Suspension ladder gravity flow impact foaming mine tailing recycling technology, and device thereof

A recycling and tailings technology, which is applied in flotation, solid separation, wet separation, etc., can solve the problems of high cost and complex zinc metal recovery process, and achieve low requirements for use conditions, good practical operation effect, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

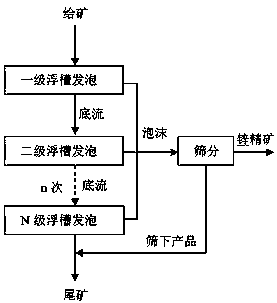

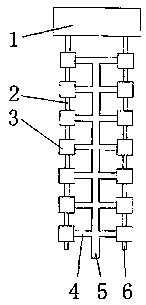

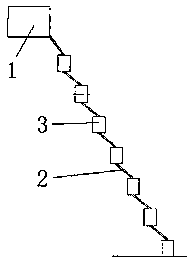

[0025] Such as Figure 1-6 As shown, a single floating tank test was carried out on zinc tailings in a dressing plant, and two sets of suspension ladder self-flow impact foaming tailings recovery devices were prepared. Each device included a tailings slurry pool 1 for containing zinc tailings slurry 8 , pulp pipeline 2, unpowered floating tank 3, foam tunnel 5, discharge pipe 6, the tailings pulp pool 1 is connected to the first pulp port 21 of the unpowered floating tank 3 through the pulp pipeline 2, and the unpowered floating tank 3 has a Block the zinc tailings slurry 8 to cause it to oscillate to form the baffle 31 of the foam 7, the foam outlet 4 of the floating tank for discharging the foam 7, the foam outlet 4 of the floating tank is connected with the foam corridor 5, and the first stage of the unpowered floating tank 3 The second pulp port 22 is connected to the first pulp port 21 of the second-stage non-powered floating tank 3 through the pulp pipeline 2 , and the s...

specific Embodiment 2

[0037] Such as Figure 1-5 As shown in , 7, the industrial test of floating tank-screening combined process was carried out on the zinc tailings of a certain dressing plant. According to the particle size of the zinc tailings, the zinc mineral distribution rate is basically above 0.15mm, and the zinc metal distribution rate of the zinc tailings is 68.66%. , due to the similar buoyancy of coarse-grained zinc minerals and fine-grained pyrite, the floating tank foam is used to enter the 0.22mm mesh vibrating fine screen, the product on the screen is low-grade zinc concentrate, and the product under the screen is combined with the tailings in the floating tank As floating zinc tailings.

[0038] Prepare 4 sets of suspension ladder self-flow impact foaming tailings recycling devices, a set of devices includes tailings slurry pool 1 for containing zinc tailings slurry 8, slurry pipeline 2, unpowered floating tank 3, foam tunnel 5, discharge Pipe 6, the tailings slurry pool 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com