Mechanical kneading method for clothes and kneading type washing machine

A mechanical and washing machine technology, applied in the field of mechanical rubbing and washing clothes and rubbing washing machines, can solve the problems of insufficient friction of clothes, high power and water consumption, and high detergent consumption, etc., and achieve easy implementation and low detergent consumption. Small amount, fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

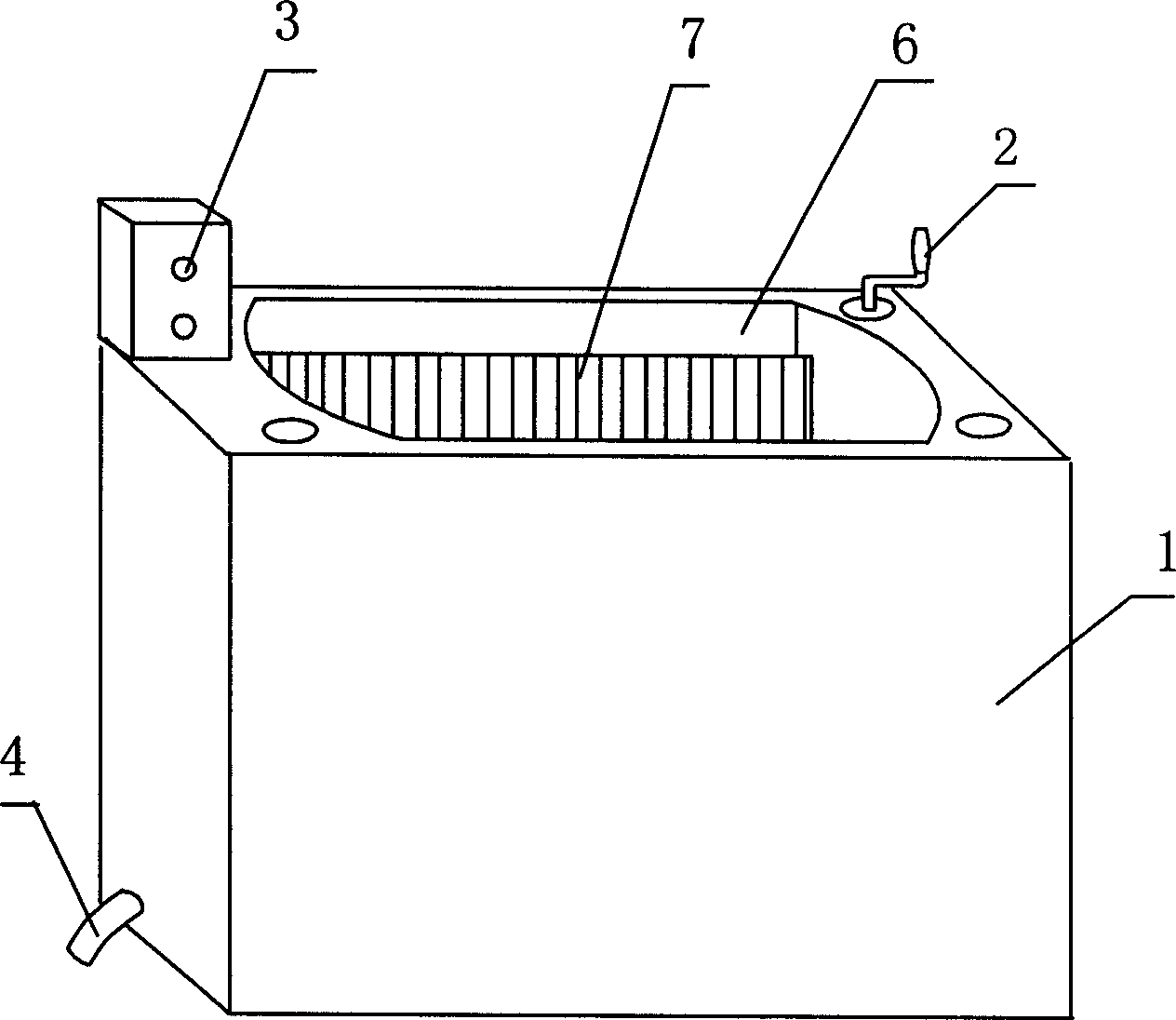

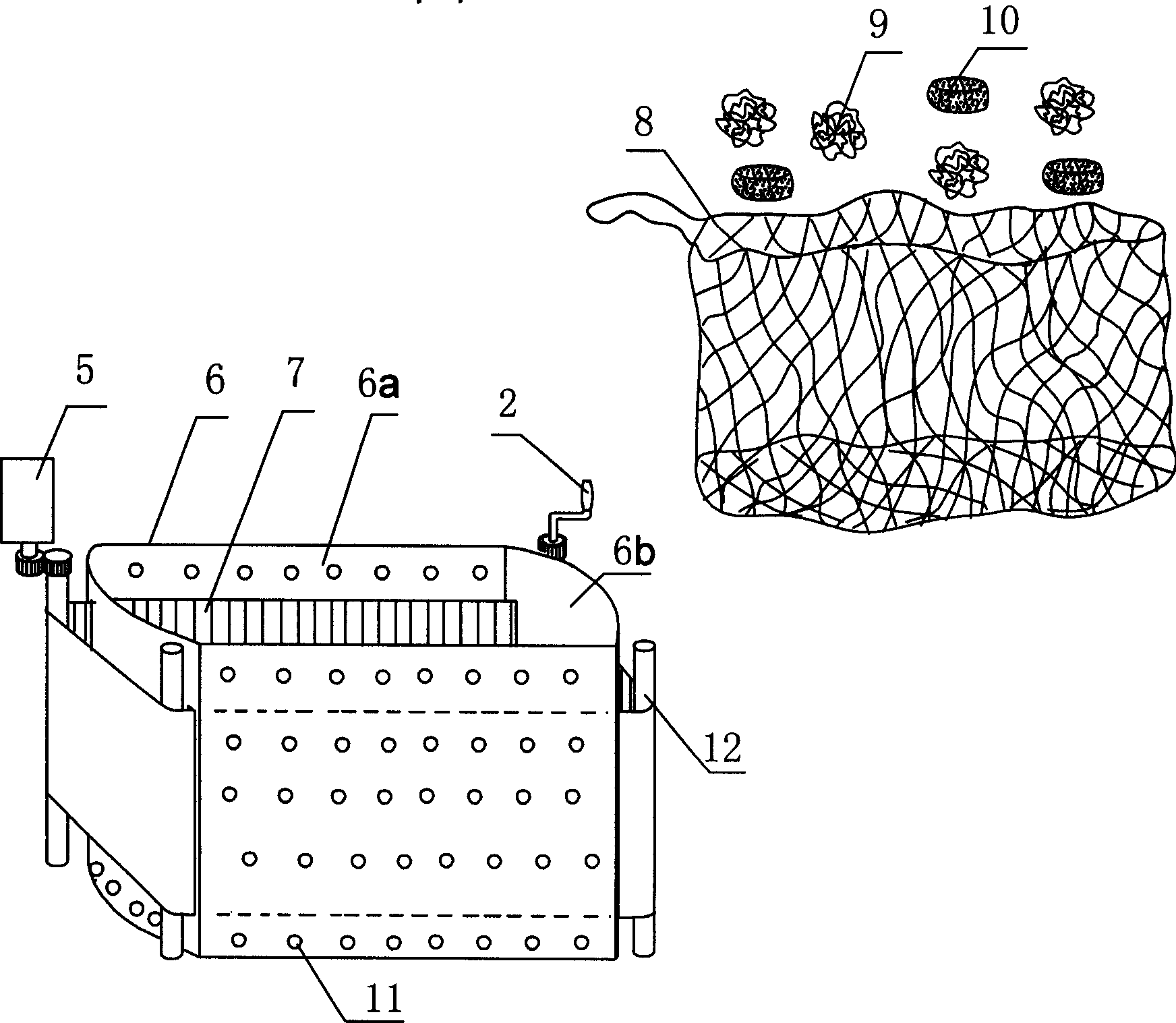

[0018] In this example, the lower part of the outer barrel 1 with the upper opening is provided with a water outlet 4, and the side wall and bottom surface of the inner barrel 6 are provided with a water hole 11 communicating with the inner cavity of the outer barrel, so that the water in the inner and outer barrel cavities can communicate more smoothly. , can also make the water in the inner bucket drain more smoothly.

[0019] The inner barrel 6 is in the shape of a flat column with a transverse diameter greater than the longitudinal diameter in cross section, and the longitudinal side walls 6b on both sides of the inner barrel are curved surfaces bulging outward. Twice of that, the longitudinal sidewalls 6b on both sides are curved surfaces bulging outwards, which will be more conducive to the rotation of the clothes.

[0020] Vertical belt rollers 12 are respectively provided in the outer tub 1 near the corners of the two longitudinal side walls 6b outside the inner tub, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com