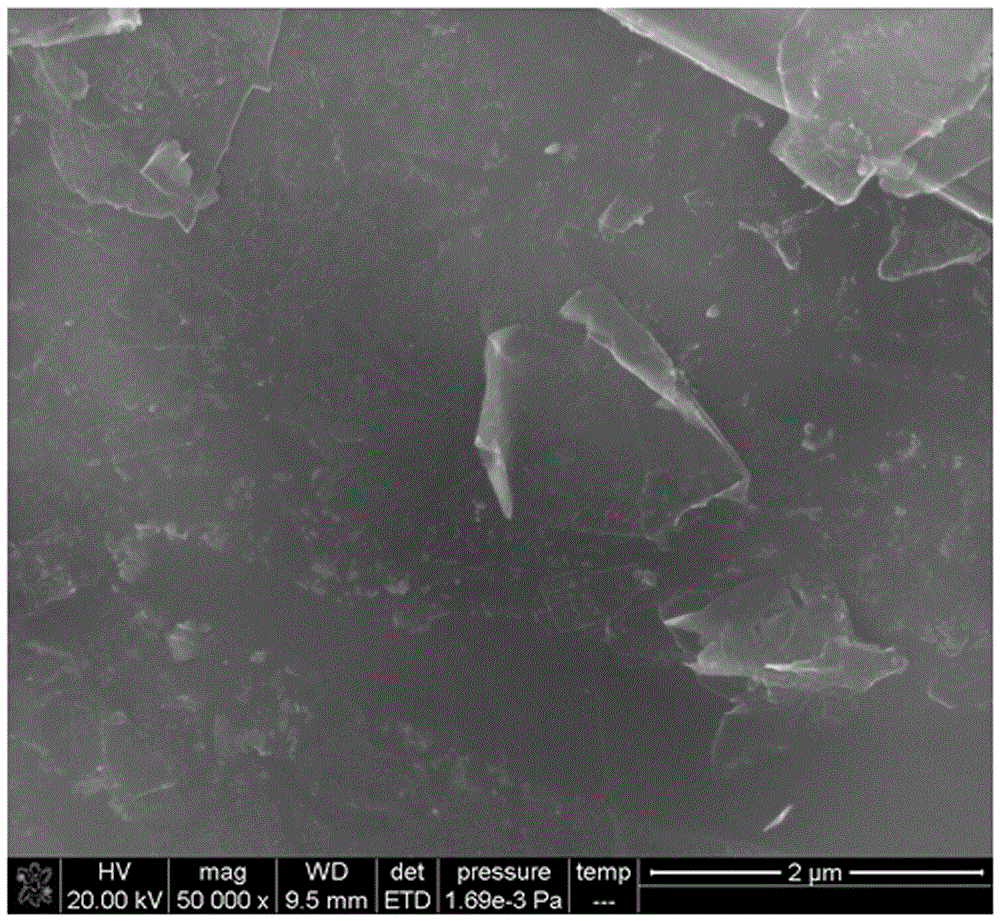

[0037] Weigh 3g of nickel plating sample and add it to 15g / L 300ml stannous chloride plating solution, ultrasonically react at 80°C for 1 hour, wash and dry to obtain Sn-Ni-graphene composite material. The SEM photograph of the material is shown in Figure 5 . from Figure 5 It is obvious that after electroless nickel plating and electroless tin plating, tiny flocculent particles exist...

Embodiment 3

[0047] Weigh 5g of self-made layered graphene and place it in 150ml of 1% palladium chloride solution, heat to 70°C and stir magnetically for 30min, then add 15g / L 30ml of sodium hypophosphite, stir magnetically for 30min, wash and dry , to obtain activated graphene. 4g of activated graphene was added to 12g / L 300ml nickel sulfate plating solution, ultrasonically reacted at 80°C for 1 hour, washed and dried to obtain a nickel-plated sample. Weigh 3g of nickel-plated sample and add it to 15g / L 300ml stannous chloride plating solution, ultrasonically react at 80°C for 1 hour, wash and dry to obtain Sn-Ni-graphene composite material. Put 1g of Sn-Ni-graphene composite material in a burning boat and put it into a quartz tube furnace. Ar was introduced as a protective gas, the gas flow rate was 200ml / min, the temperature was raised from room temperature to 600 °C at a rate of 3 °C / min, kept for 2 hours, and then naturally cooled to room temperature to obtain a calcined product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com