A kind of preparation method of yttrium oxide microspheres used in titanium alloy vacuum brazing choke agent

A technology of yttrium oxide and titanium alloy, which is applied in the field of welding technology and material preparation, can solve the problems such as the decrease of fluidity of the blocking agent, affecting the normal use, affecting the processing efficiency of brazing, and achieving the decrease of surface tension, the improvement of welding resistance, The effect of good solder mask effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

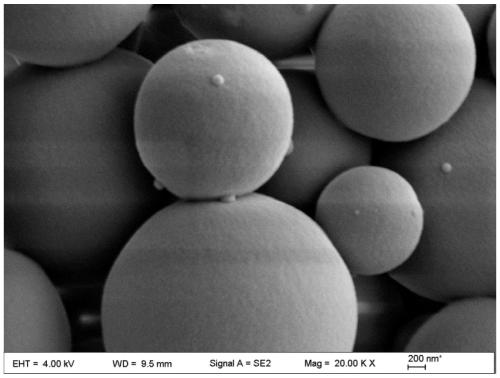

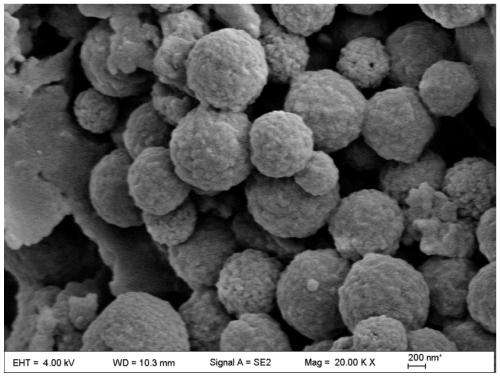

[0027] A method for preparing surface roughened yttrium oxide microspheres for titanium alloy vacuum brazing flow inhibitors includes the following steps:

[0028] (1) Add yttrium nitrate to deionized water and stir for 10 minutes to obtain an aqueous solution of yttrium nitrate. The mass fraction of the yttrium nitrate solution is 5%. Sodium oleate is added to deionized water and stirred for 10 minutes to fully dissolve the sodium oleate solution. , The mass fraction of the sodium oleate aqueous solution is 5%, while stirring, add the yttrium nitrate aqueous solution dropwise to the sodium oleate aqueous solution. After the dropwise addition is completed, the temperature is raised to 60°C, and the stirring is continued for 30 minutes. After full reaction, the precipitate is filtered out. The filtered precipitate was washed 5 times with deionized water, and after drying, the yttrium oleate complex was obtained. The molar ratio of yttrium nitrate to sodium oleate is controlled at ...

Embodiment 2

[0035] A method for preparing surface roughened yttrium oxide microspheres for titanium alloy vacuum brazing flow inhibitors includes the following steps:

[0036] (1) Add yttrium nitrate to deionized water and stir for 30 minutes to obtain an aqueous solution of yttrium nitrate. The mass fraction of yttrium nitrate aqueous solution is 15%. Sodium oleate is added to deionized water and stirred for 30 minutes to fully dissolve the sodium oleate solution. , The mass fraction of the sodium oleate aqueous solution is 15%, while stirring, add the yttrium nitrate aqueous solution dropwise to the sodium oleate aqueous solution. After the dropwise addition is completed, the temperature is raised to 80°C and the stirring is continued for 1 hour. After full reaction, the precipitate is filtered out. The filtered precipitate was washed 5 times with deionized water, and after drying, the yttrium oleate complex was obtained. The molar ratio of yttrium nitrate to sodium oleate is controlled at...

Embodiment 3

[0043] A method for preparing surface roughened yttrium oxide microspheres for titanium alloy vacuum brazing flow inhibitors includes the following steps:

[0044] (1) Add yttrium nitrate to deionized water and stir for 20 minutes to obtain an aqueous solution of yttrium nitrate. The mass fraction of the yttrium nitrate solution is 10%. Sodium oleate is added to deionized water and stirred for 20 minutes to fully dissolve the sodium oleate solution. , The mass fraction of the sodium oleate aqueous solution is 10%, while stirring, add the yttrium nitrate aqueous solution dropwise to the sodium oleate aqueous solution. After the dropwise addition is completed, the temperature is raised to 70°C, and the stirring is continued for 45 minutes. After full reaction, the precipitate is filtered out. The filtered precipitate was washed 5 times with deionized water, and after drying, the yttrium oleate complex was obtained. The molar ratio of yttrium nitrate to sodium oleate is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com