Local anodic oxidation method for surface of workpiece

A local anodizing and workpiece surface technology, applied in the field of electrochemical treatment, can solve problems affecting product appearance and performance, product scrapping, repeated positioning errors, etc., to avoid poor repeating positioning accuracy, reduce processing costs, and increase adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is to illustrate the application when the surface of the workpiece to be anodized that does not need to be oxidized is a plane.

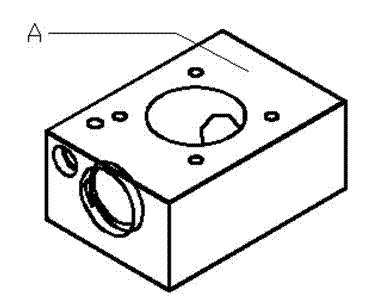

[0028] ① Preparation of samples: figure 1 It is a hydraulic valve body used in the brake system of new energy vehicles. Due to some functional requirements of the valve body, the A side does not need anodizing;

[0029] ② Put the sample into the surface treatment solution (chromic acid: 20-30g / l, phosphoric acid: 20-25%, and the rest is water) for treatment at a temperature of 50-60°C and a treatment time of 20-30 seconds;

[0030] ③ Wash the surface treatment solution with water, and dry the surface of the sample;

[0031] ④ Adhesive tape: Paste the surface A of the sample treated in step ③ with polyimide tape. Use a hard rubber plate to squeeze and slide on the surface of the tape in one direction, stick the surface of the workpiece to the tape and drive away the air bubbles on the surface of the tape and the workpiece;

...

Embodiment 2

[0036] This embodiment is intended to illustrate the application when the surface of the workpiece to be anodized that does not need to be oxidized is a cylindrical surface.

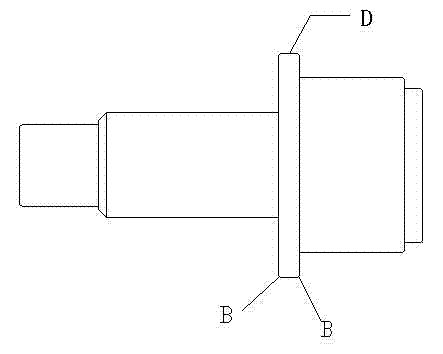

[0037] ① Preparation of samples: figure 2 It is a battery piston used in the braking system of new energy vehicles. Due to the requirements of the piston for electrical conductivity, the D surface of the cylinder does not need anodic oxidation;

[0038] ② Put the sample into the surface treatment solution (chromic acid: 20-30g / l, phosphoric acid: 20-25%, and the rest is water) for treatment at a temperature of 50-60°C and a treatment time of 20-30 seconds;

[0039] ③ Wash the surface treatment solution with water, and dry the surface of the sample;

[0040] ④ Adhesive tape: Paste the surface D of the sample treated in step ③ with polyimide tape. Use a hard rubber plate to squeeze and slide on the surface of the tape in one direction, stick the surface of the workpiece to the tape and drive away the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com