Coke-oven heating system with variable heating height for gas-rich heating and adjustment method thereof

A gas-rich, highly advanced technology, applied in combustible gas heating coke ovens, coke ovens, coke oven heating, etc., can solve problems such as increased construction costs and production costs, increased difficulty in making bricks, and increased heat consumption in coking to achieve savings Construction costs and production costs, reduction of coke oven nitrogen oxide emissions, and the effect of reducing the generation of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

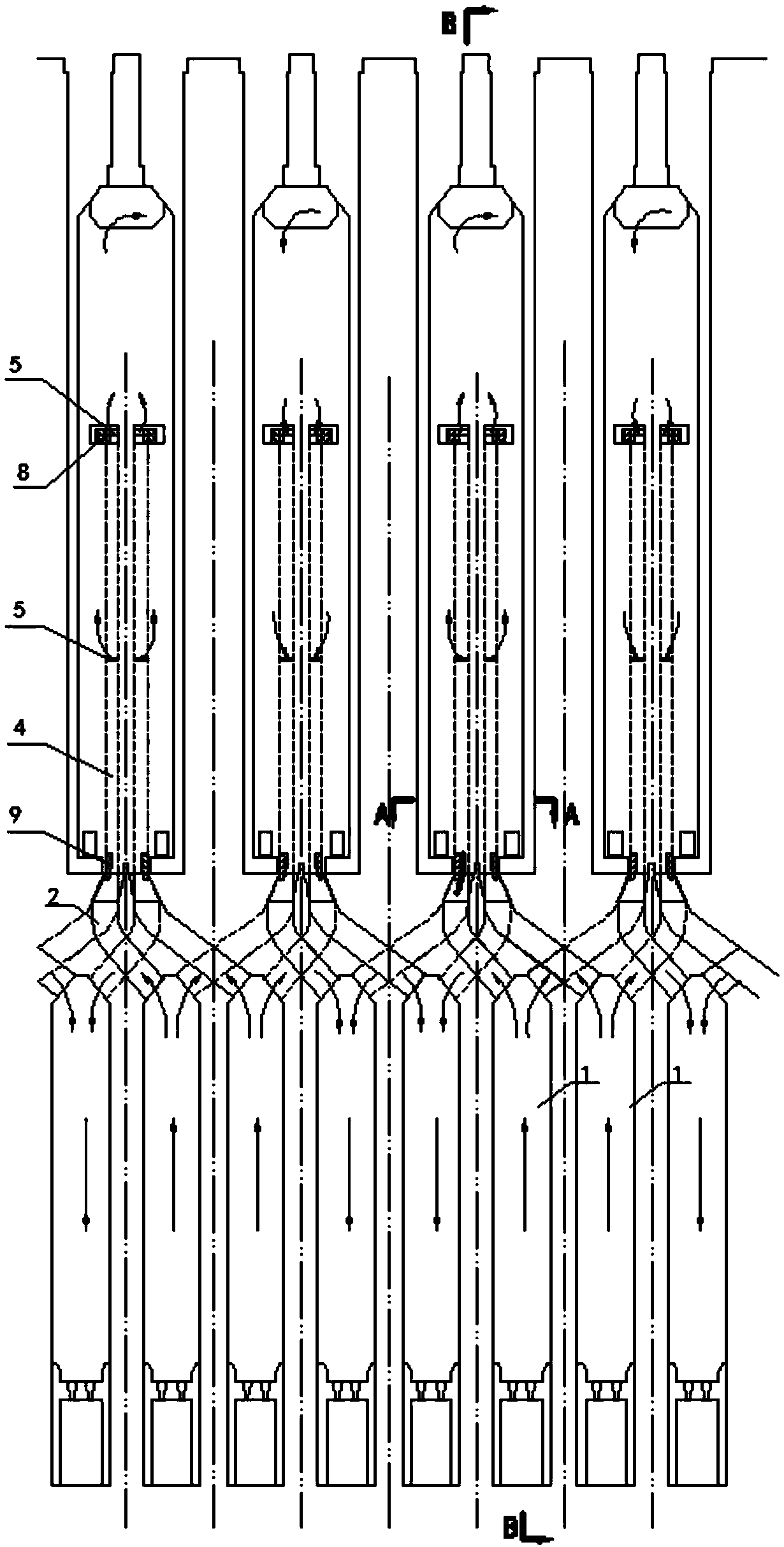

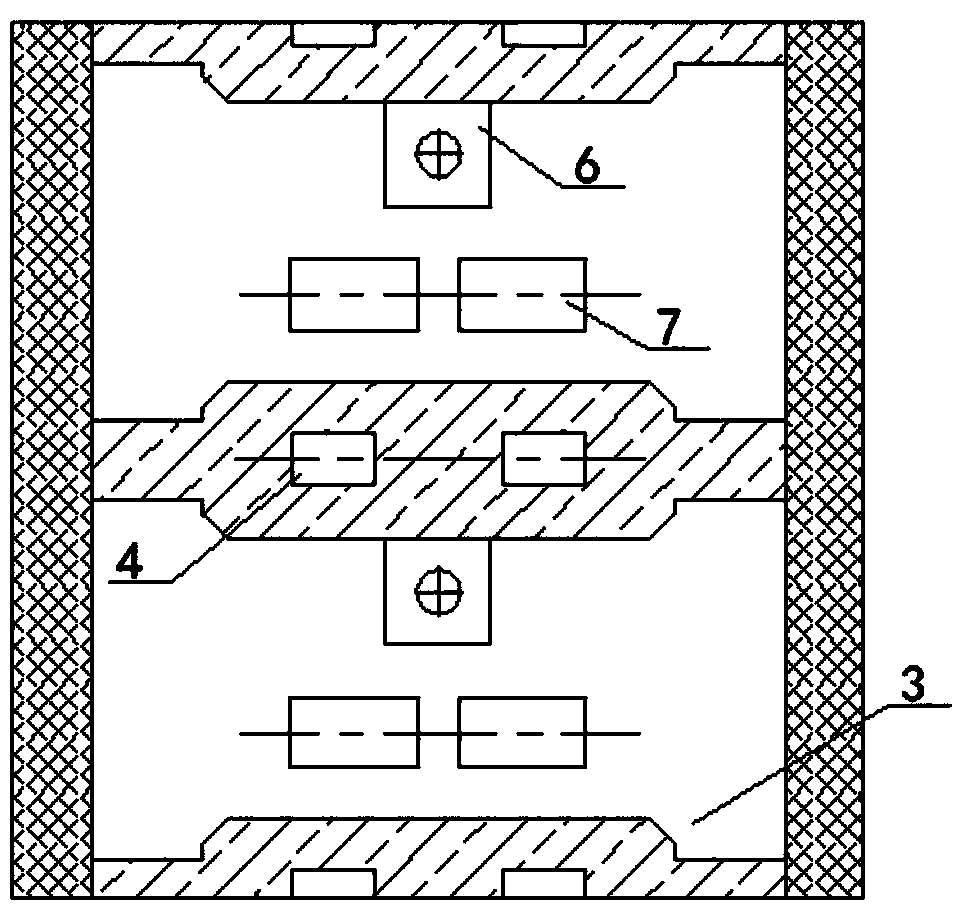

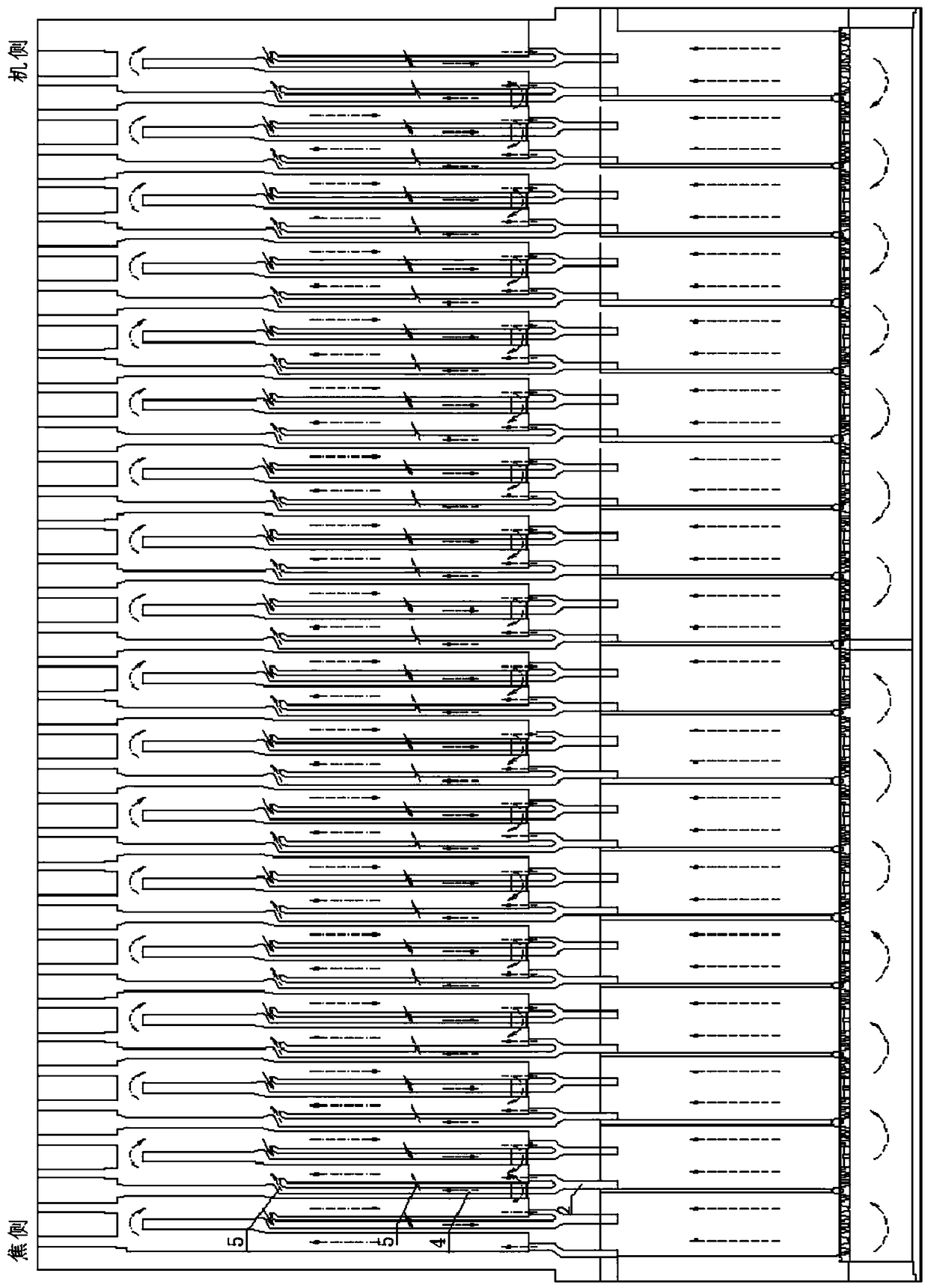

[0031] Such as Figure 4-Figure 10 As shown, the coke oven heating system with variable heating height of the rich gas heating in the present invention includes a small flue 11, a controllable heat exchange channel 10, a combustion-supporting gas channel 15 and a combustion chamber connected sequentially from bottom to top; The number of controllable heat exchange channels 10 corresponding to the chamber is at least 2, and each controllable heat exchange channel 10 communicates with the combustion chamber through a corresponding combustion-supporting gas channel 15; The upper straight section is formed, and the straight section extends upwards into the fire passage 3, and each combustion-supporting gas passage 15 communicates with the fire passage 3 through at least one airflow outlet 16, and the airflow outlet 16 on each combustion-supporting gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com