Zirconium mullite red brick and preparation technology thereof

A preparation process, the technology of zirconium molybdenum bricks, applied in the field of refractory materials, can solve the problems of short service life of bricks used in the transition zone, and achieve the effects of strong erosion resistance, lower temperature, and high thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

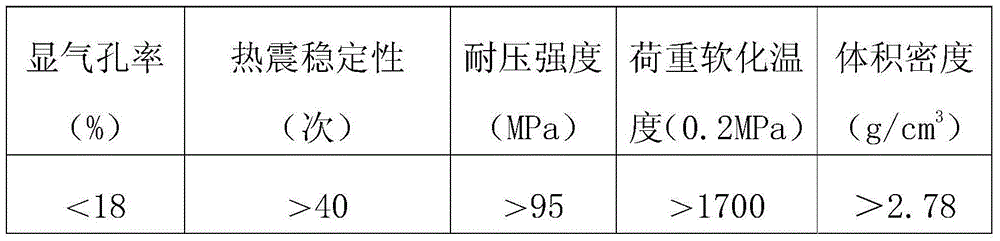

Embodiment 1

[0046] Zirconium red brick, including the following components, the weight percentage of each component is:

[0047] Super-grade high-bauxite clinker with a diameter greater than 3 mm and less than or equal to 5 mm: 5%;

[0048] Super-grade high-bauxite clinker with a diameter greater than 1 mm and less than or equal to 3 mm: 18%;

[0049] Sintered mullite with a diameter greater than 1 mm and less than or equal to 3 mm: 15%;

[0050] Synthetic mullite with a diameter greater than 0.1 mm and less than or equal to 1 mm: 10%, the synthetic mullite is Al 2 o 3High-temperature synthetic mullite with a content greater than or equal to 70%;

[0051] Synthetic mullite with a diameter of less than 0.1 mm: 7%, said synthetic mullite being Al 2 o 3 High-temperature synthetic mullite with a content greater than or equal to 70%;

[0052] Zirconium concentrate powder with a diameter greater than 0.1 mm and less than or equal to 1 mm and containing more than or equal to 65% zirconium:...

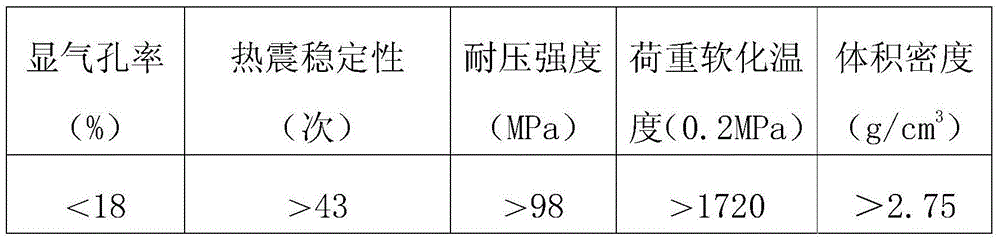

Embodiment 2

[0073] Zirconium red brick, including the following components, the weight percentage of each component is:

[0074] Super-grade high-bauxite clinker with a diameter greater than 3 mm and less than or equal to 5 mm: 8%;

[0075] Super-grade high-bauxite clinker with a diameter greater than 1 mm and less than or equal to 3 mm: 15%;

[0076] Sintered mullite with a diameter greater than 1 mm and less than or equal to 3 mm: 17%;

[0077] Synthetic mullite with a diameter greater than 0.1 mm and less than or equal to 1 mm: 10%, the synthetic mullite is Al 2 o 3 High-temperature synthetic mullite with a content greater than or equal to 70%;

[0078] Synthetic mullite with a diameter of less than 0.1 mm: 5%, said synthetic mullite being Al 2 o 3 High-temperature synthetic mullite with a content greater than or equal to 70%;

[0079] Zirconium concentrate powder with a diameter greater than 0.1 mm and less than or equal to 1 mm and containing more than or equal to 65% zirconium...

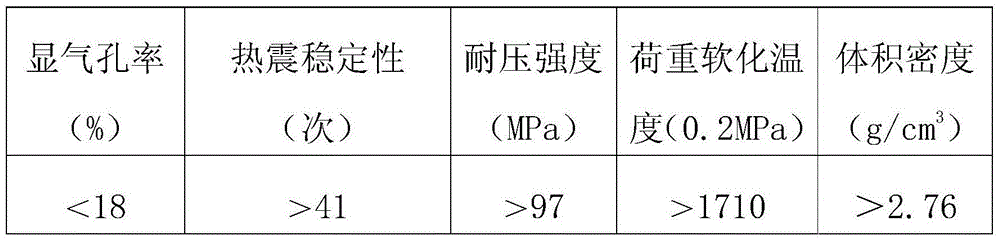

Embodiment 3

[0100] Zirconium red brick, including the following components, the weight percentage of each component is:

[0101] Super-grade high-bauxite clinker with a diameter greater than 3 mm and less than or equal to 5 mm: 10%;

[0102] Super-grade high-bauxite clinker with a diameter greater than 1 mm and less than or equal to 3 mm: 17%;

[0103] Sintered mullite with a diameter greater than 1 mm and less than or equal to 3 mm: 20%;

[0104] Synthetic mullite with a diameter greater than 0.1 mm and less than or equal to 1 mm: 13%, and the synthetic mullite is Al 2 o 3 High-temperature synthetic mullite with a content greater than or equal to 70%;

[0105] Synthetic mullite with a diameter of less than 0.1 mm: 8%, said synthetic mullite being Al 2 o 3 High-temperature synthetic mullite with a content greater than or equal to 70%;

[0106] Zirconium concentrate powder with a diameter greater than 0.1 mm and less than or equal to 1 mm and containing more than or equal to 65% zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com