Method for maintaining crown of kiln

A technology of dome and kiln, applied in the field of glass preparation, which can solve the problems of eroding electric fused bricks at the bottom of the pool, increasing fuel consumption, affecting product quality, etc., and achieves the effect of solving difficult sealing, high load softening temperature, and not easy to erode and peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

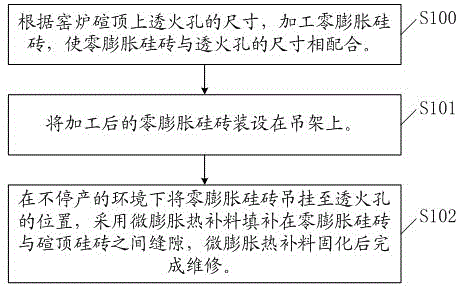

[0025] combine figure 1 , the present invention provides a kind of kiln crown maintenance method, comprises the following steps:

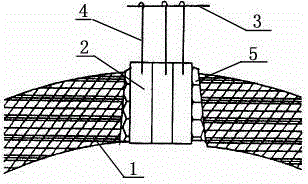

[0026] S100, according to the size of the fire hole on the roof of the kiln, process the zero-expansion silica brick, so that the zero-expansion silica brick matches the size of the fire hole.

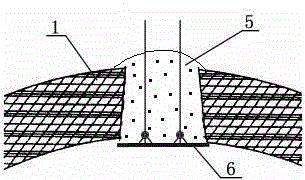

[0027] When the kiln roof is in a high temperature environment for a long time, there will be fire holes, which are potential safety hazards in production. In particular, the sizes and positions of the fire holes are different, and different maintenance methods need to be adopted for different sizes of fire holes. Under normal circumstances, the small-diameter fire hole only needs to be filled with micro-expansion heat filler, but if the hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com