Method for producing cold rolling domestic appliance plate using cover type oven

A bell-type furnace and home appliance technology, which is applied in the field of annealing process of cold-rolled plate bell-type furnaces, can solve problems that have not yet been seen, and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The mass percentage of chemical composition of cold-rolled coil is: C 0.08, Si 0.024, Mn 0.50, P 0.017, S 0.005, Als 0.05, N 0.004, Nb 0.03, and the rest is Fe and trace impurities.

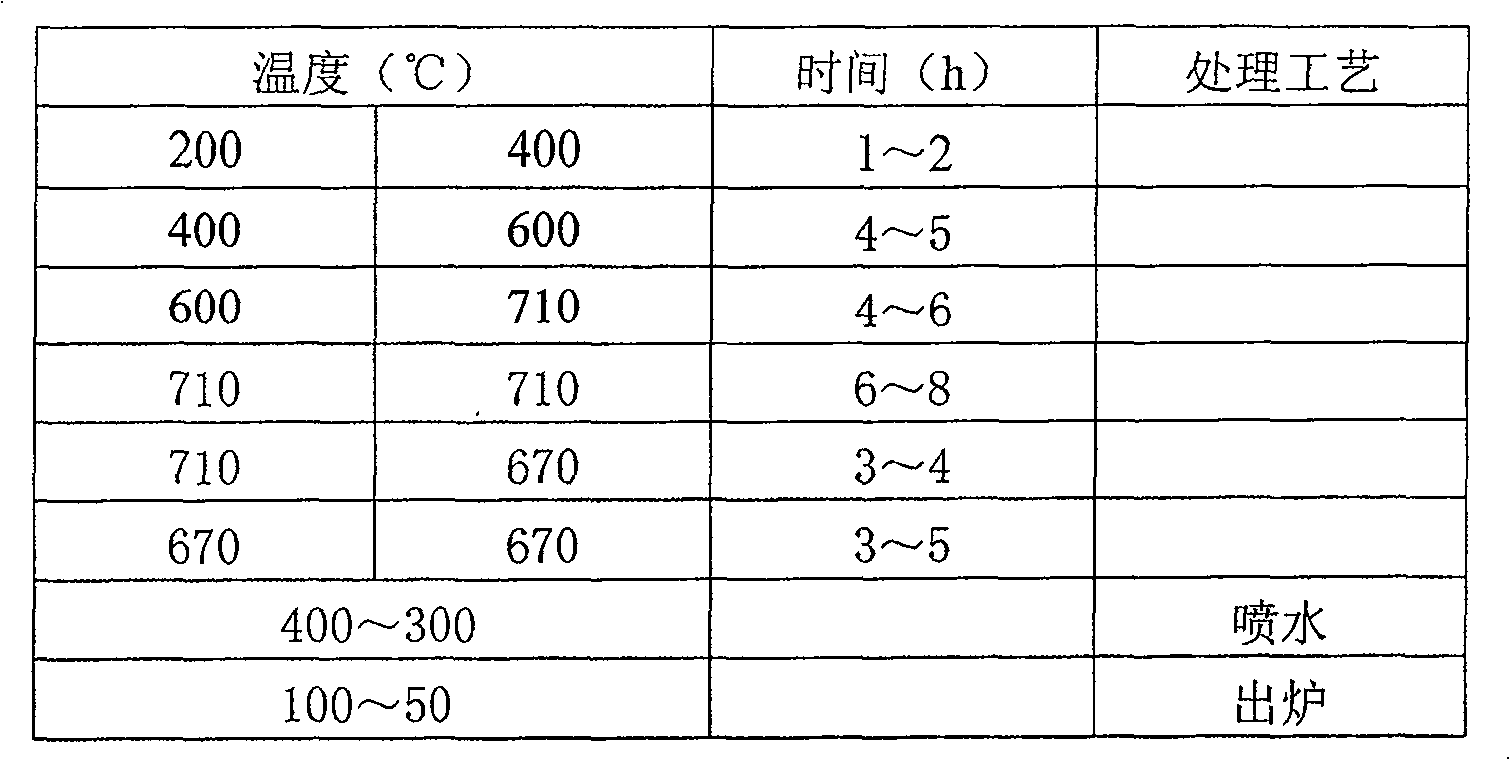

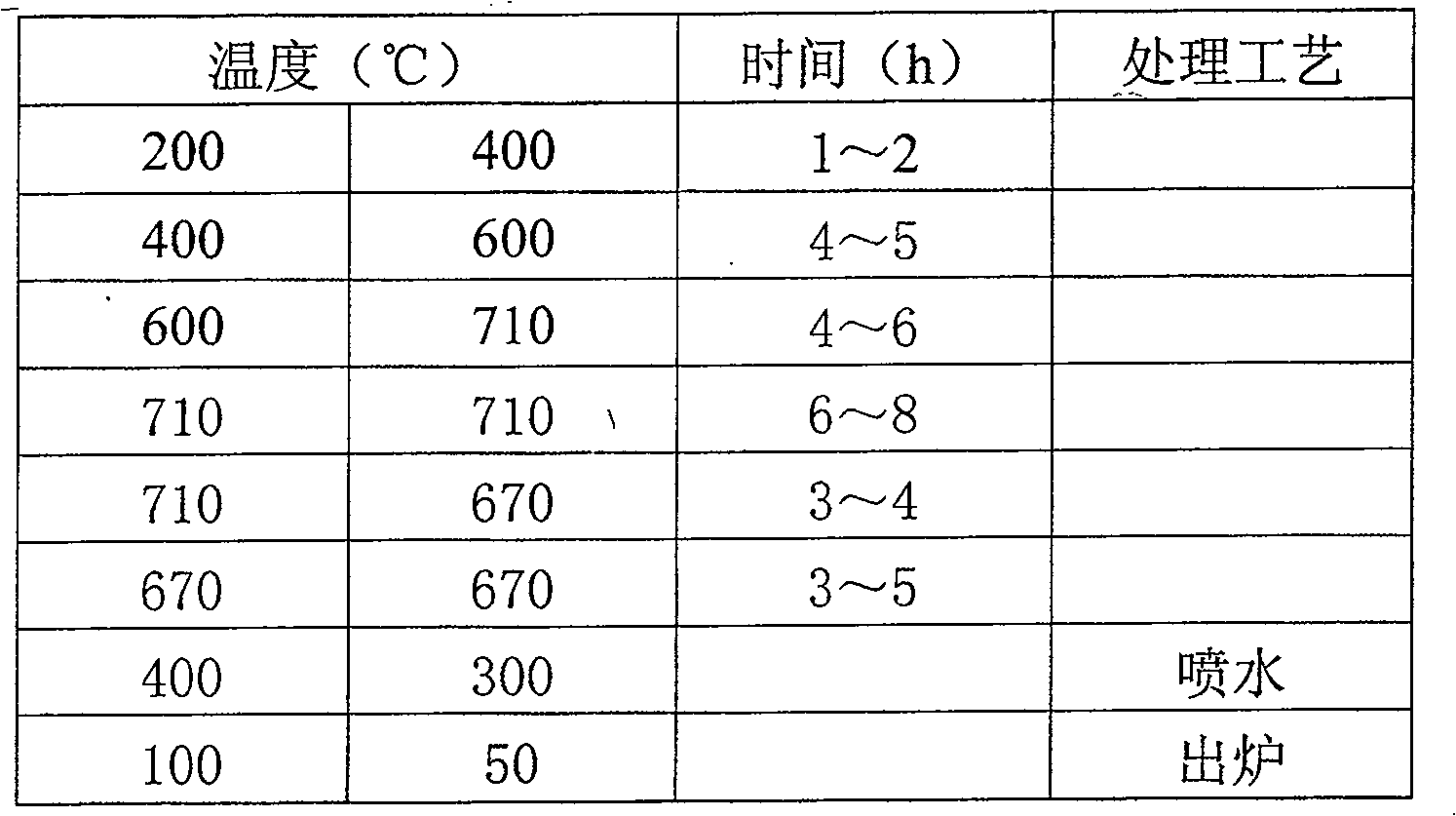

[0020] The bell furnace annealing process system adopted is:

[0021] Install the furnace according to the conventional method of bell-type furnace, and gradually raise the temperature to 200°C after installation

[0022] It takes 1.5 hours to raise the temperature from 200°C to 400°C; then use 5 hours to raise the temperature to 600°C at a constant speed; after 5 hours, the temperature slowly rises to 710°C; then keep the temperature at 710°C for 6 hours; 670°C; keep warm for 4 hours and then cool down; when the temperature drops to 400°C, spray water on the annealed coil; finally, when the temperature drops to 50°C, it is out of the furnace.

Embodiment 2

[0024] The mass percentage content of the chemical composition of the coil is: C0.10, Si0.03, Mn0.26, P0.02, S0.010, Als0.036, N0.0018, Nb0.016, and the rest is Fe and trace impurities.

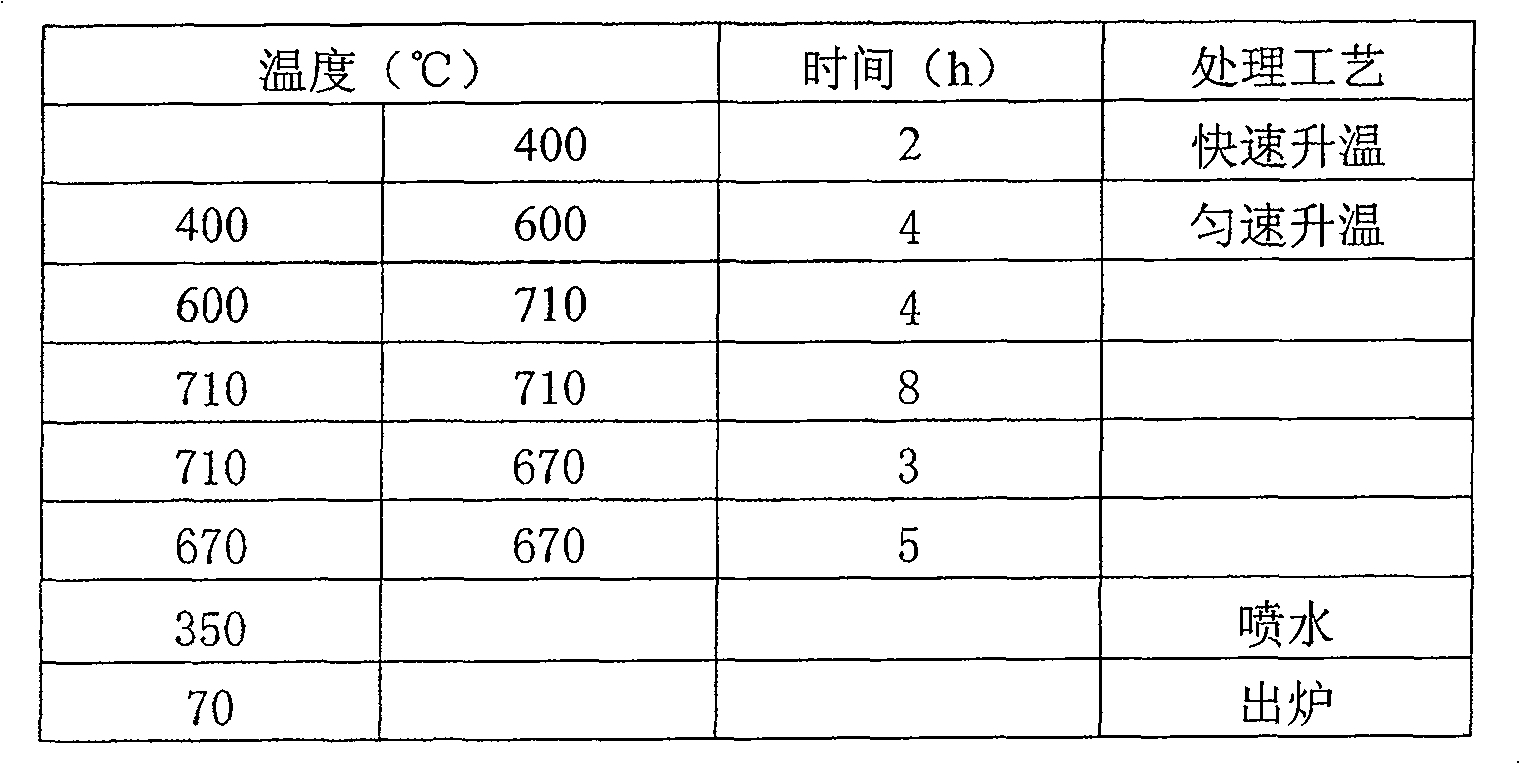

[0025] The selected annealing process system is:

[0026] Rapidly raise the temperature to 400°C in 2 hours; raise the temperature to 600°C at a uniform speed for 4 hours; slowly raise the temperature to 710°C after 4 hours; keep at 710°C for 8 hours; then slowly cool down to 670°C for 5 hours; then cool down to 350°C When the temperature drops to 70°C, the annealed sheet will be rolled out of the furnace.

[0027] By implementing the above composition and annealing system, a cold-rolled home appliance panel with a yield ratio of 0.80 and an elongation rate of 30% can be obtained, which can fully meet the requirements of users for high yield ratio and higher elongation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com