Inorganic superhydrophobic anti-icing structure with multistage pore structure and preparation method and application thereof

A super-hydrophobic, ice-structured technology, applied in nanotechnology for materials and surface science, metal material coating technology, nanotechnology, etc., can solve the problems of low surface modification, pollute the environment, affect the surface of materials, etc., and achieve excellent Effect of anti-icing properties, good non-wetting and water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

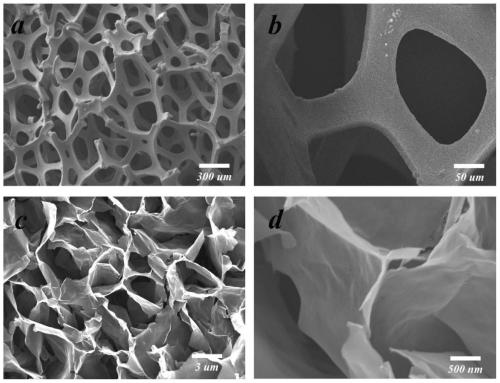

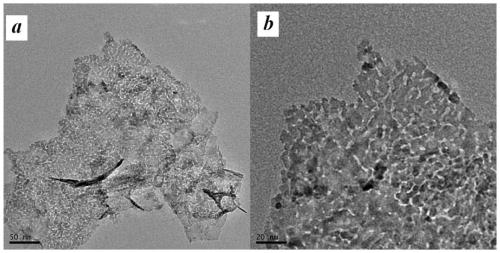

[0062] A method for preparing an inorganic superhydrophobic anti-icing structure with a hierarchical porous structure, comprising the following steps:

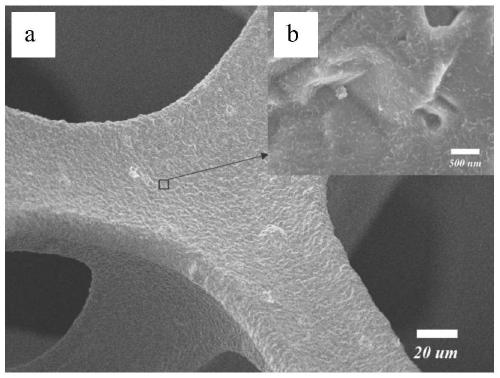

[0063] 1) Prepare the three-dimensional porous metal, the three-dimensional porous metal is nickel foam, and pretreat the three-dimensional porous metal: at room temperature 20-25°C, put the three-dimensional porous metal into hydrochloric acid (Sinopharm, AR), ethanol and The oxygen-dissolved deionized water was sonicated for 20 minutes each, wherein the concentration of hydrochloric acid was 3 mol / L, and the temperatures of the hydrochloric acid, ethanol and deionized water were respectively 50°C during sonication (realized by a water bath). The role of foam nickel (surface) pretreatment is: the hydrochloric acid of dissolved oxygen causes the original inert nickel oxide on the surface of foam nickel to be washed away, and the exposed highly active nickel is rapidly oxidized to form nickel oxide, and then soaked in deionized ...

Embodiment 2

[0069] A method for preparing an inorganic superhydrophobic anti-icing structure with a hierarchical porous structure, comprising the following steps:

[0070] 1) Pretreatment of the three-dimensional porous metal: at a room temperature of 20-25°C, put the three-dimensional porous metal into hydrochloric acid with dissolved oxygen (Sinopharm, AR), ethanol, and deionized water with dissolved oxygen for 20 minutes respectively, among which, The concentration of hydrochloric acid is 2 mol / L, and the temperatures of hydrochloric acid, ethanol and deionization are respectively 60° C. (realized by water bath) during ultrasonication.

[0071] Clean the three-dimensional porous metal after pretreatment: soak the three-dimensional porous metal in deionized water with dissolved oxygen for 8 hours.

[0072] After cleaning, dry at 60°C for 2 hours in a drying oven (Boxun, DZF-6020) with a vacuum degree of 0.08MPa, wherein the three-dimensional porous metal is nickel foam;

[0073] 2) Imm...

Embodiment 3

[0076] A method for preparing an inorganic superhydrophobic anti-icing structure with a hierarchical porous structure, comprising the following steps:

[0077] 1) Pretreatment of the three-dimensional porous metal: at a room temperature of 20-25°C, put the three-dimensional porous metal into hydrochloric acid with dissolved oxygen (Sinopharm, AR), ethanol, and deionized water with dissolved oxygen for 20 minutes respectively, among which, The concentration of hydrochloric acid is 1 mol / L, and the temperatures of hydrochloric acid, ethanol and deionization are respectively 40° C. (realized by water bath) during ultrasonication.

[0078] Clean the three-dimensional porous metal after pretreatment: soak the three-dimensional porous metal in deionized water with dissolved oxygen for 10 hours.

[0079] After cleaning, dry at 60°C for 2 hours in a drying oven (Boxun, DZF-6020) with a vacuum degree of 0.08MPa, wherein the three-dimensional porous metal is nickel foam;

[0080] 2) Im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com