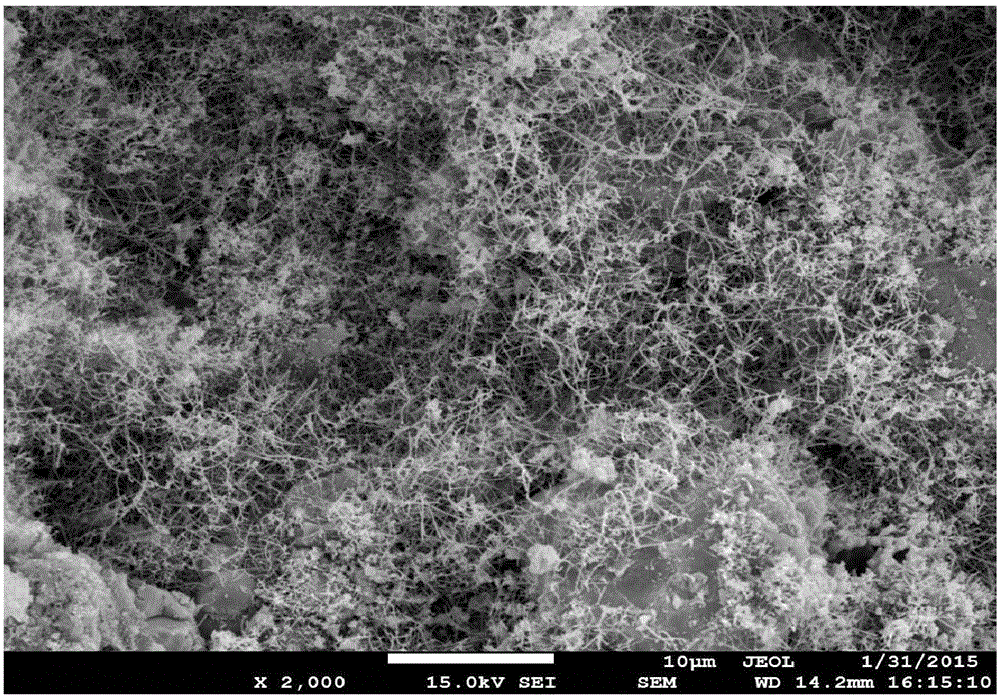

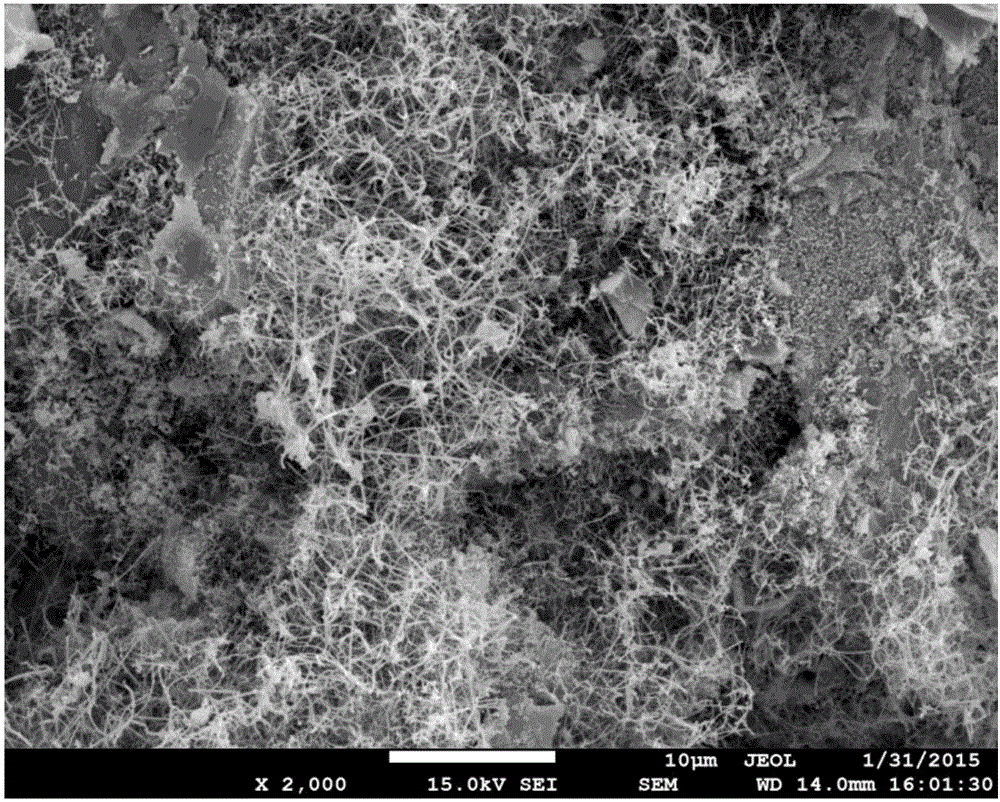

Silicon carbide whisker in-situ composite corundum high-temperature ceramic material and preparation method thereof

A silicon carbide whisker and in-situ composite technology, applied in the field of high-temperature ceramic materials, can solve the problems of small length and diameter of silicon carbide whiskers, high raw material cost, unfavorable sintering densification, etc., and achieve high strength at room temperature and high temperature, and softening under load The effect of high temperature and good volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

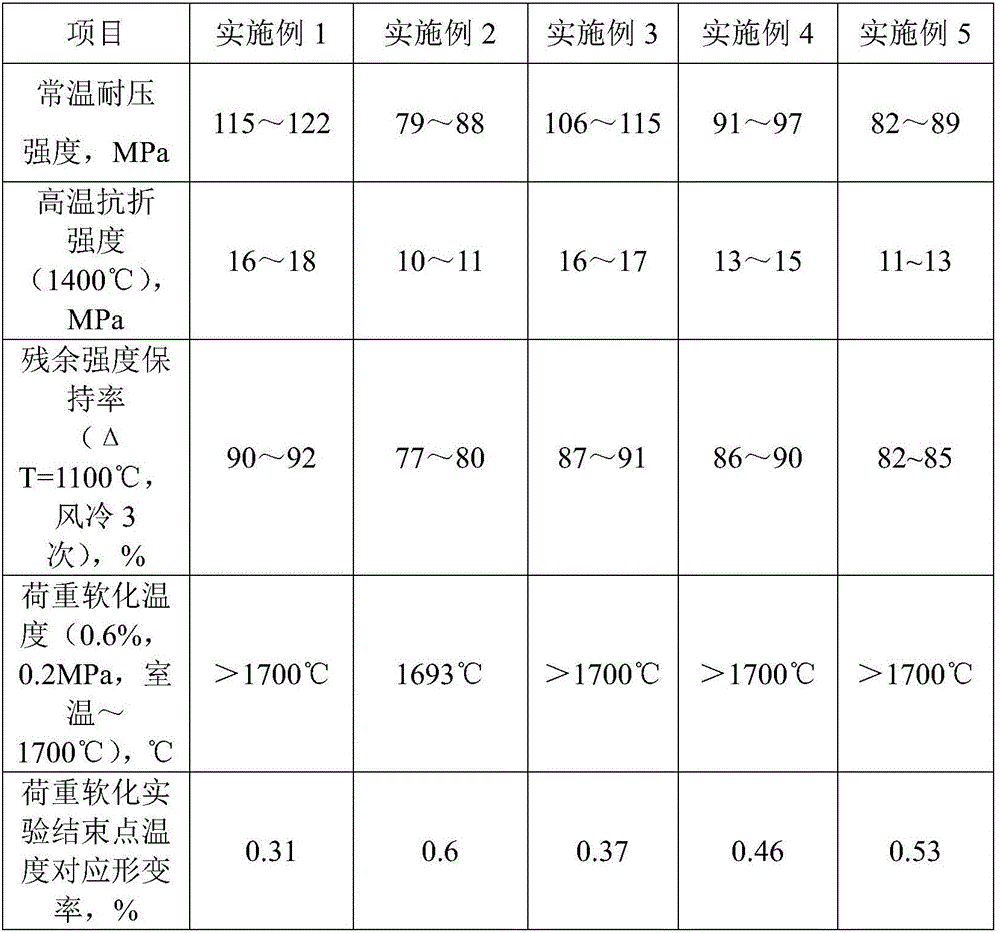

Examples

Embodiment 1

[0037] The silicon carbide whisker in-situ composite corundum high-temperature ceramic material of this embodiment is made of composite raw materials and a binder, and the composite raw materials are composed of the following raw materials in weight percentages: corundum powder 82%, carbonized rice husk powder 15%, carbon dioxide Silicon micropowder 1%, iron powder 1.5%, boric acid 0.5%, corundum powder particle size 45μm, carbonized rice husk powder chemical composition of C and SiO 2 The mass ratio of the compound is 0.67, the binding agent is a dextrin solution with a concentration of 35%, and the weight of the dextrin solution is 5% of the total weight of the composite raw material.

[0038] The carbonized rice husk powder of the present embodiment is obtained by the following method:

[0039] Dry the screened and cleaned rice husks, put them in a sagger and carbonize them in a vacuum furnace at 550°C for 1.5 hours, take them out after cooling, wet mill them with water for...

Embodiment 2

[0046] The silicon carbide whisker in-situ composite corundum high-temperature ceramic material in this embodiment is made of composite raw materials and binders, and the composite raw materials are composed of the following raw materials in weight percentage: corundum powder 91%, carbonized rice husk powder 7%, carbon dioxide Silica powder 0.5%, ferrous sulfate 1%, sodium chloride 0.5%, corundum powder particle size 88μm, carbonized rice husk powder chemical composition of C and SiO 2 The mass ratio is 0.63, the binder is 40% sulfurous acid pulp waste liquid, and the weight of the sulfurous acid pulp waste liquid is 4% of the total weight of the composite raw material.

[0047] The carbonized rice husk powder of the present embodiment is obtained by the following method:

[0048] Dry the screened and cleaned rice husks, place them in a sagger and carbonize them in a vacuum furnace at 700°C for 0.5h, take them out after cooling, wet mill them with water for 12h, and sieve them...

Embodiment 3

[0055] The silicon carbide whisker in-situ composite corundum high-temperature ceramic material in this embodiment is made of composite raw materials and binders, and the composite raw materials are composed of the following raw materials in weight percentages: corundum powder 82.5%, carbonized rice husk powder 15%, silicon powder 0.5%, boric acid 1.5%, sodium chloride 0.5%, corundum powder particle size is 45μm, carbonized rice husk powder chemical composition of C and SiO 2 The mass ratio is 0.72, the binder is 50% sulfurous acid pulp waste liquid, and the weight of the sulfurous acid pulp waste liquid is 5% of the total weight of the composite raw material.

[0056] The carbonized rice husk powder of the present embodiment is obtained by the following method:

[0057] Dry the screened and cleaned rice husks, place them in a sagger and carbonize them in a vacuum furnace at 500°C for 2 hours, take them out after cooling, wet mill them with water for 12 hours, dry them and sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com