HDPE winding structure wall B type pipe with lining as fireproof layer and manufacturing process thereof

A technology of fireproof layer and structural wall, applied in the direction of pipes, rigid pipes, pipeline protection, etc., to achieve the effect of simple construction, expansion of use scope, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

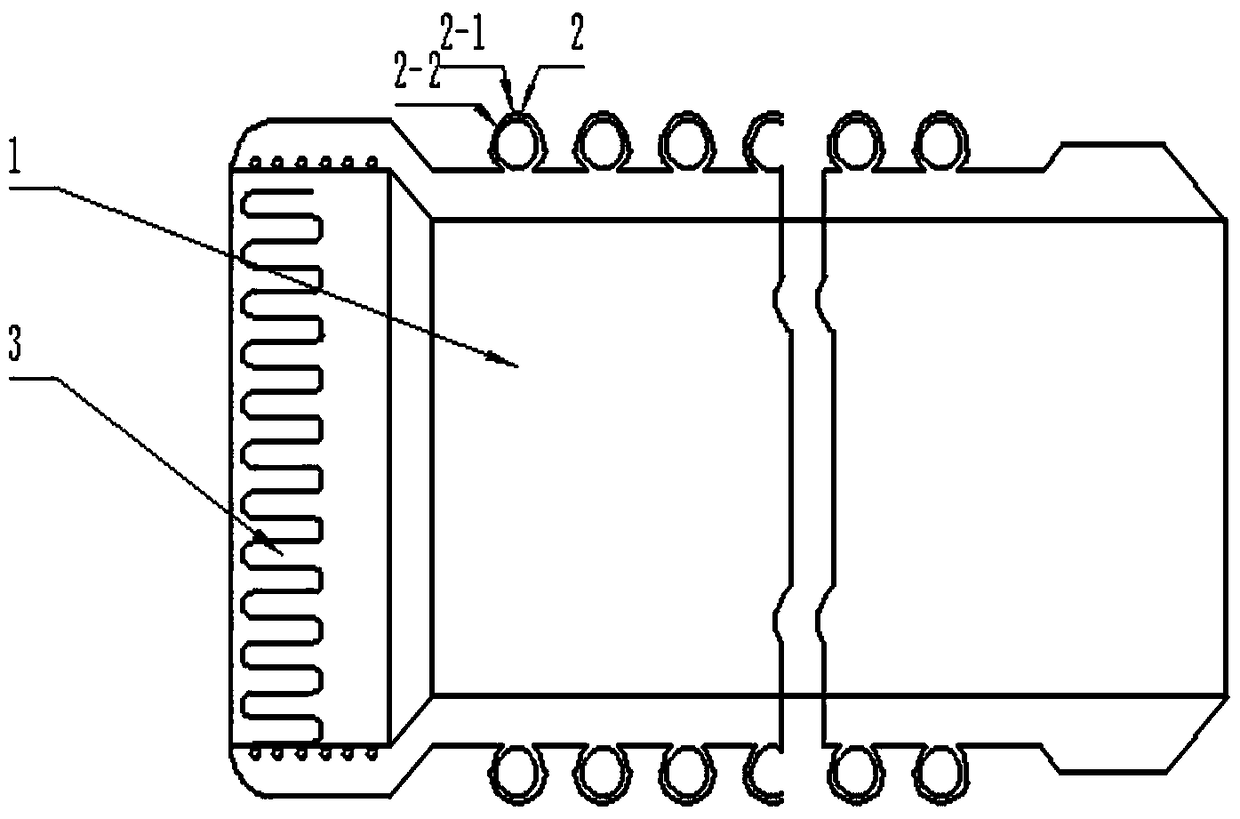

[0023] Such as figure 1 As shown, the present invention is designed as an embodiment of a fireproof HDPE winding structure wall B-type pipe, which includes a main pipe 1 made of ordinary polyethylene raw materials, and a PP ribbed pipe 2 arranged outside the main pipe 1. The inner wall of the main pipe 1 is compounded with an inner lining layer made of flame-retardant and fire-resistant materials, and an electric fuse 3 is embedded in the nozzle of the main pipe.

[0024] The inner lining layer composed of flame-retardant and fire-resistant materials is made of compound flame-retardant materials composed of high-density polyethylene raw materials and flame-retardant masterbatches accounting for 5-30% of the total weight.

[0025] The flame retardant masterbatch used is bromine antimony flame retardant masterbatch or phosphorus flame retardant masterbat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com