Peanut picker

A technology of peanut fruit picking machine and fruit picking roller, which is applied in the direction of agricultural machinery and equipment, threshing equipment, application, etc., and can solve the problems of unclean picking of peanuts, low picking rate, and high crushing rate of peanuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

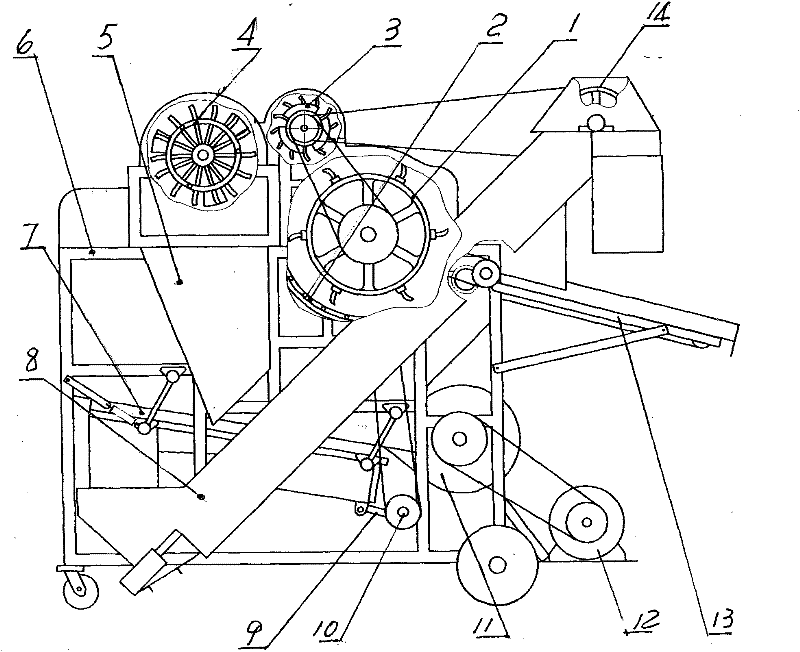

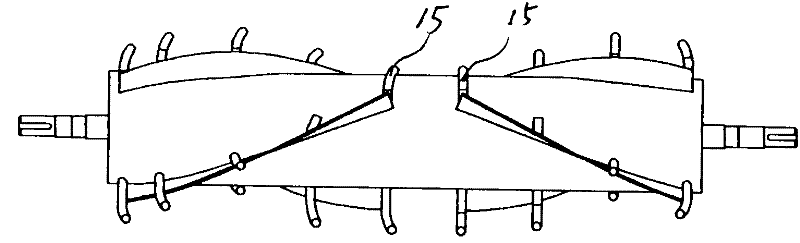

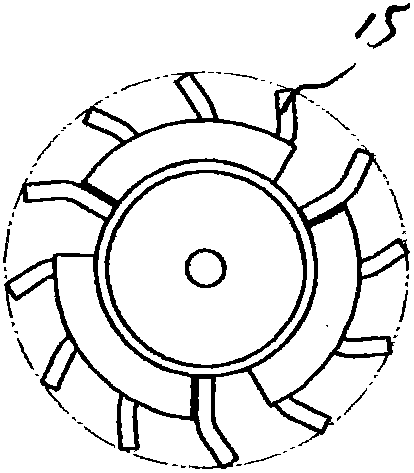

[0005] The present invention is described in detail in conjunction with the above accompanying drawings. In order to solve the problem that the dry fruit picker and the wet fruit picker cannot replace each other, the present invention adopts three fruit picking rollers, and the lower part of the first fruit picking roller 1 is provided with a cage grid 2 smaller than a semicircle. The structure of this first picking roller is identical with the picking roller of existing peanut picking machine. The second fruit picking roller 3 is arranged between the first fruit picking roller and the third fruit picking roller 4, and the bottom of the third fruit picking roller peripheral surface is provided with a cage grid less than a semicircle, and the second fruit picking roller is not provided with a cage grid. The upper part of the peripheral surface of the fruit picking roller is respectively provided with a shell to connect with the cage below it, wherein the adjacent joints of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com