a liquid pressure gauge

A liquid manometer and dispersion technology, applied in the field of liquid manometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

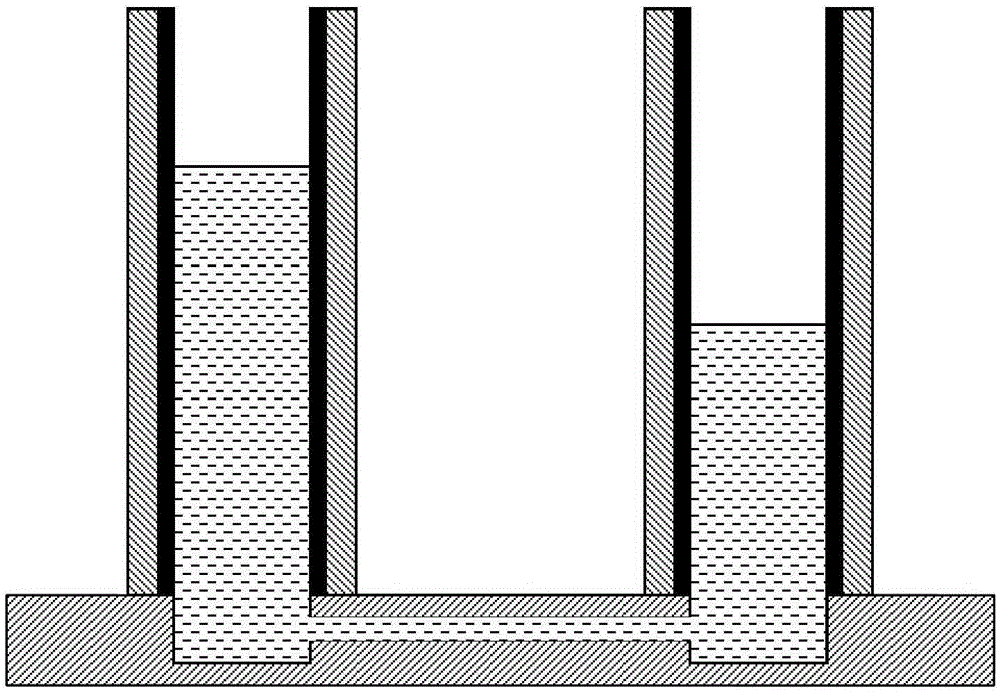

[0026] The utility model relates to a liquid pressure gauge. The inner tube is a U-shaped tube. The two vertical tubes of the U-shaped tube are made of stainless steel. The inner walls of the two stainless steel tubes are coated with a Teflon coating and cured at high temperature. The Teflon coating has the functions of hydrophobic and oleophobic, and the liquid medium such as water and oil in the pipe will not hang on the pipe wall.

[0027] The Teflon material used is polytetrafluoroethylene (PTFE) (commercially available)

[0028] The process of preparing the Teflon coating is as follows:

[0029] 1. First prepare the stainless steel tube for the liquid pressure gauge, remove the grease on the inner wall of the tube. The inner wall of the stainless steel tube was washed with acetone, and then heated to about 400° C. to completely volatilize the organic solvent.

[0030] 2. Use sandblasting to clean the inner wall of the pipe and make the surface rough. Specifically, 40-7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com