Method for preparing refractory shed plate

A shed board and refractory technology, applied in the field of refractory materials, can solve the problems of uneven structure, difficult adaptation, internal cracks, etc., and achieve the effects of high softening temperature under load, high production efficiency and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials and proportions of isostatic pressing cordierite slabs:

[0021] Coarse material with particle diameter d<0.5mm 40%

[0022] Powder with particle diameter d<0.044mm 60%

[0023] Coarse material and powder material are all cordierite.

[0024] Prepare as follows:

[0025] 1) The cordierite raw material is ground to a powder below 44um for use;

[0026] 2) Mixing of powder and coarse material with a particle size of 0.5-0mm;

[0027] 3) The uniformly mixed raw materials are added to the mold, and isostatically pressed at 150Mpa to form;

[0028] 4) Release the pressure, release the mold, and take out the adobe with a manipulator;

[0029] 5) Natural drying at room temperature for 24 hours;

[0030] 6) enter the shuttle kiln for firing, the firing temperature is 1390°C, and the firing holding time is 6 hours;

[0031] 7) After cooling, grinding is performed.

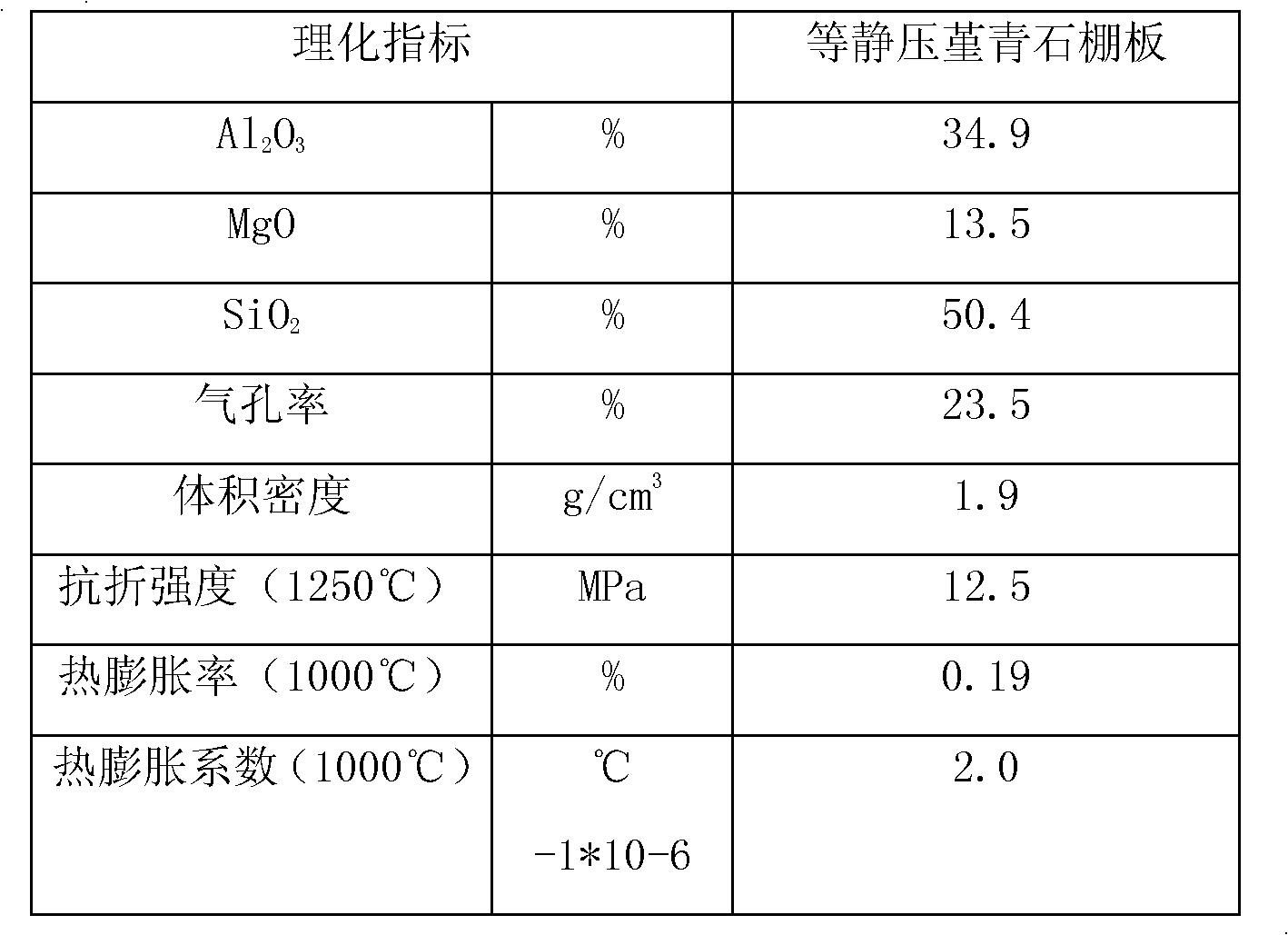

[0032] The physical and chemical indicators of the product are shown in Table 1.

[0033] T...

Embodiment 2

[0036] Cordierite-Morco shed board raw materials and their proportions:

[0037] Coarse material with particle diameter d<1mm 40%

[0038] Powder with particle diameter d<0.044mm 60%

[0039] The coarse material is Morco, 50% of cordierite is added to the powder, and 10% of α-alumina micropowder is added.

[0040] Prepare as follows:

[0041] 1) The cordierite raw material is ground to a powder below 44um for use;

[0042] 2) Mixing cordierite powder, α-alumina micropowder and Morco coarse material;

[0043] 3) The uniformly mixed raw materials are added to the mold, and isostatically pressurized at 180Mpa to form;

[0044] 4) Release the pressure, release the mold, and take out the adobe with a manipulator;

[0045] 5) Natural drying at room temperature for 24 hours;

[0046] 6) enter the shuttle kiln for firing, the firing temperature is 1420°C, and the firing holding time is 16 hours;

[0047] 7) After cooling, grinding is performed.

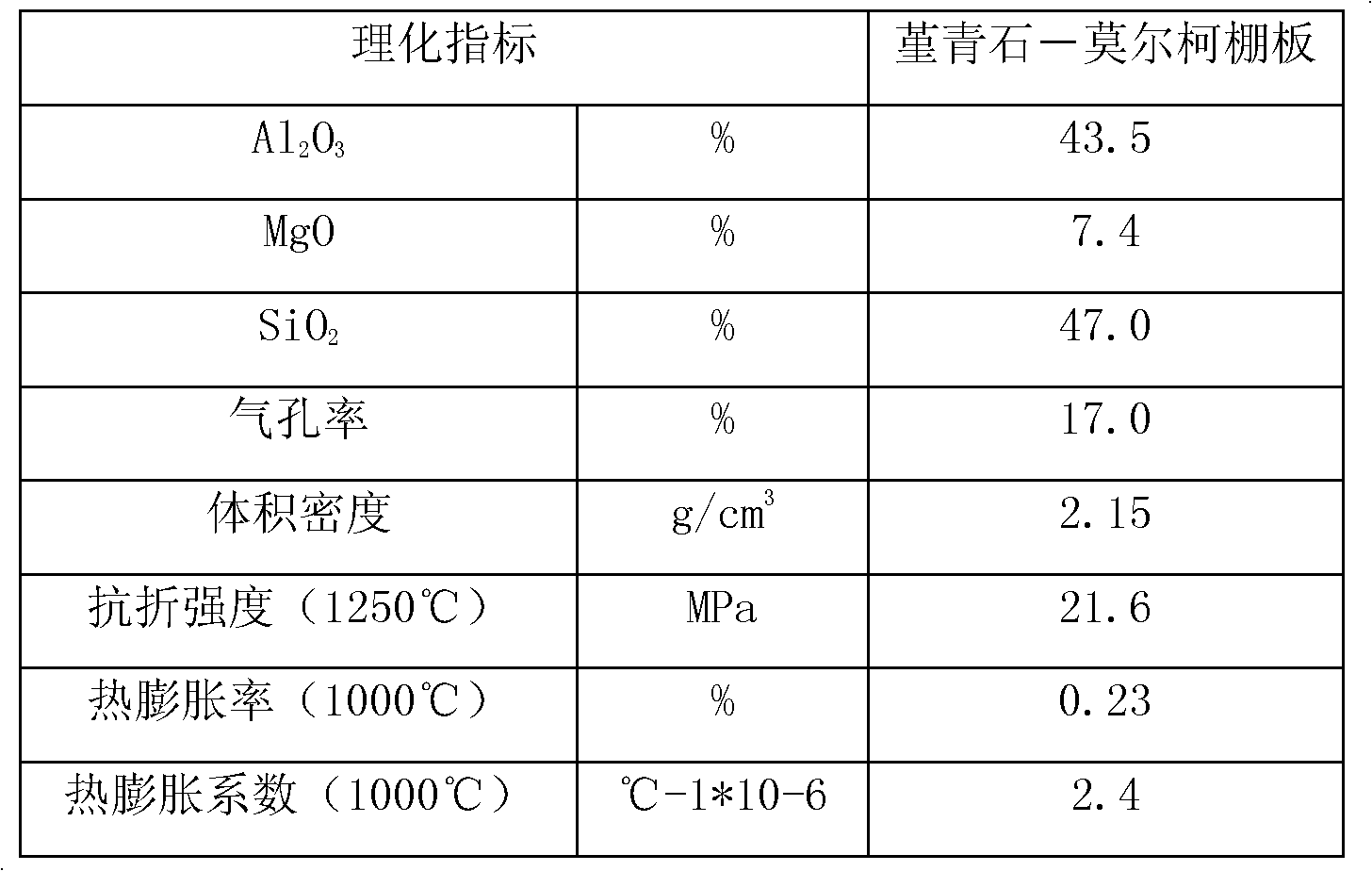

[0048] The physical and chemic...

Embodiment 3

[0052] Cordierite-mullite slab raw materials and their ratio:

[0053] Coarse material with particle diameter d<1mm 40%

[0054] Powder with particle diameter d<0.044mm 60%

[0055] The coarse material is mullite, and the powder material is cordierite.

[0056] Prepare as follows:

[0057] 1) The cordierite raw material is ground to a powder below 44um for use;

[0058] 2) Mixing powder and mullite coarse material;

[0059] 3) The uniformly mixed raw materials are added to the mold, and isostatically pressurized at 260Mpa to form;

[0060] 4) Release the pressure, release the mold, and take out the adobe with a manipulator;

[0061] 5) Natural drying at room temperature for 24 hours;

[0062] 6) enter the shuttle kiln for firing, the firing temperature is 1420°C, and the firing holding time is 16 hours;

[0063] 7) After cooling, grinding is performed.

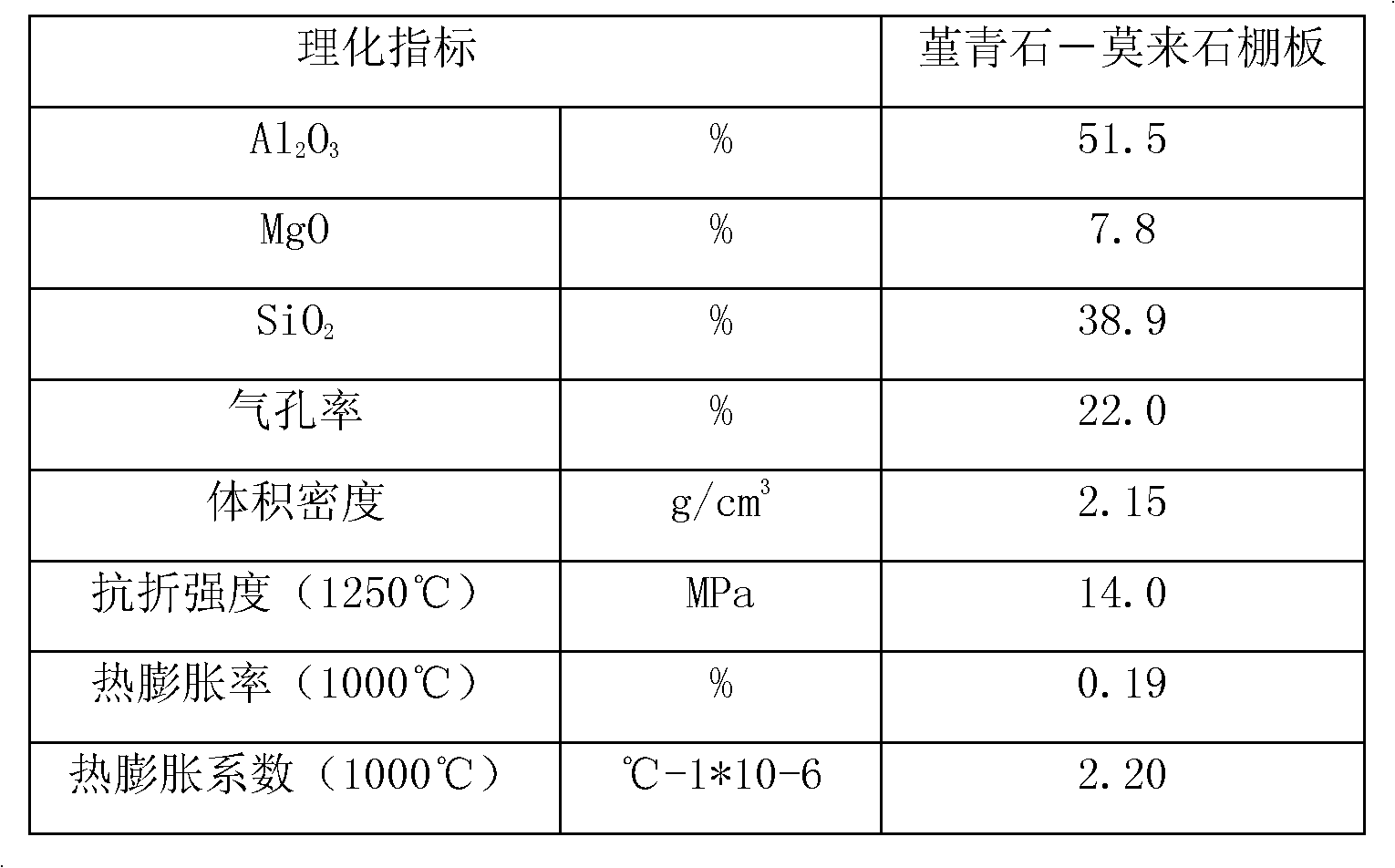

[0064] The physical and chemical indicators of the product are shown in Table 3.

[0065] Table 3, the quality indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com