High-stress-strain low-creepage high-thermal-shock-resistance refractory brick and manufacturing method thereof

A low-creep, refractory brick technology, applied in high thermal shock-resistant refractory bricks and its manufacture, low creep, high-load soft field, can solve the problems of poor creep, high frequency, poor seismic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

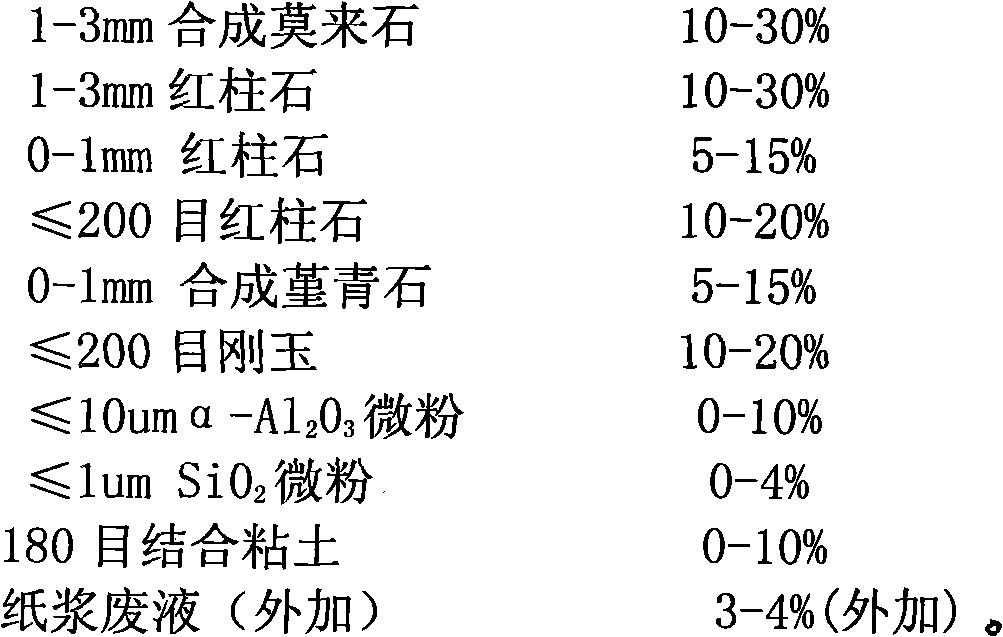

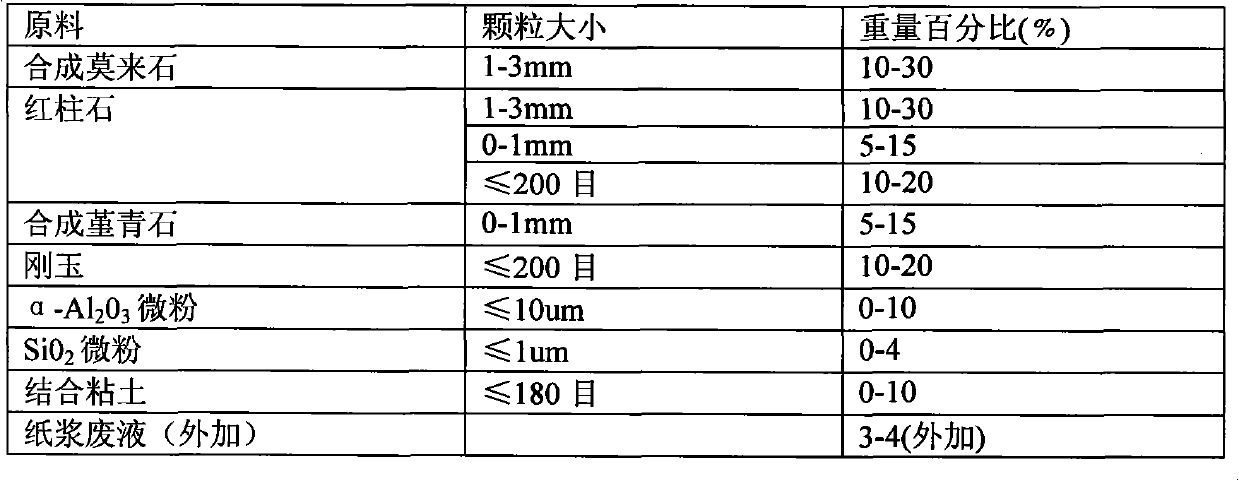

Method used

Image

Examples

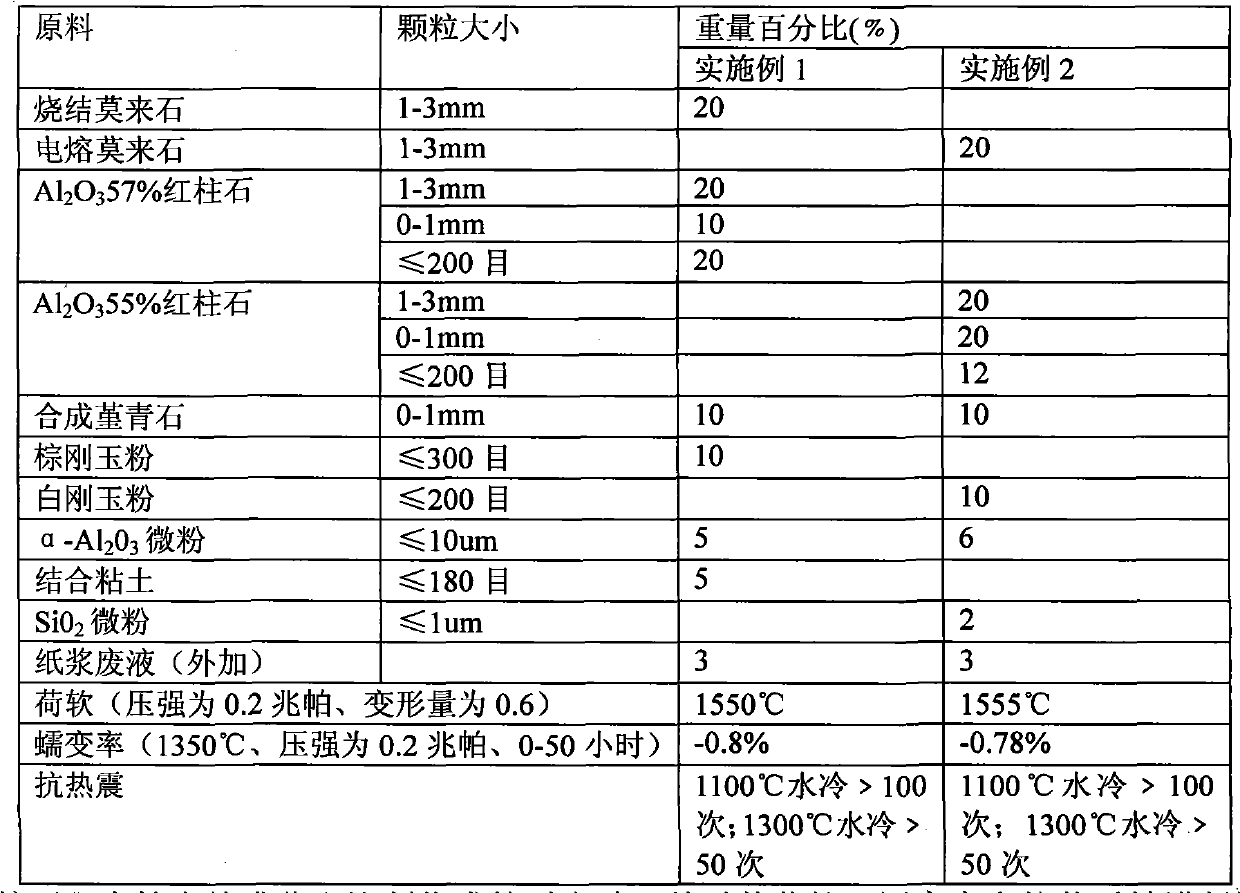

Embodiment 1

[0016] First, prepare the ingredients corresponding to Example 1 in Table 1 according to the listed weight percentages, put the ingredients into a wet mill and carry out wet milling, first thicken (1-3mm), medium (<1mm) particles, and then Add pulp waste liquid to make the pulp completely wet the particles, then add fine powder (≤180 mesh), knead evenly and then grind. Then put it in a friction brick press and press it into shape, and then put the formed green body into a drying kiln car, and push it into a tunnel dryer for drying. The dried body is loaded on the kiln car according to the kiln installation diagram, and pushed into the tunnel type firing kiln for firing. The maximum firing temperature is 1370°C-1400°C. The load softness, creep rate and thermal shock resistance of the refractory bricks were measured, and the test results are listed in Table 1.

Embodiment 2

[0018] Repeat the method of Example 1 according to the content of each component specified in Example 2 in Table 1, and test its softness under load, creep rate and thermal shock resistance.

[0019] Table 1

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com