Pellet binder and adding device and adding method thereof

A binder and pellet technology, which is applied in chemical instruments and methods, dissolution, mixers, etc., can solve the problems of pellet grade reduction and achieve the effects of simple preparation method, reduced dosage, and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 600 kg of chrysanthemum root powder, 300 kg of sodium carboxymethyl cellulose powder, and 100 kg of montmorillonite, and dry mix them uniformly to make the pellet binder of the present invention.

[0022] The addition method of pellet binder is:

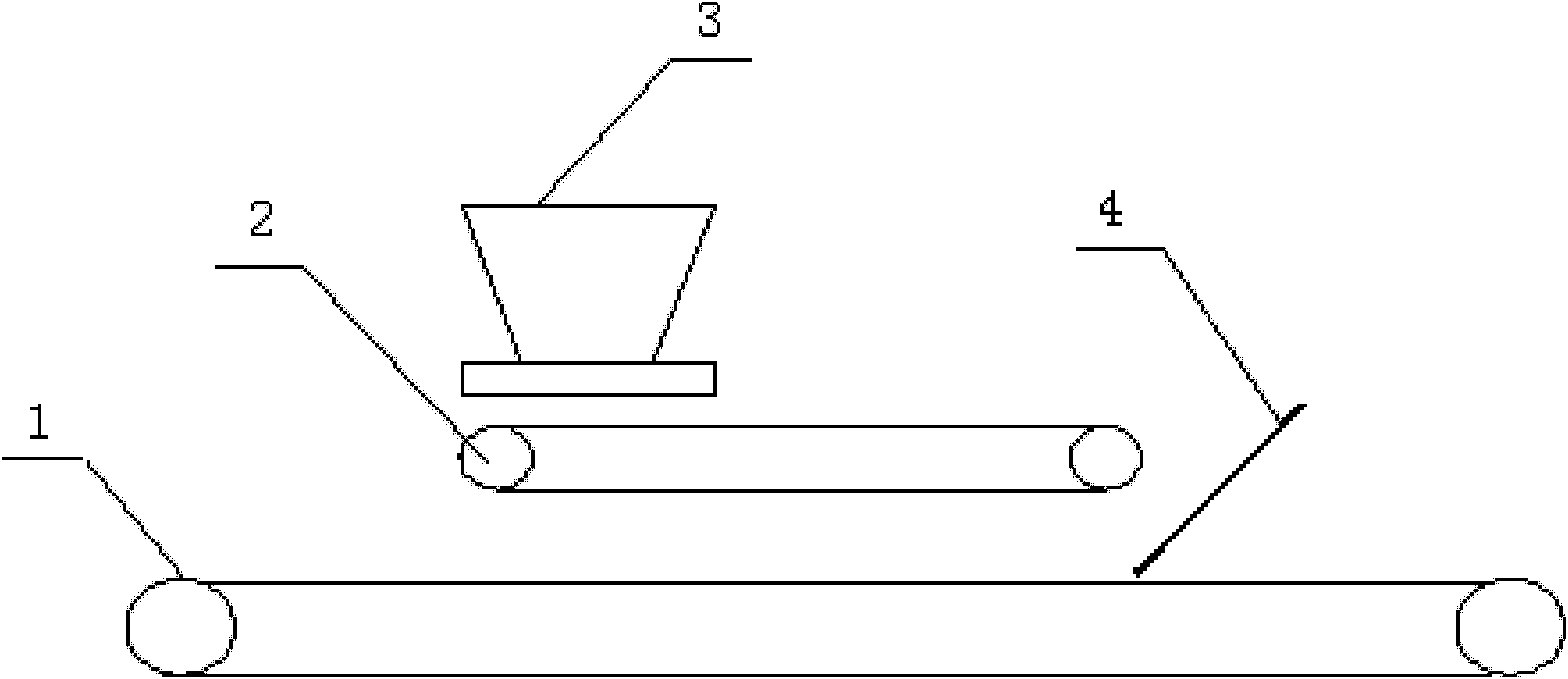

[0023] First of all, according to the weight of the pellet mixture transported by the material belt 1 per unit time and unit length, the weight of the binder to be added and the distribution of the binder on the electronic belt scale 2 are calculated correspondingly, as the electronic belt scale 2 According to the matching and adding basis, and set the amount of material spread per unit time and unit length of the adhesive powder point on the electronic belt scale 2.

[0024] Then, the prepared binder powder is loaded into the binder tank 3 in batches. Open the binder tank 3, and the electronic belt scale 2 adds binder to the pellet mixture according to the weight of the binder to be transported per unit time and unit l...

Embodiment 2

[0026] Weigh 630 kg of chrysanthemum root powder, 290 kg of sodium carboxymethyl cellulose powder, and 80 kg of montmorillonite, and dry mix them uniformly to make the pellet binder of the present invention.

[0027] The addition method of pellet binder is:

[0028] First of all, according to the weight of the pellet mixture transported by the material belt 1 per unit time and unit length, the weight of the binder to be added and the distribution of the binder on the electronic belt scale 2 are calculated correspondingly, as the electronic belt scale 2 According to the matching and adding basis, and set the amount of material spread per unit time and unit length of the adhesive powder point on the electronic belt scale 2.

[0029] Then, the prepared binder powder is loaded into the binder tank 3 in batches. Open the binder tank 3, and the electronic belt scale 2 adds binder to the pellet mixture according to the weight of the binder to be transported per unit time and unit le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com