Special castable for kiln mouth

A castable and kiln mouth technology, applied in the field of refractory materials, can solve the problems of poor thermal shock resistance, increased material cost, unguaranteed service life, etc., to achieve strong wear resistance and thermal shock resistance stability, alkaline gas The effect of strong erosion ability and meeting the requirements of use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

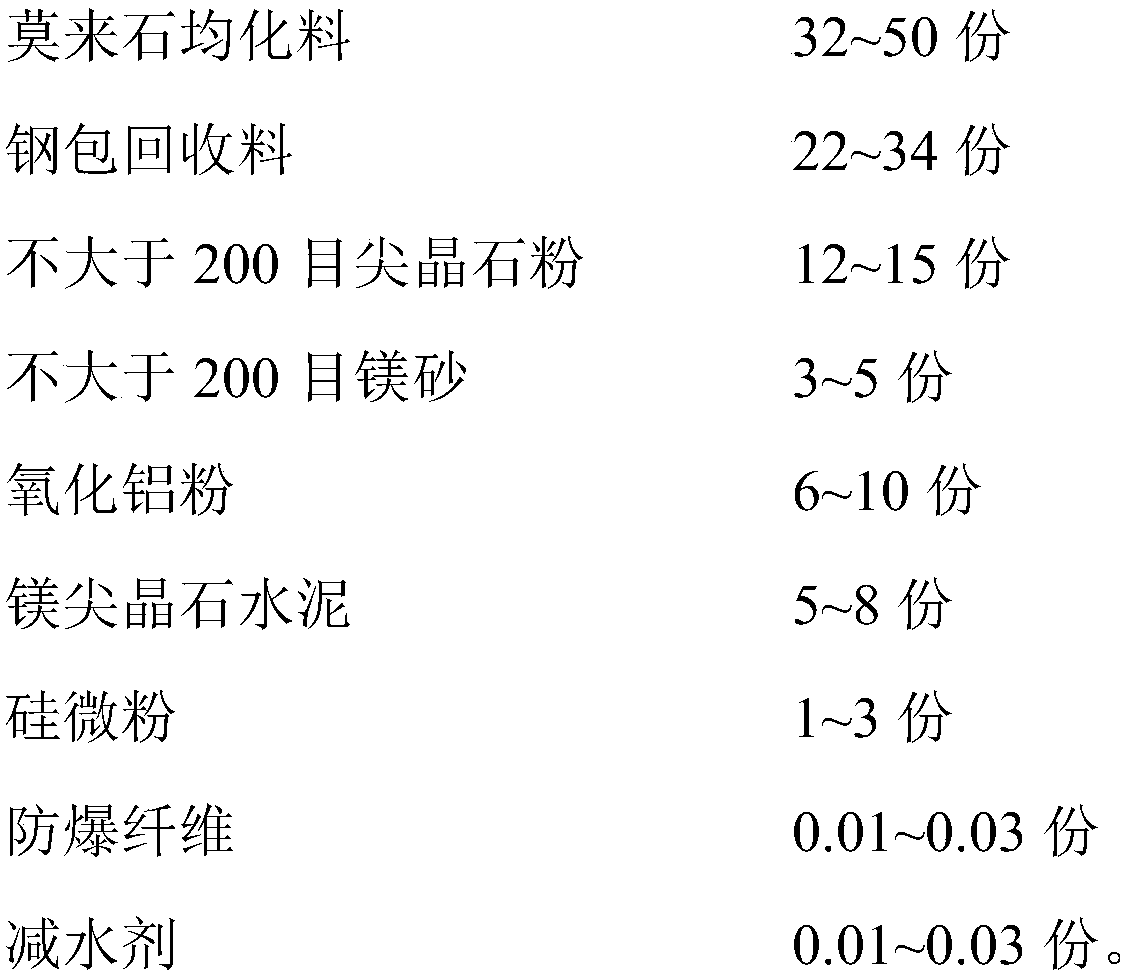

[0020] A special castable for kiln mouth, comprising the following components and parts by weight:

[0021]

[0022]

[0023] Firstly, the ladle recycled materials are processed into 5-3mm, 3-1mm, and 1-0mm specifications after crushing, screening, and iron removal, and then the above-mentioned various raw materials are weighed in proportion and mixed evenly in a mixer to obtain a A special castable for the kiln mouth. Wherein, the Al in the ladle reclaimed material 2 o 3 The mass percentage content of MgO is not less than 70%, and the mass percentage content of MgO is not less than 10%; the Al in the spinel 2 o 3 The mass percentage content is not less than 72%; Al in the magnesium spinel cement 2 o 3 The mass percentage of MgO is not less than 68%, the mass percentage of MgO is not less than 18%, and the mass percentage of CaO is not more than 12%.

Embodiment 2

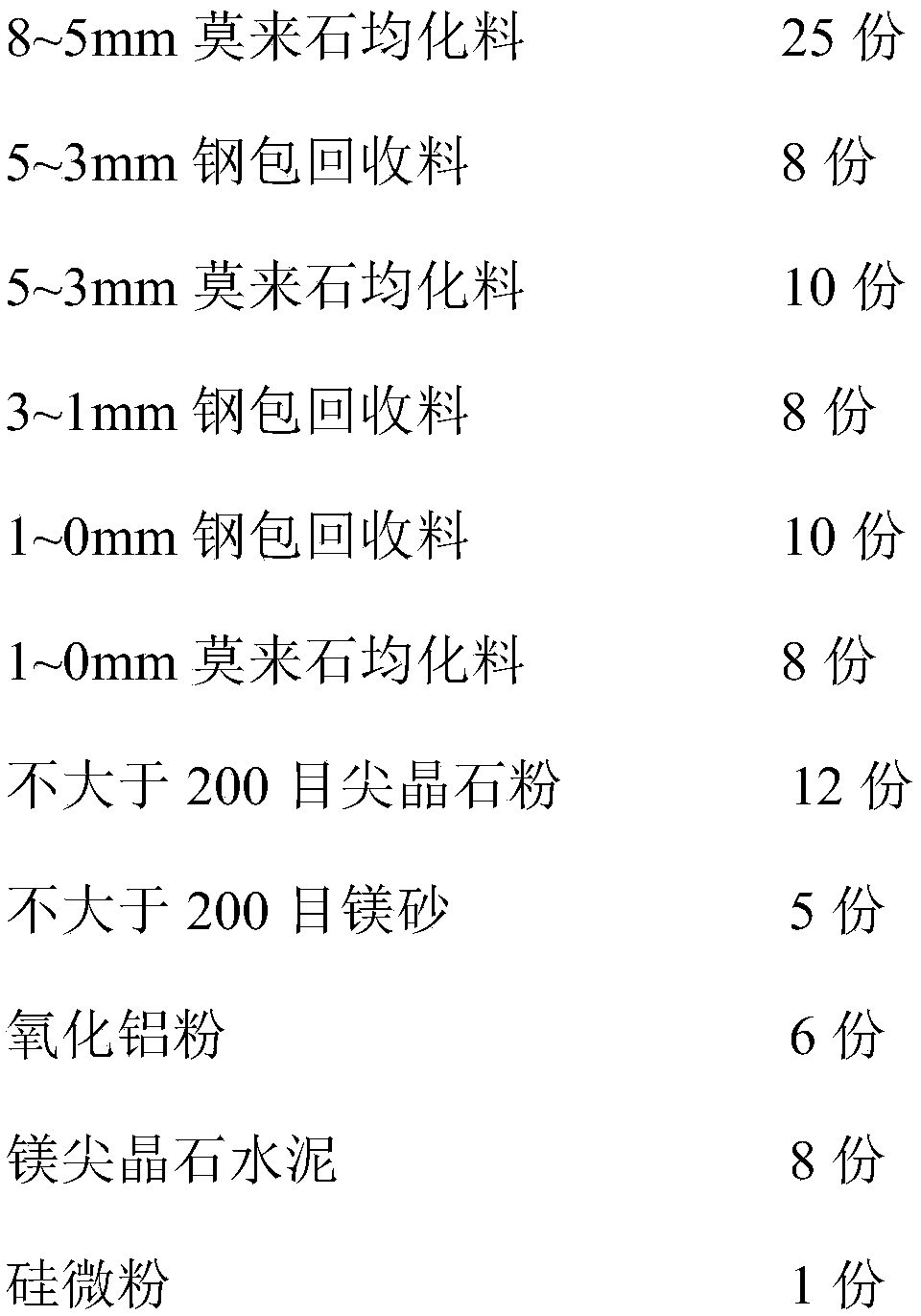

[0025] A special castable for kiln mouth, comprising the following components and parts by weight:

[0026]

[0027] Firstly, the ladle recycled materials are processed into 5-3mm, 3-1mm, and 1-0mm specifications after crushing, screening, and iron removal, and then the above-mentioned various raw materials are weighed in proportion and mixed evenly in a mixer to obtain a A special castable for the kiln mouth. Wherein, the Al in the ladle reclaimed material 2 o 3 The mass percentage content of MgO is not less than 70%, and the mass percentage content of MgO is not less than 10%; the Al in the spinel 2 o 3 The mass percentage content is not less than 72%; Al in the magnesium spinel cement 2 o 3 The mass percentage of MgO is not less than 68%, the mass percentage of MgO is not less than 18%, and the mass percentage of CaO is not more than 12%.

Embodiment 3

[0029] A special castable for kiln mouth, comprising the following components and parts by weight:

[0030]

[0031] Firstly, the ladle recycled materials are processed into 5-3mm, 3-1mm, and 1-0mm specifications after crushing, screening, and iron removal, and then the above-mentioned various raw materials are weighed in proportion and mixed evenly in a mixer to obtain a A special castable for the kiln mouth. Wherein, the Al in the ladle reclaimed material 2 o 3 The mass percentage content of MgO is not less than 70%, and the mass percentage content of MgO is not less than 10%; the Al in the spinel 2 o 3 The mass percentage content is not less than 72%; Al in the magnesium spinel cement 2 o 3 The mass percentage of MgO is not less than 68%, the mass percentage of MgO is not less than 18%, and the mass percentage of CaO is not more than 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com