Patents

Literature

49results about How to "Play a role in dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

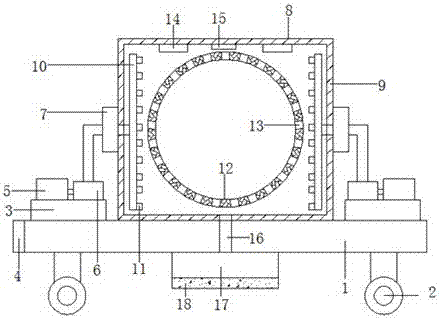

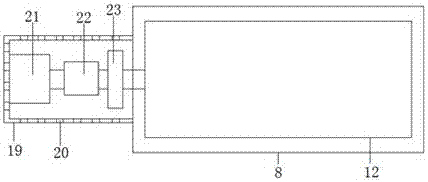

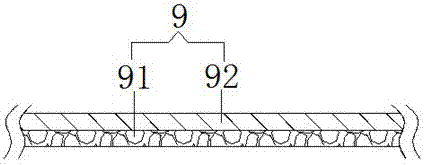

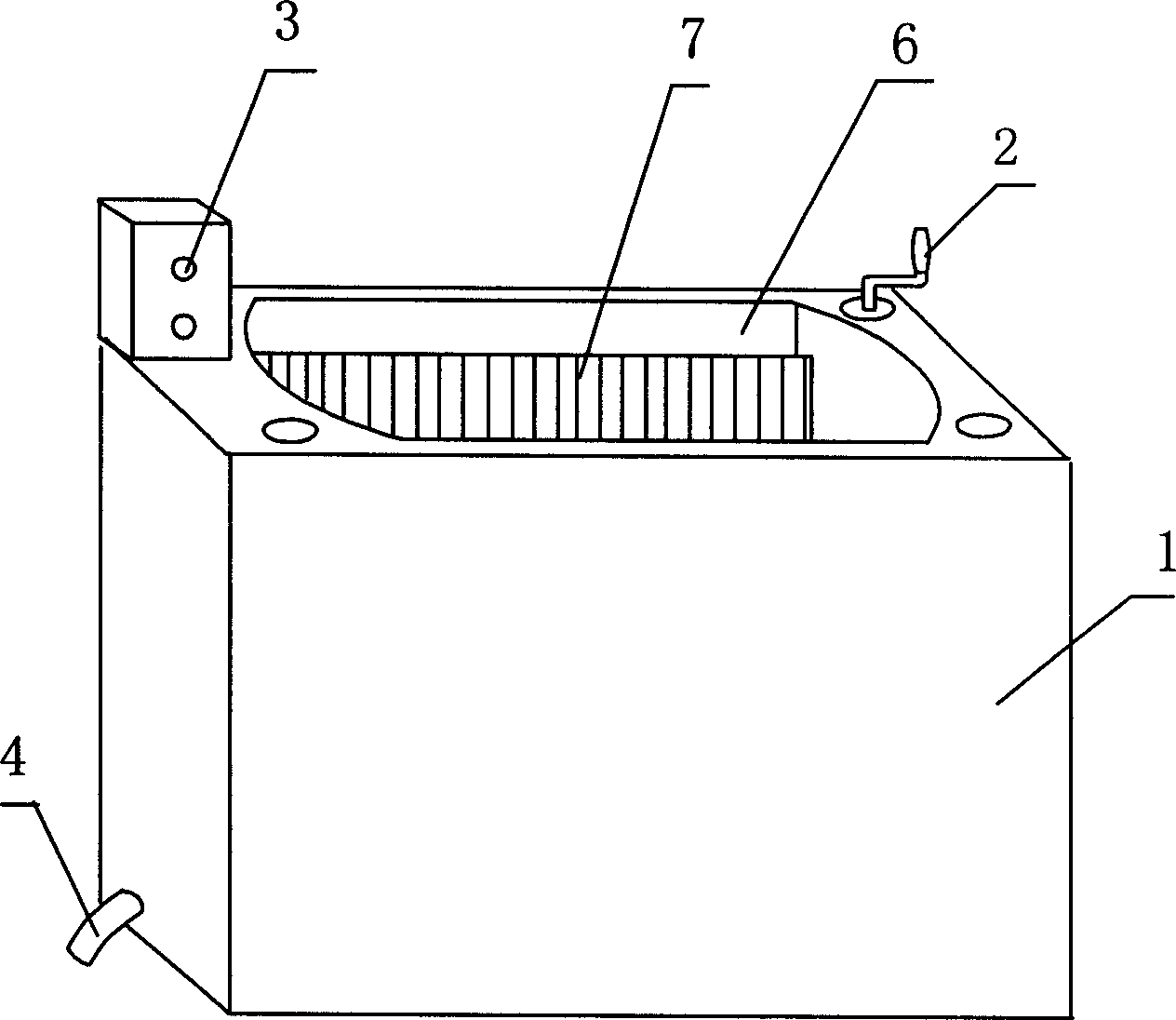

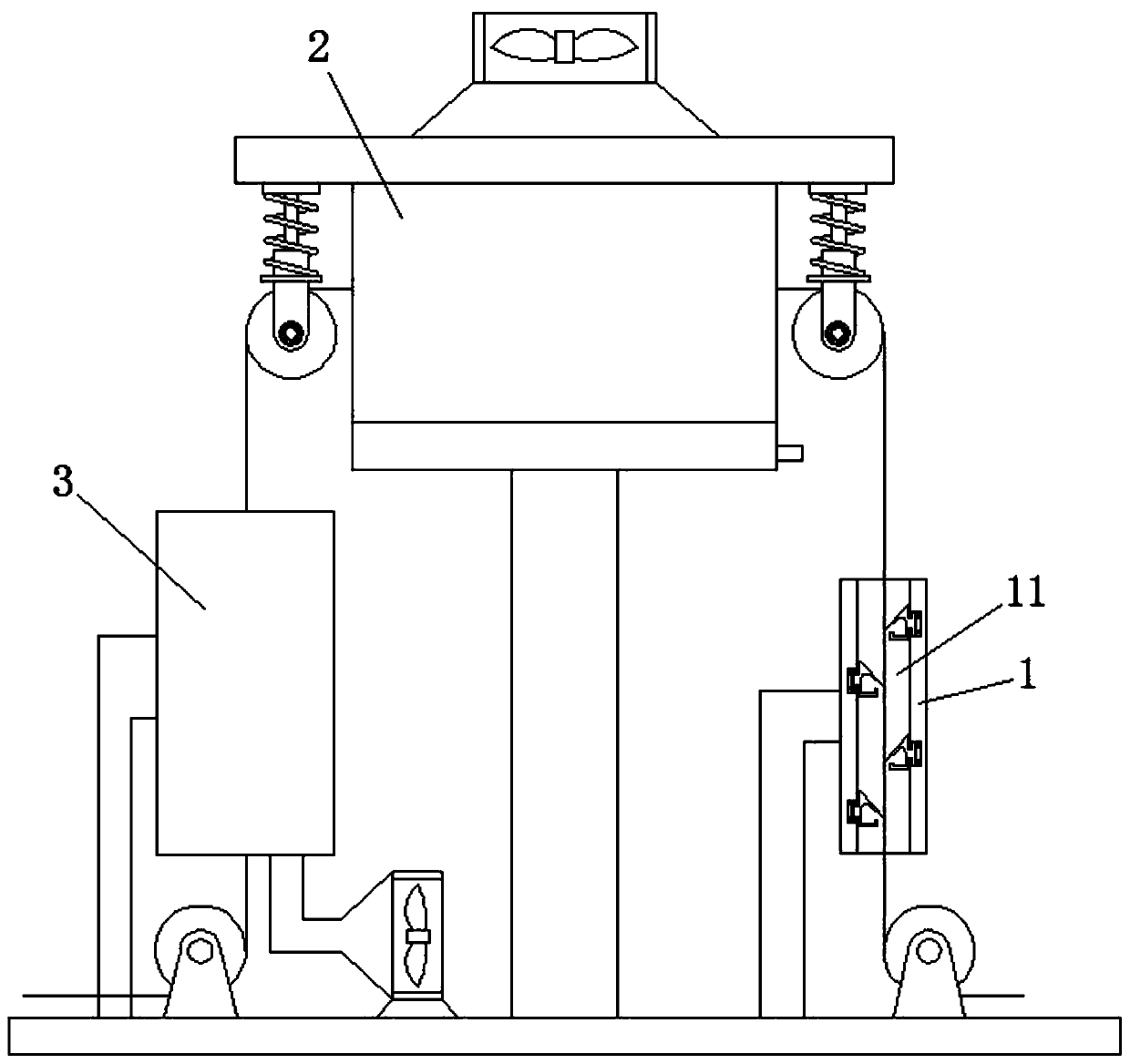

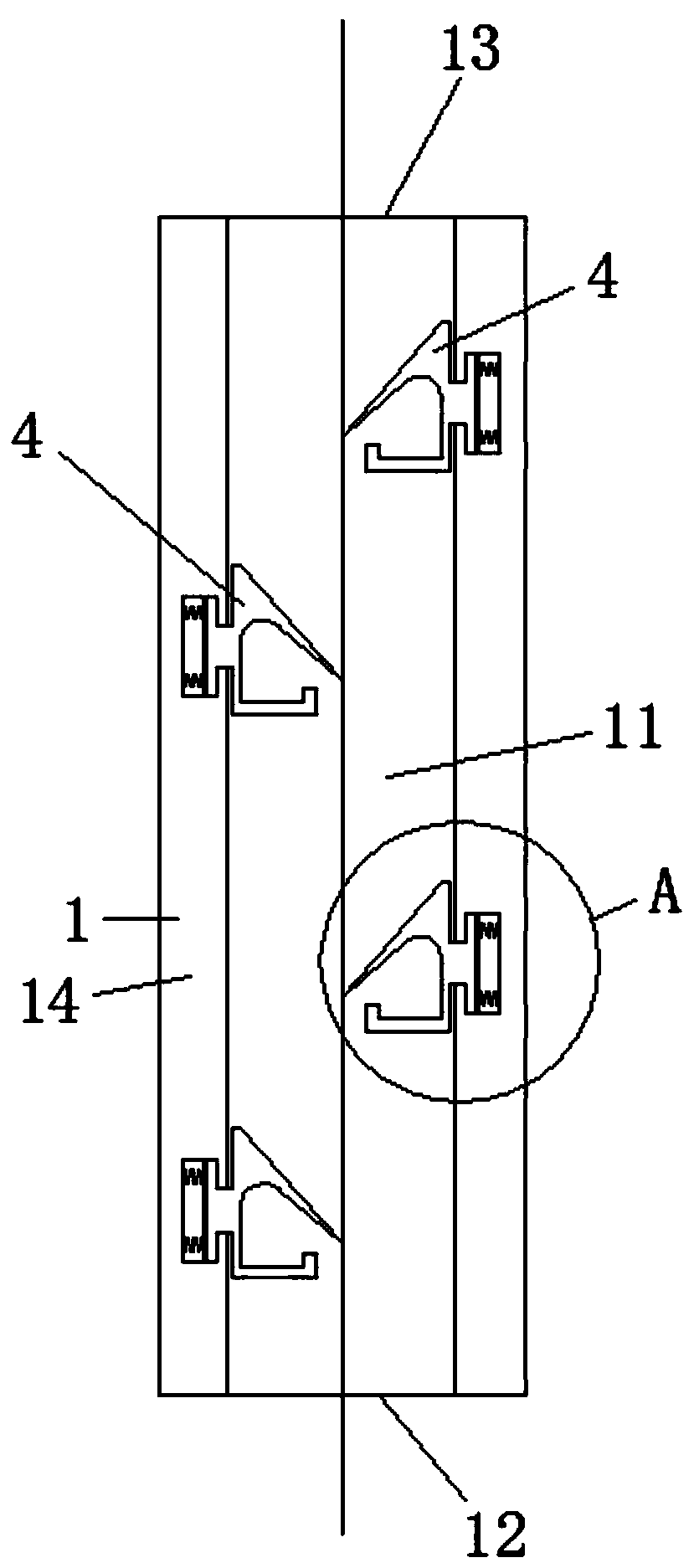

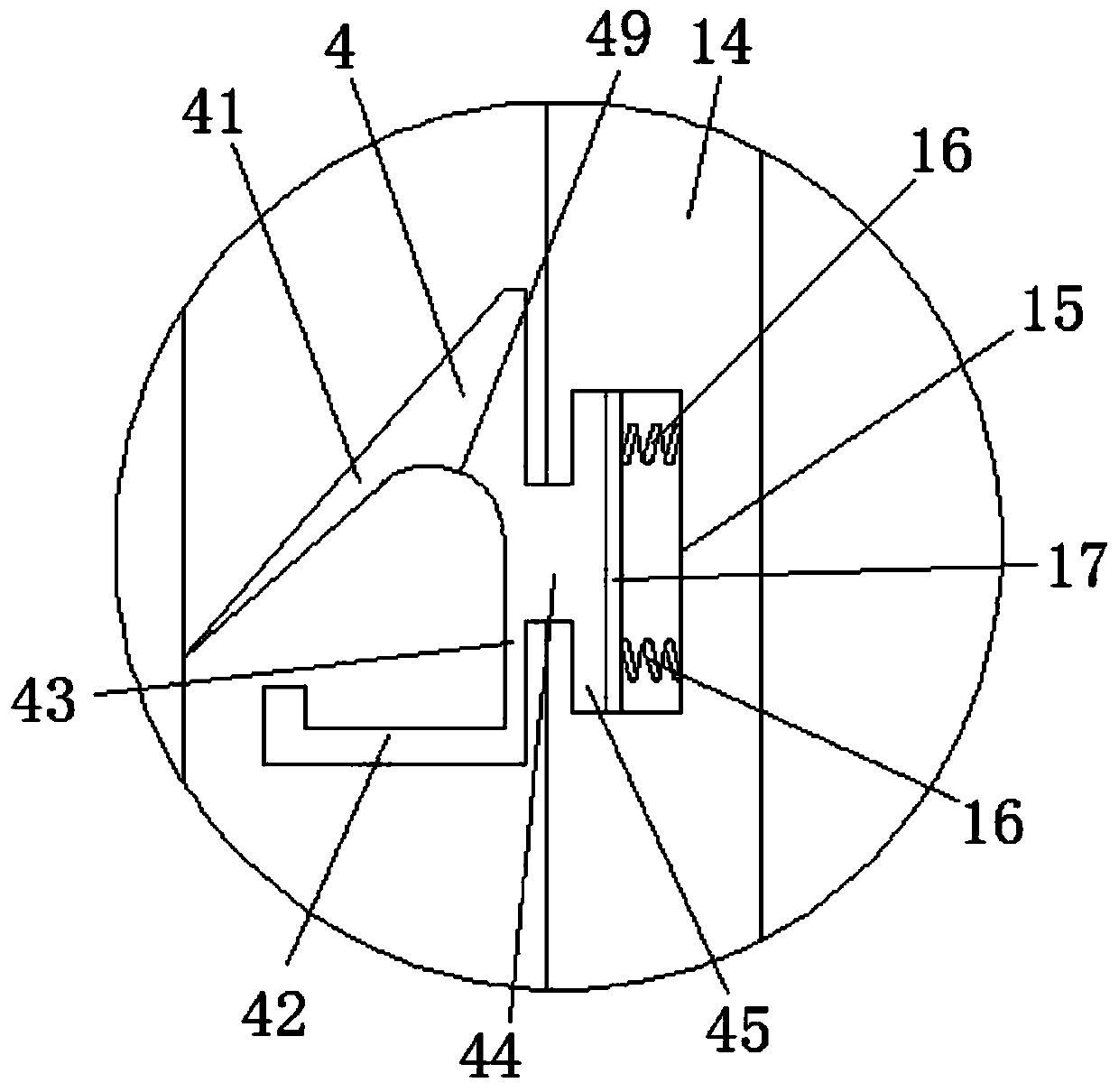

Industrial drying machine capable of drying uniformly

InactiveCN107152849AGuaranteed uptimeExtended service lifeDrying machines with non-progressive movementsDrying solid materialsElectric machineThermal insulation

The invention discloses an industrial drying machine capable of drying uniformly, and relates to the technical field of drying machines. The Industrial drying machine capable of drying uniformly comprises a base; a control device is mounted on the left side of the base; mounting seats are symmetrically arranged on the left side and the right side of the top of the base; an outer shell is mounted in the central position of the top of the base; a heat insulating layer is arranged in the inner cavity of the outer wall of the outer shell; sterilizing lamps are arranged on the left side and the right side of the top of the inner cavity of the outer shell; supporting rods are symmetrically arranged on the left side and the right side of the bottom of the mounting plate; vibration reducing grooves which are matched with the supporting rods are symmetrically formed in the left side and the right side of the top of the bottom plate; an inner cylinder is driven to rotate through a motor, and then hot air enters into and exits from the outer shell by adopting an air blower and a heating device to dry the clothes in the inner cylinder; the rotating of the inner cylinder can not only achieve a dehydrating effect, but also dry the clothes more uniformly; the base is provided with the vibration reducing grooves and springs, so that the drying machine operates more stably; and the service life of the drying machine is also prolonged.

Owner:泰州国鑫机械制造有限公司

Method for improving polyimide slurry production efficiency

The invention discloses a method for improving polyimide slurry production efficiency. The method is characterized by including the steps: adding ionic liquid into a polar solvent under protection ofnitrogen or argon to form mixed solvent; sequentially and completely dissolving a diamine monomer, a dianhydride monomer and an end capping agent in the mixed solvent; adding a catalyst to react mixture for 2-4 hours at normal temperature to obtain polyimide prepolymer slurry. The ionic liquid accounts for 0.05-1% of the weight of the polar solvent. According to the method, mixture of the polar solvent and the ionic liquid serves as a reaction medium, the ionic liquid has a catalytic function of accelerating reaction, so that a reaction process is shortened, reaction conditions are mild, the problem of cost caused by a lot of ionic liquid is improved, and economy is greatly improved.

Owner:JIANGHAN UNIVERSITY

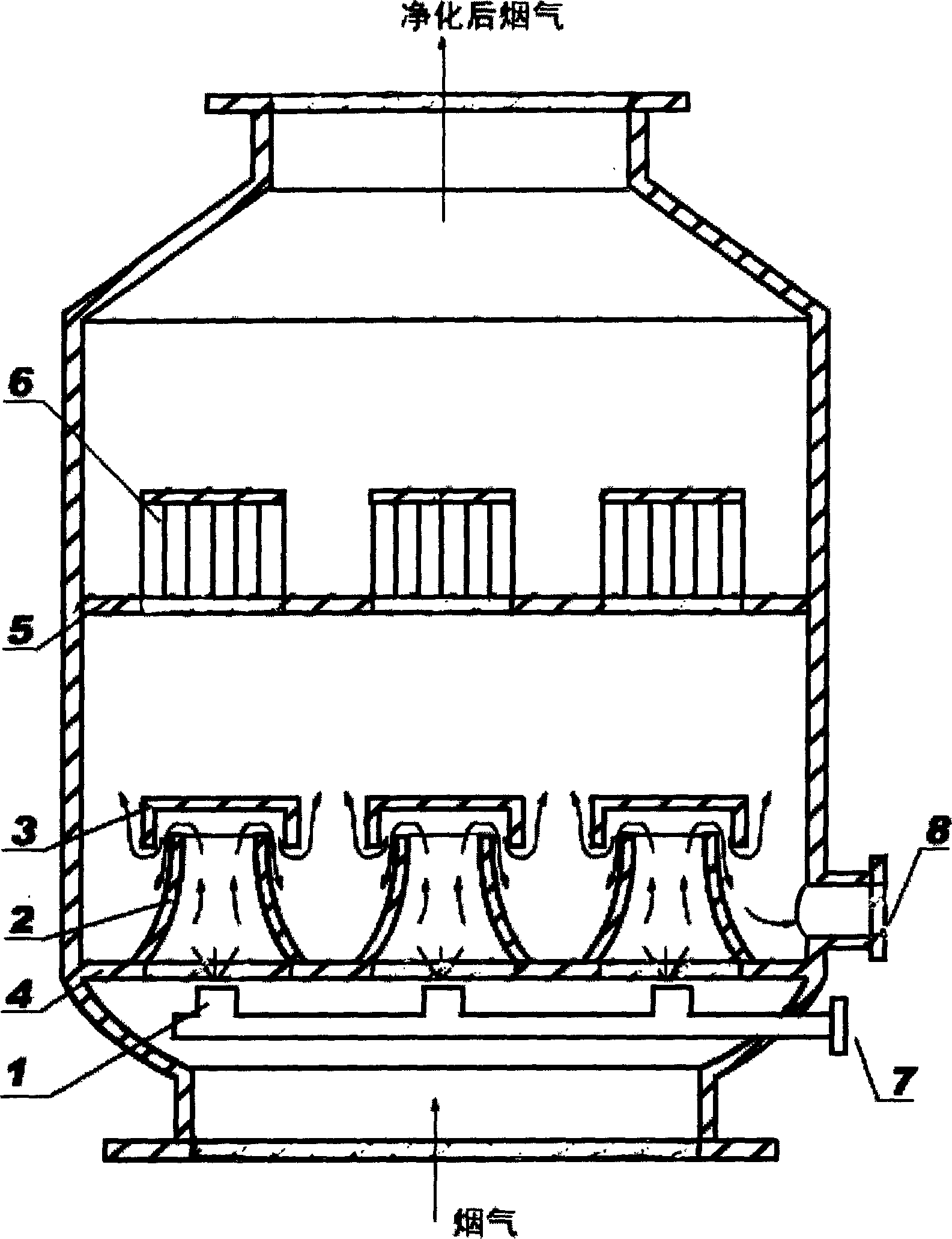

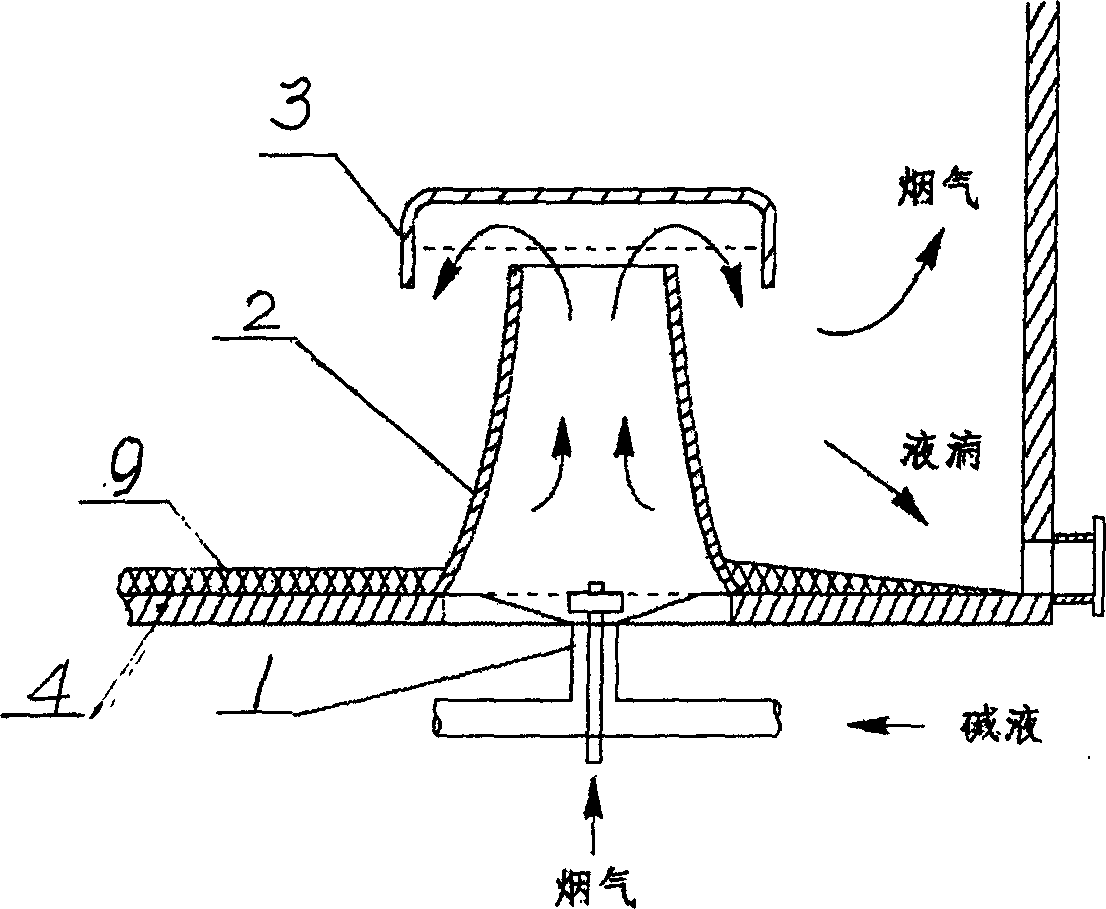

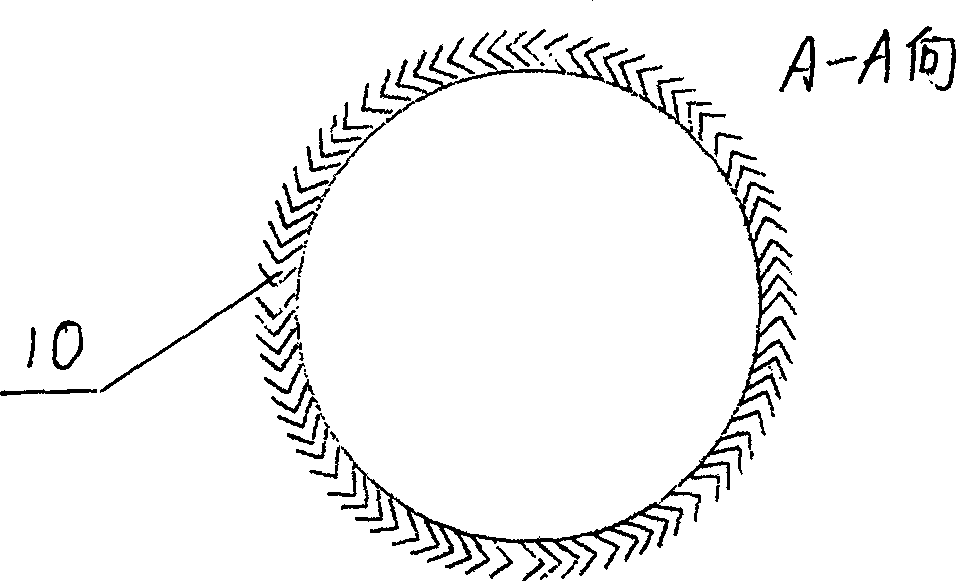

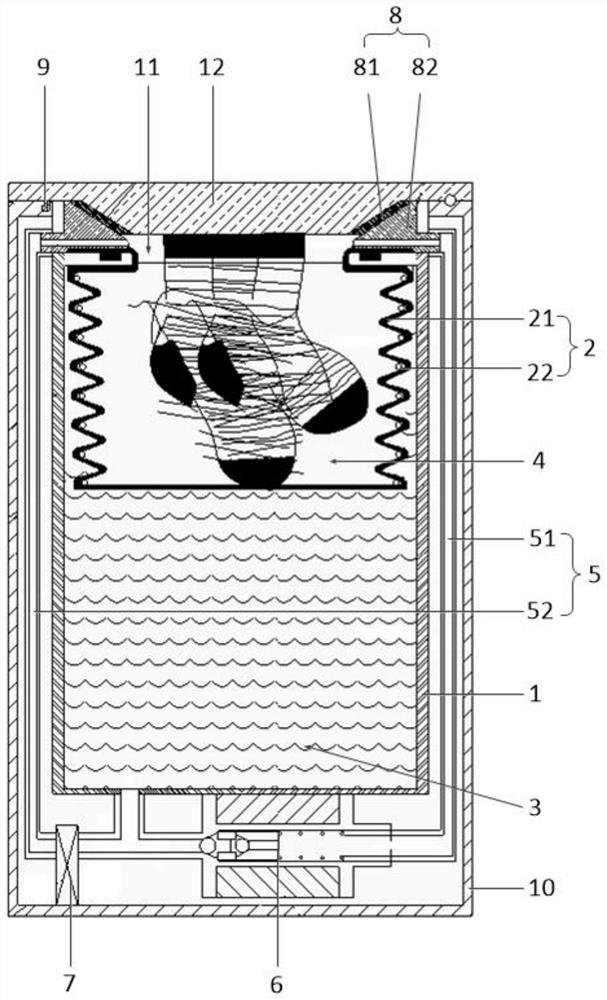

Doublestage desulfurizing and dedusting apparatus

ActiveCN1544127AMake sure you don't bring waterAvoid secondary entrainmentUsing liquid separation agentLow speedEngineering

The invention is a two-stage desulfurizing and dust-cleaning device, including a shell and a lye circulating system, and its character lies in that it is composed of low-resistance spray head, low-speed venturi tube, impact baffle and annular-arranged baffling plate demister, which are installed in turn from top to bottom. Its beneficial effect: during two-stage desulfurization circulation, adopting a low-speed venturi tube plus impact baffle structure to make the gas resistance low and desulfurizing efficiency high and play a role in primary dehydrating, and the low-resistance demister on the top of the desulfurizing tower can thoroughly eliminate fine water drops in the fume, ensuring that the fume carries no water. It is of a unit structure, convenient for installing and overhauling, the baffling plate can thoroughly dehydrate all the more because of vertical installation, avoiding secondary carrying of the fume, and it has higher flow speed and compacter device, saving the space.

Owner:北京德厚朴化工技术股份有限公司

Mechanical kneading method for clothes and kneading type washing machine

InactiveCN1730772APlay a role in dehydrationReduce consumptionOther washing machinesTextiles and paperEngineeringMechanical engineering

The present invention is mechanical clothing kneading method and kneading washer. After clothing is set inside the long and narrow washing cavity between two kneading plates, these two kneading plates are moved in opposite directions, so that the clothing is driven to rotate and washed through periodical clamping for mutual friction and releasing alternately. The kneading washer is provided with outer barrel, flat cylindrical inner barrel, belt roller connected to driver and belt. The present invention has fast washing speed, high detergency, less detergent consumption, simple structure, low cost, capacity of no-electric power running and other advantages.

Owner:罗丹

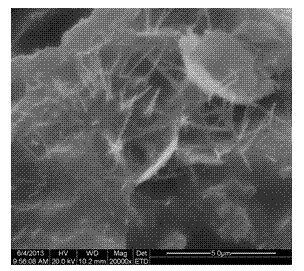

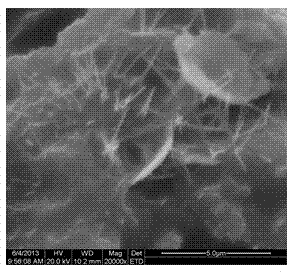

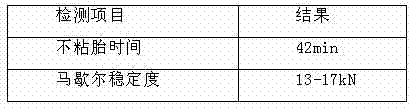

Rapid dehydration curing agent as well as preparation method and application thereof

The invention discloses a rapid dehydration curing agent as well as a preparation method and an application thereof. The rapid dehydration curing agent is formed by mixing anti-stripping agent powder, mineral powder, polymer rubber powder and cement. After the curing agent is added to a mixture, normal-temperature asphalt concrete is rapidly dehydrated and cured, and has a high elastoplastic surface layer and excellent weather resistance, so that the problems that the traditional modified emulsified asphalt concrete is slowly dehydrated and not easily cured are solved, and thus the construction efficiency and the social benefits are greatly improved.

Owner:南通福伦利新材料有限公司

Preparation method of chromium-free leather

ActiveCN109234477AReduce processShorten the production cycleTanning treatmentPre-tanning chemical treatmentFiberChromium free

The invention discloses a preparation method of chromium-free leather. Firstly naked leather is dehydrated by adopting an organic solvent 1 till the water content is lower than 10%, white wet leatheris obtained, and the organic solvent is recycled; an organic solvent 2 with the tare weight being 30-200% and a reactive substance with the tare weight being 2-20% are added and rotated for 120-600 minutes, and bath liquid is recycled; and finally drying is conducted, and dyeing and filling operations can be done before drying. The white wet leather is prepared through dehydration by adopting thesolvent, then the reactive substance is added to react with the hydrophilic group on the collagenous fiber, the hydrophilic group is blocked, the waterproof performance is improved, accordingly the leather with fiber dispersed is sufficiently and durably fixed, and preparation of the chromium-free leather is finally achieved. The preparation method is characterized in that the production period isshort, the procedure is simple and easy to operate, the prepared leather has the good softness, good gas permeability and high tension stress.

Owner:SICHUAN UNIV

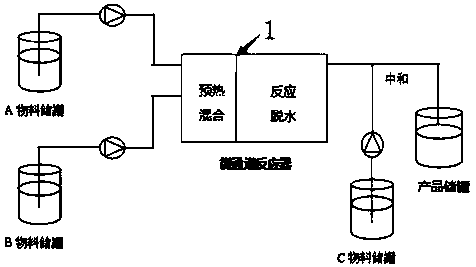

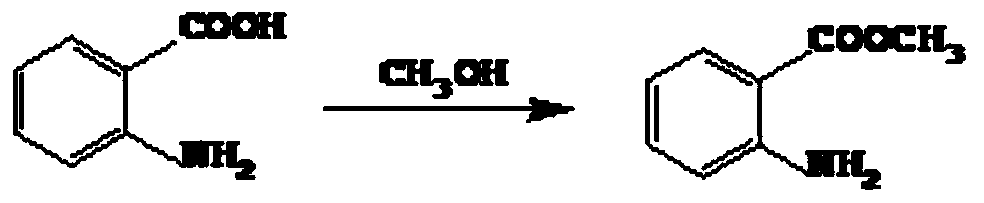

Method for continuously preparing methyl anthranilate

InactiveCN110229077AHigh purityHigh yieldOrganic compound preparationChemical/physical/physico-chemical microreactorsMethyl anthranilateSolvent

The invention provides a method for continuously preparing methyl anthranilate, belonging to the technical field of preparation processes for organic compounds. The method comprises the following concrete steps: separately pouring a methanol solution of anthranilic acid and a concentrated sulfuric acid solution into a mixed reaction chamber of a microchannel reactor, and carrying out a preheatingreaction in the mixed reaction chamber to form a mixed solution having methyl anthranilate; and neutralizing a sodium hydroxide solution and the mixed solution, and carrying out cooling to allow methyl anthranilate to be precipitated. According to the invention, the methanol solution of anthranilic acid and concentrated sulfuric acid are separately injected into the mixed reaction chamber of the microchannel reactor; the concentrated sulfuric acid produces dehydration and catalysis effects and can promote the reaction of anthranilic acid with methanol to form methyl anthranilate, so the product can be obtained in one step without a solvent reaction, no additional post-treatment procedure is needed, and environment protection is realized; the concentrated sulfuric acid solution can be neutralized by the sodium hydroxide solution, which is beneficial for improving the purity and yield of methyl anthranilate, and product synthesis efficiency is high.

Owner:SHENZHEN E ZHENG TECH

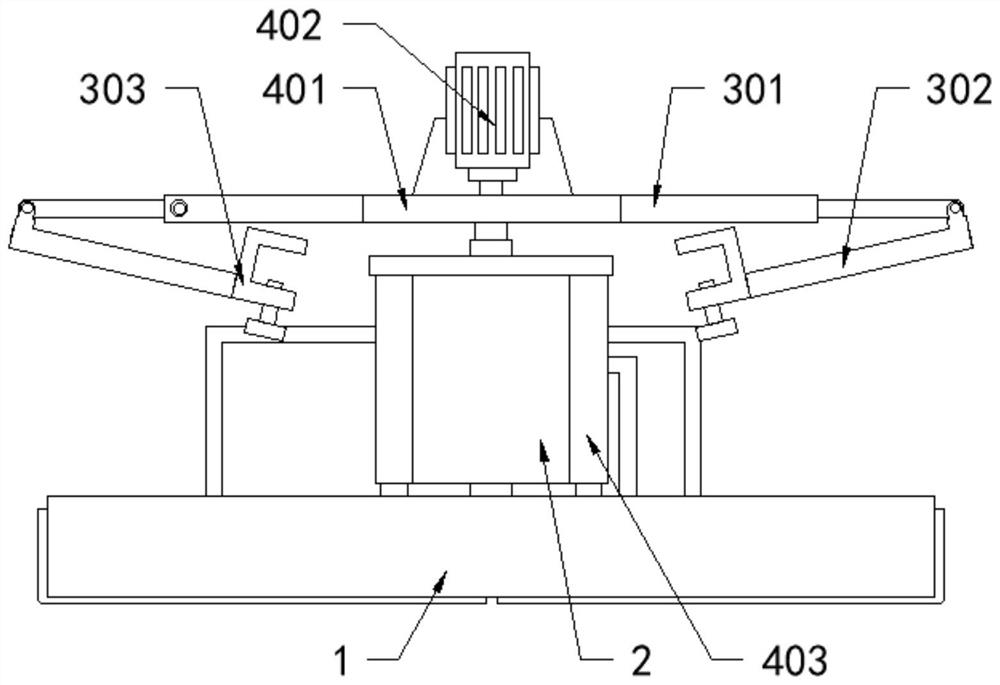

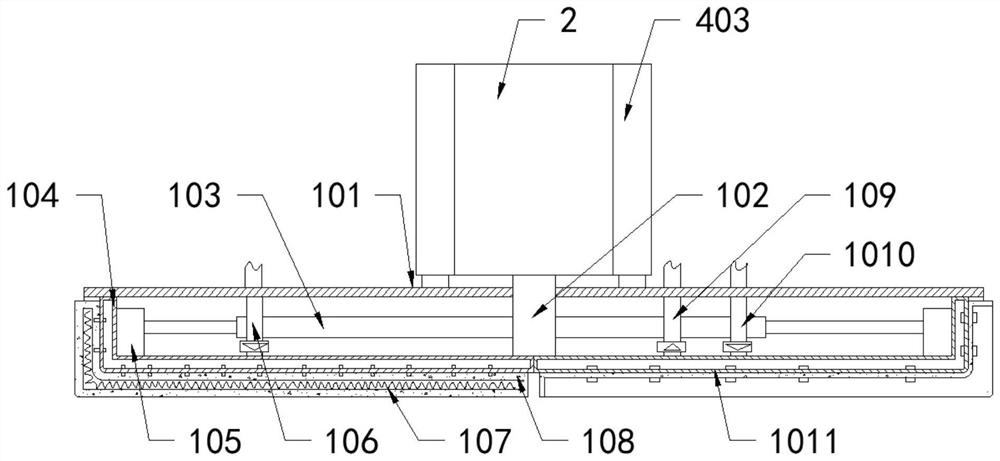

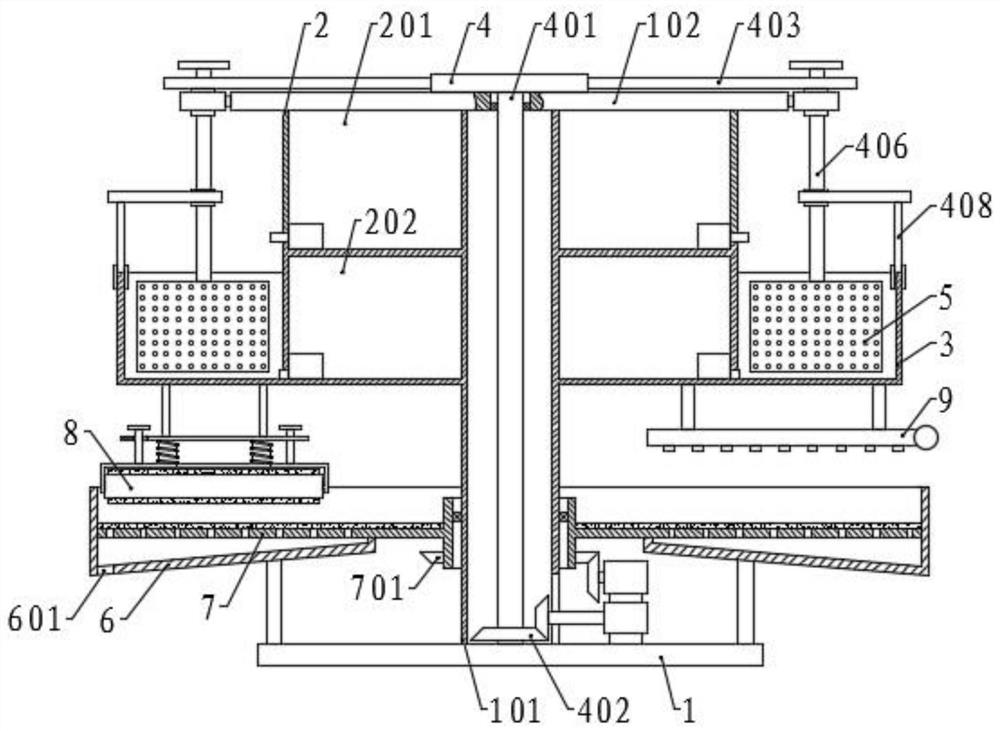

Concentrating, dewatering and strong-pressure integrated sludge dewatering machine

ActiveCN110734205AReduce moisture contentPlay a role in dehydrationSludge treatmentWater filterProcess engineering

The invention discloses a concentrating, dewatering and strong-pressing integrated sludge dewatering machine which comprises a rack, and further comprises a gravity filtering mechanism, a vertical rolling dewatering mechanism and a counter-pressing type dewatering mechanism which are sequentially arranged on the rack, the gravity filtering mechanism comprises a filtering device, a bottom frame assembly, a side leakage preventing assembly, a mud overturning assembly and a thickness adjusting assembly; the vertical rolling dehydration mechanism comprises an S-shaped dehydration section, the S-shaped dehydration section is located at the downstream of a slurry outlet, the S-shaped dehydration section comprises a plurality of dehydration rollers which are rotatably connected to the rack and are integrally arranged from bottom to top, and the outer diameters of the dehydration rollers are gradually decreased to the minimum outer diameter from the upstream to the downstream; the counter-pressing type dewatering mechanism comprises a strong pressing section, a strong pressing roller set is arranged on the strong pressing section, and the strong pressing roller set comprises a fixed rollerset and a movable roller set. The gravity filtering mechanism, the vertical rolling dewatering mechanism and the counter-pressure type dewatering mechanism are arranged to form the sludge dewateringmachine which is large in treatment flux, high in water filtering capacity and high in treatment precision.

Owner:FOSHAN UNIVERSITY

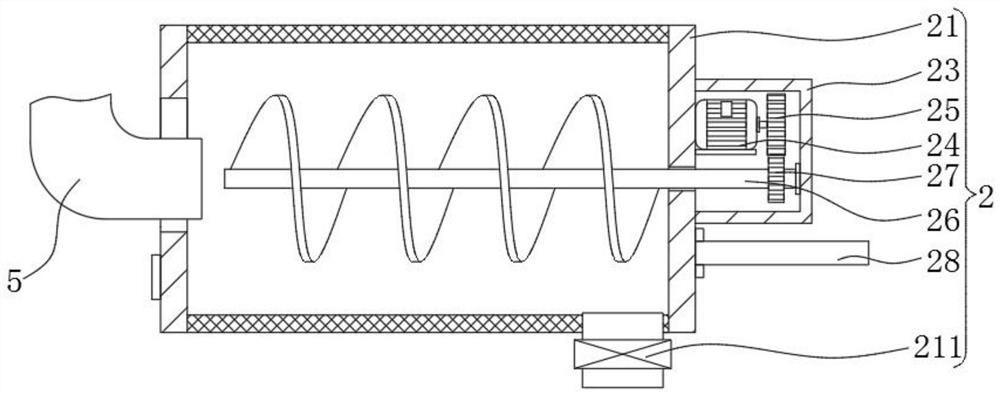

Dehydration and drying device for scutcher

ActiveCN111501261ALevelingPlay a role in dehydrationMechanical cleaningTextile treatment containersChemistryForeign matter

The invention discloses a dehydration and drying device for a scutcher. The dehydration and drying device comprises a cleaning device, a dehydration device and a drying device which are arranged in sequence, and then integration of scutching, dehydration and drying can be achieved. When fabric passes through the cleaning device, a cleaning scraper blade on the cleaning device is in contact with the two sides of the fabric, uncleaned naps and foreign matter of the fabric can be scraped off, and meanwhile, certain effects of smoothing and dehydration on the fabric can be achieved. When the conveyed fabric passes through the dehydration device, a beating roller rotates to make a beating strip beat and dehydrate the upper and lower sides of the fabric, and the fabric is unlikely to get wrinkled. A drying box is arranged longitudinally, a cloth outlet seam for the fabric to penetrate through is formed in a cover plate of the drying box, through a small fabric outlet, the amount of water vapor leaking to the fabric outlet can be reduced, and the influence of the water vapor on the dried fabric is prevented; and meanwhile, air current generated by a second draught fan is input to the drying box from bottom to top, then generated hot gas is discharged to an inlet, and the influence of hot steam on the dried fabric is reduced.

Owner:浙江嘉业印染有限公司

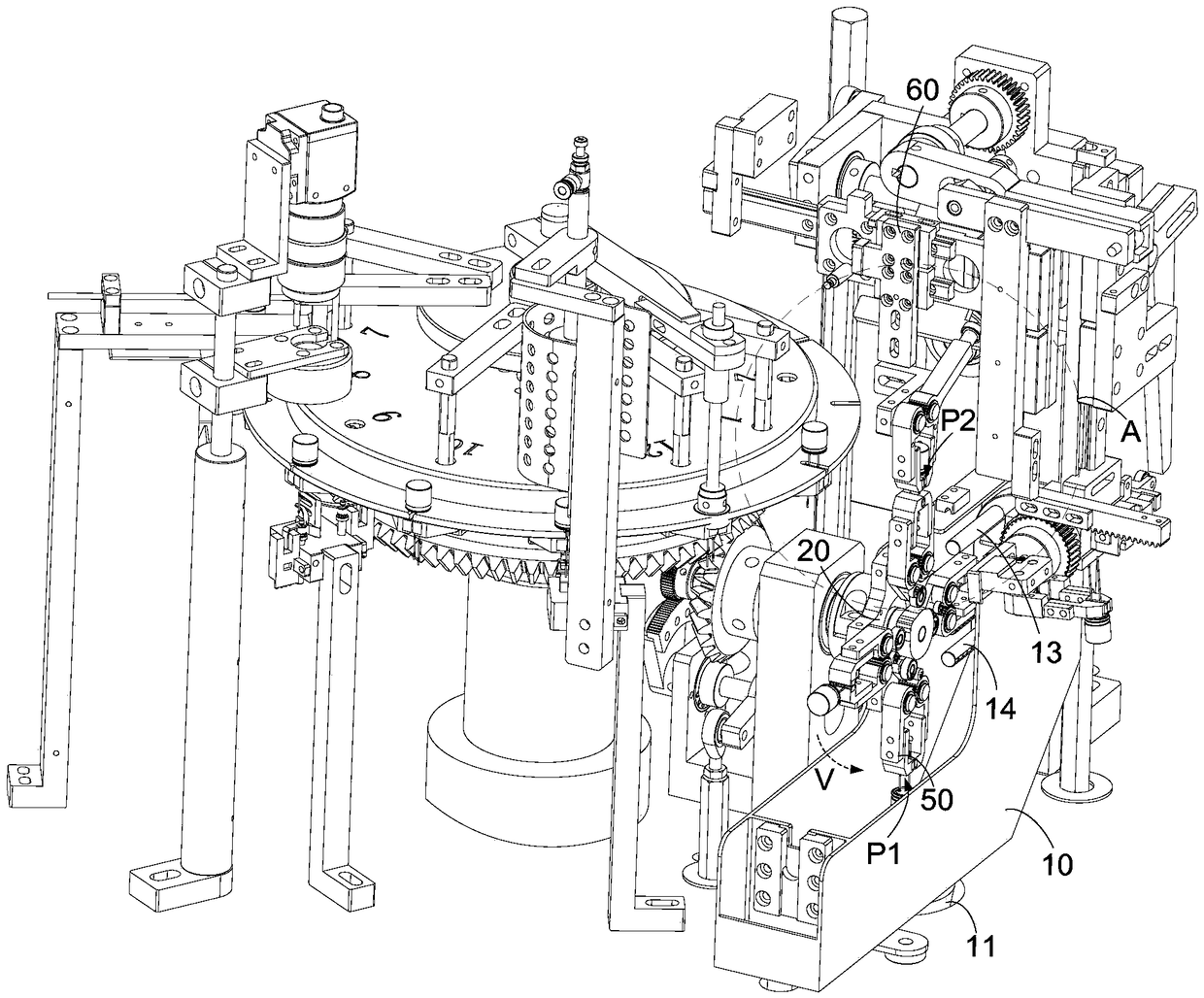

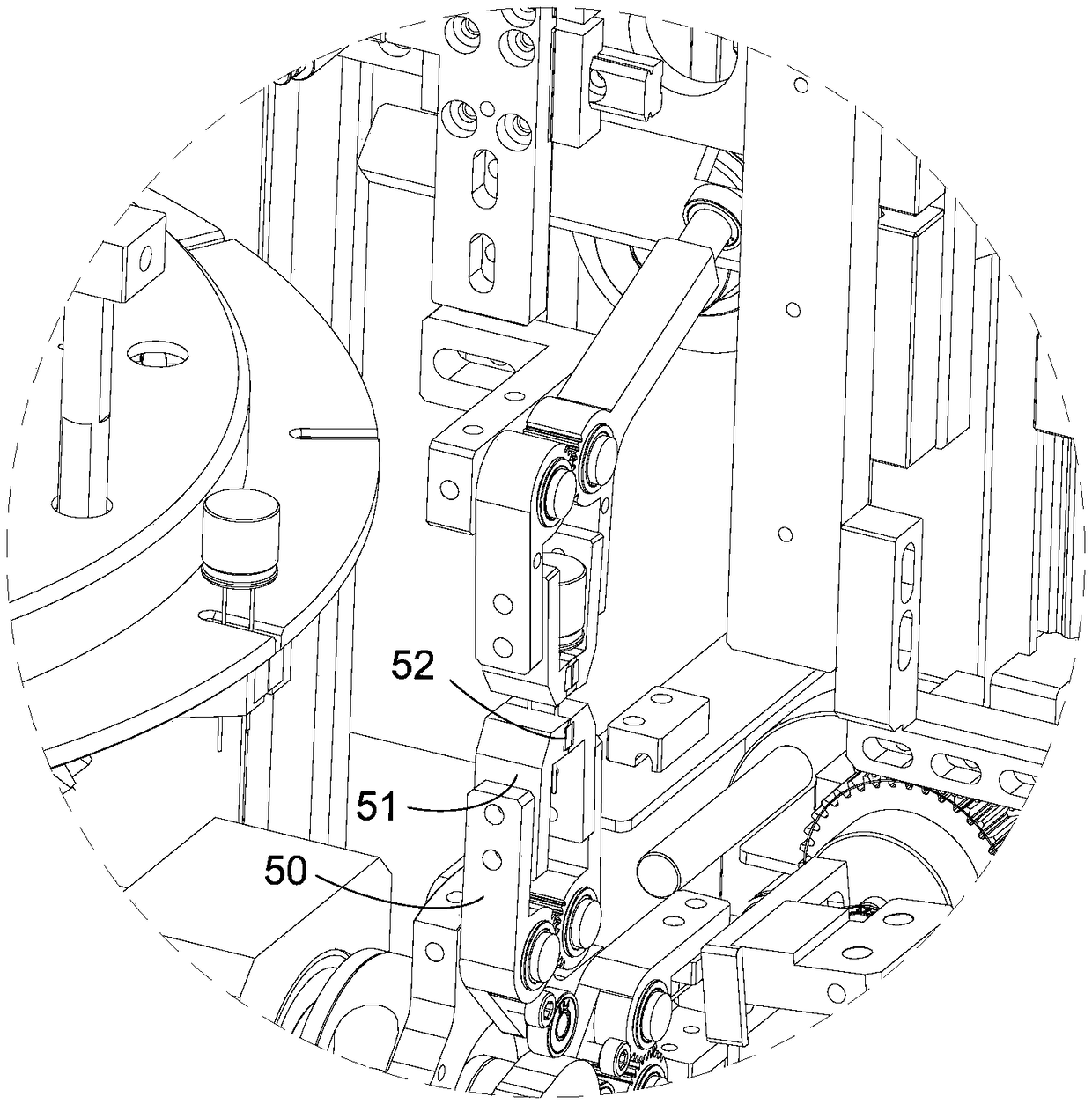

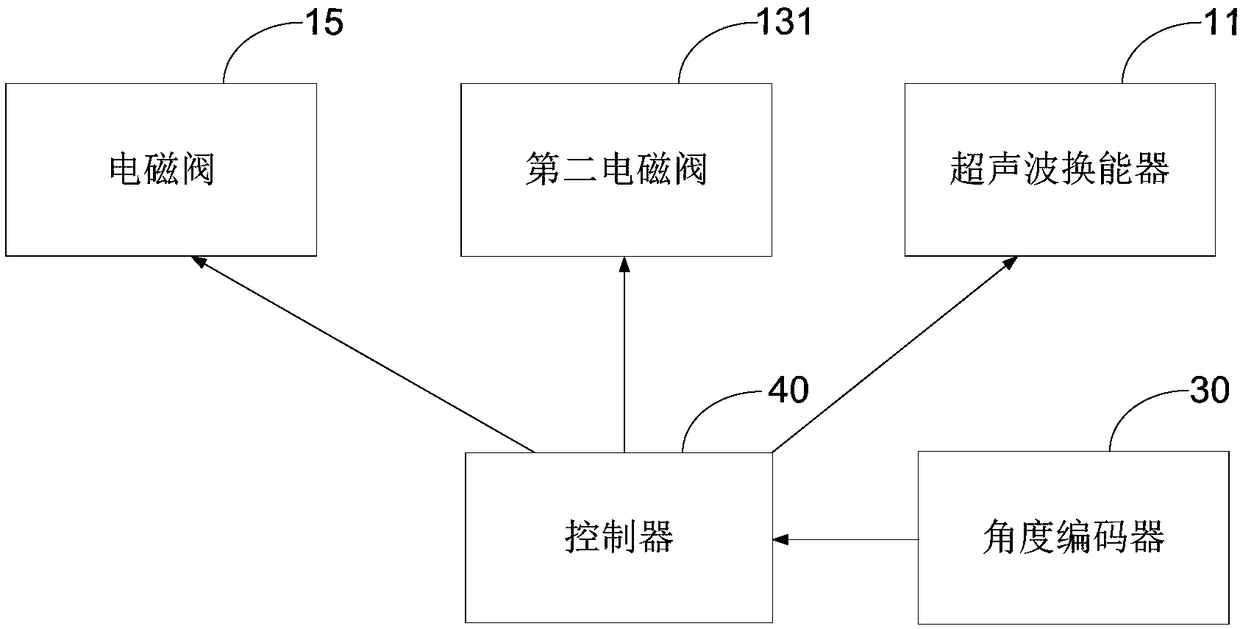

Cleaning device and capacitor group vertical printing integrated machine

InactiveCN109414735APlay a role in dehydrationExtension of timeDrying gas arrangementsCleaning using gasesCapacitanceCleaning station

The application discloses a cleaning device and a capacitor group vertical printing integrated machine. The cleaning device is used for cleaning a capacitor blank, and the cleaning device comprises afirst washer, a rotating frame, an angle encoder and a controller. The first cleaner is used for wet cleaning the naked product of the cleaning station and is provided with a second cleaner. The second cleaner is used to dry clean the naked product of the cleaning station. The rotating frame is rotated around its rotation axis to clamp the naked product alternately into and out of the cleaning station. The angle encoder is used to encode according to the rotation angle of the rotating frame. The controller is respectively connected to the angle encoder and the first cleaner for controlling thefirst cleaner to wet the naked product according to the signal of the angle encoder. The technical solution of the present application can improve the yield of capacitor manufacturing.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

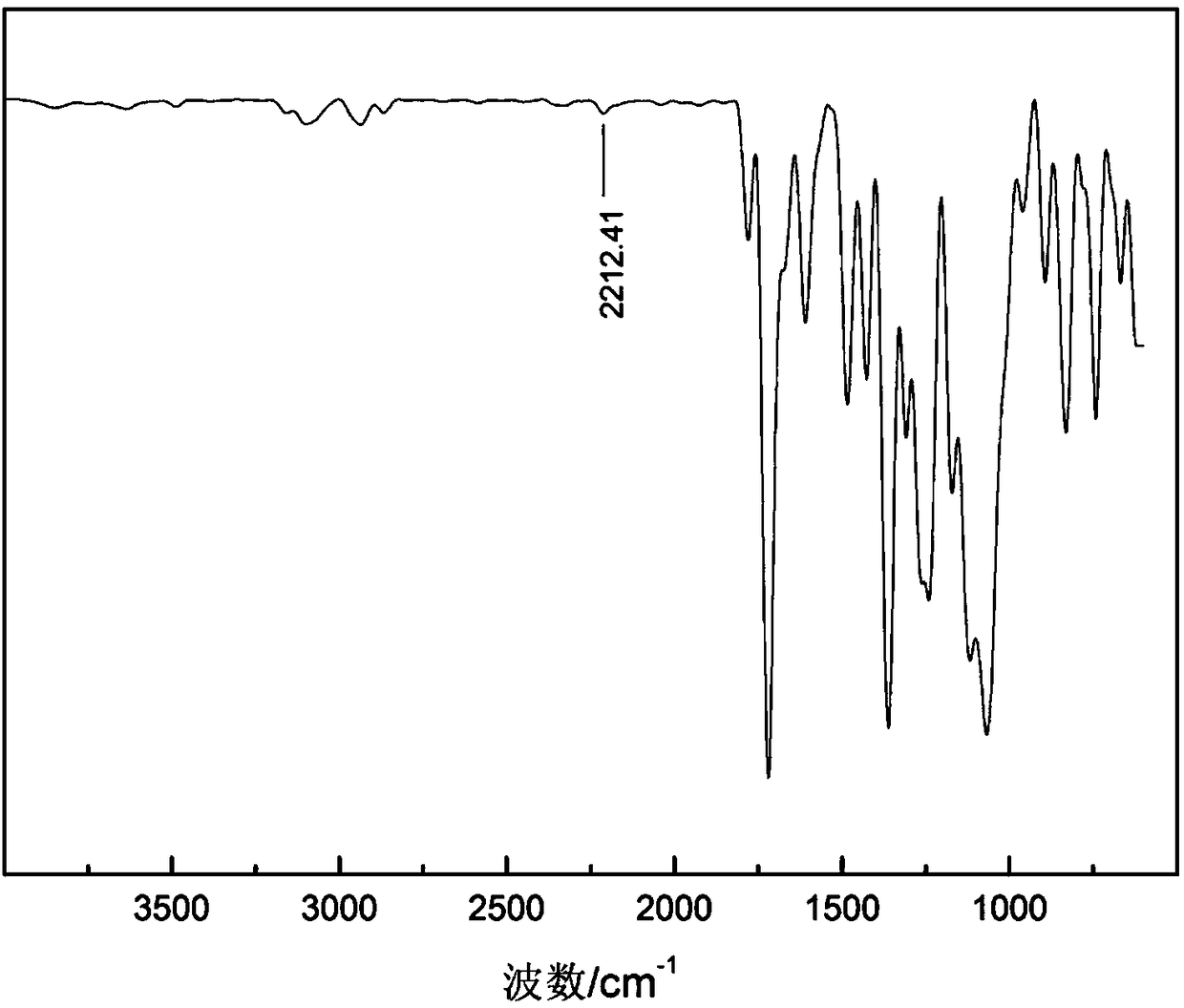

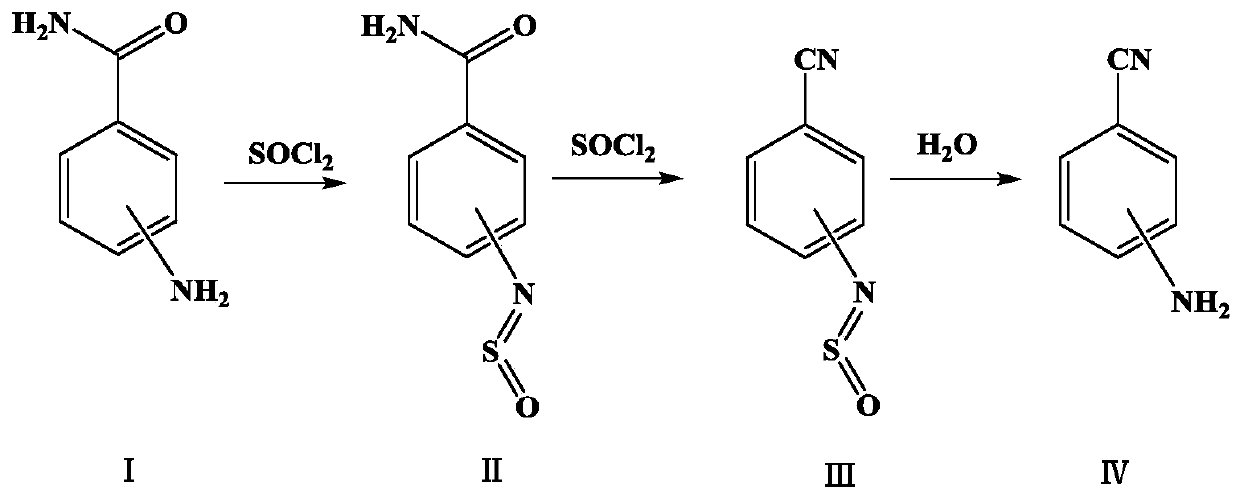

Preparation method of aminobenzonitrile

PendingCN111269144APlay the role of protecting the amino groupPlay a role in dehydrationOrganic compound preparationCarboxylic acid amides preparationReaction temperatureHydrolysis

The invention relates to the technical field of fine chemical synthesis, and discloses a preparation method of aminobenzonitrile. Aminobenzamide is taken as a raw material, and aminobenzonitrile is obtained through a three-step reaction of amino protection, dehydration and hydrolysis by taking thionyl chloride as an amino protective agent and a dehydrating agent, The preparation method comprises the following steps: amino protection and dehydration are carried out on aminobenzamide by thionyl chloride in sequence to obtain an amino-protected nitrile organic matter, then water is added to carryout a hydrolysis reaction, and the protective agent on the amino group is removed to obtain the aminobenzonitrile product. The thionyl chloride is used, so the dehydration effect can be achieved, anda new group formed by a reaction of the thionyl chloride with the amino group can play a role in protecting the amino group in the reaction process, thereby the product yield and quality are obviously improved, the reaction temperature is greatly lower than that of a traditional process, the reaction time is obviously shortened, the safety is obviously improved, the operation is simple, the conditions are mild, the method is green and clean, aminobenzonitrile can be efficiently prepared at low cost, and the method is suitable for industrial production.

Owner:新乡市锦源化工有限公司

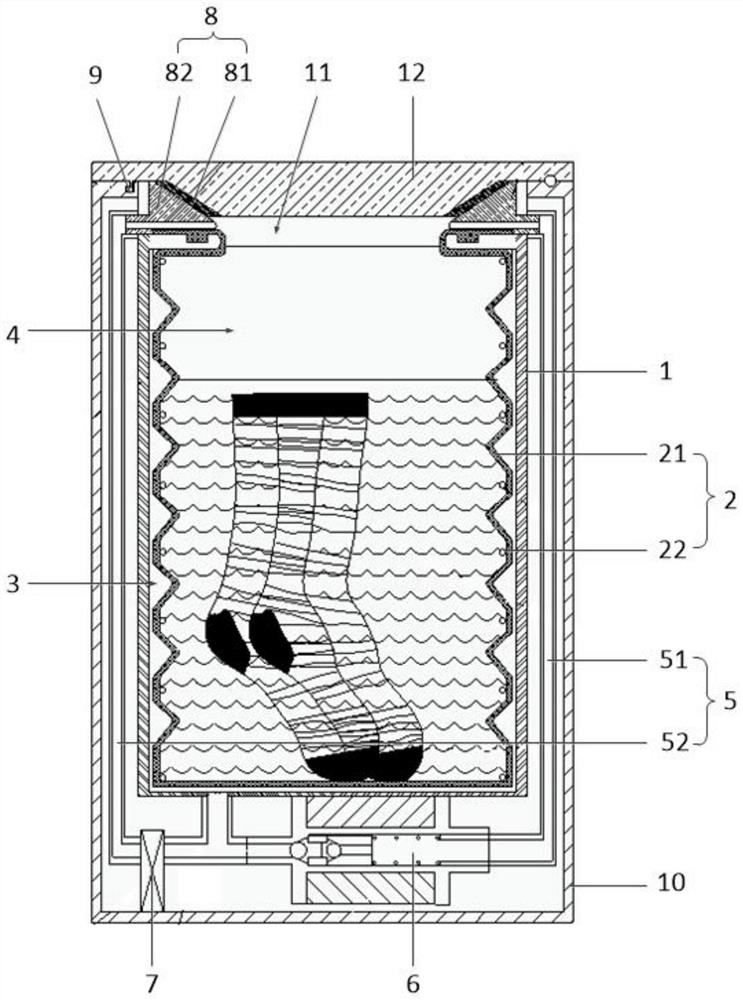

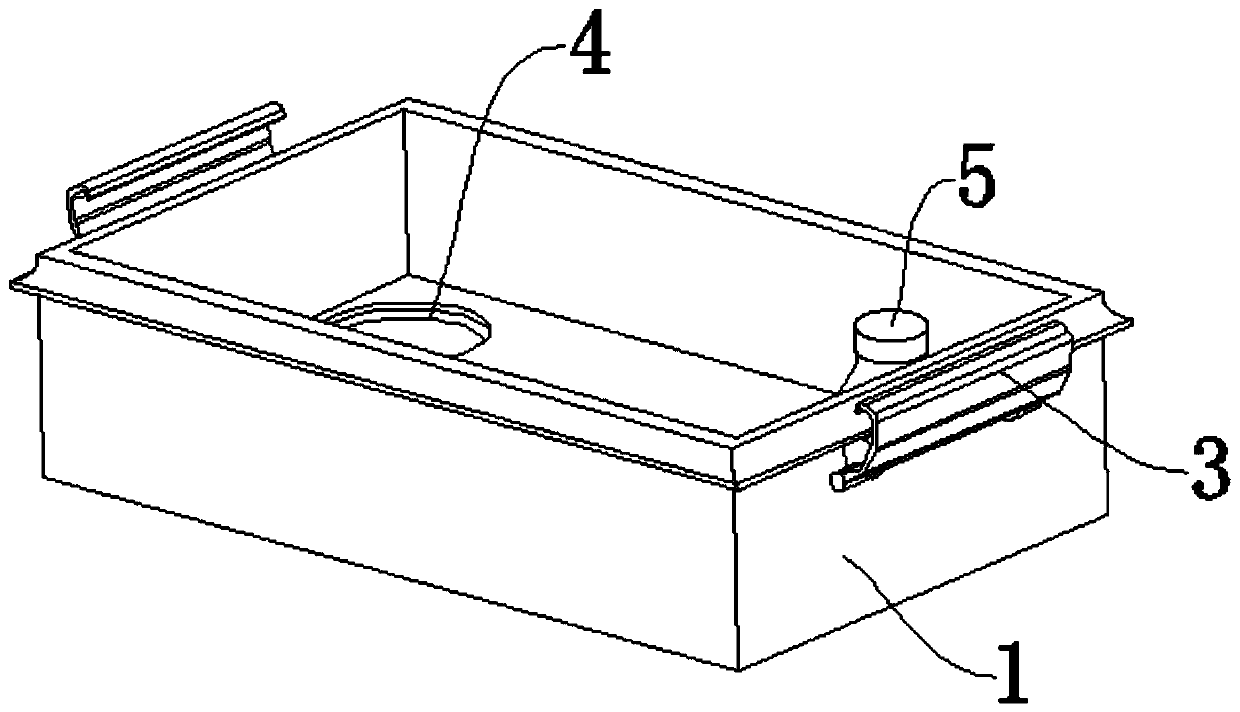

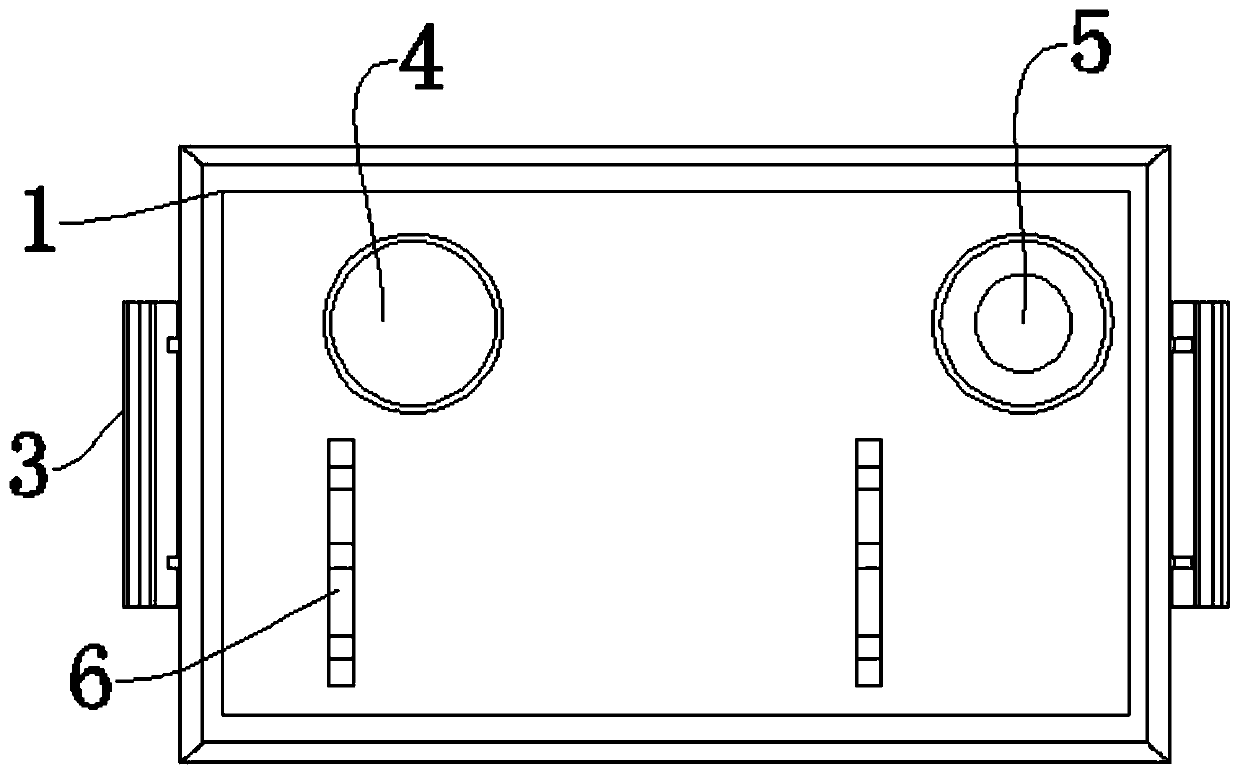

Miniature clothes treatment equipment

ActiveCN113944025ASmall footprintReduce weightOther washing machinesTextiles and paperMechanical engineeringIndustrial engineering

The invention belongs to the technical field of clothes treatment, and particularly provides miniature clothes treatment equipment. The invention aims to solve the problem that existing socks and other small articles are inconvenient to wash by a machine. In order to achieve the purpose, the miniature clothes treatment equipment comprises a first shell and a springback cavity; the springback cavity is formed in the inner side of the first shell; a cavity between the springback cavity and the first shell is a first cavity; a cavity in the inner side of the springback cavity is a second cavity; a clothes putting opening is formed in the first shell; a sealing cover covers the clothes putting opening; the clothes putting opening penetrates through the first cavity through a putting channel and then is communicated with the second cavity; the first cavity and the second cavity are communicated through a backflow pipe; and a one-way drainage device is further arranged in the backflow pipe. By means of the arrangement mode, water and electricity can be saved, the clothes treatment equipment is small, light, convenient to carry, high in working efficiency, few in component and simple in structure, and the production cost can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

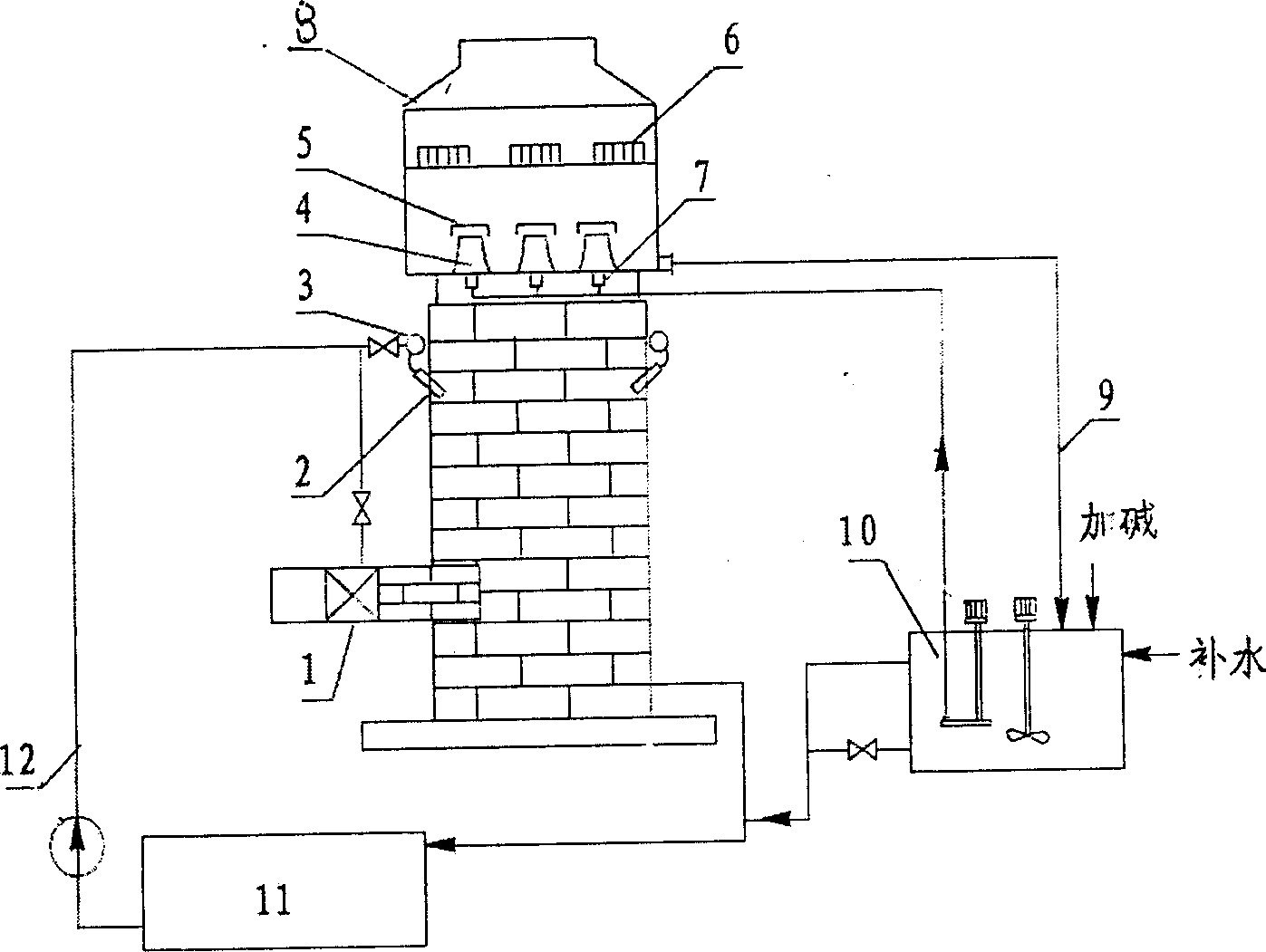

Dual cycle pocked stone pagoda stack gas desulfurizing and dedusting apparatus

The invention is a double-circulating granite tower fume -desulfurizing and -dust cleaning device, including granite tower main body, solution distributor, dust-water circulating system and sedimentation tank. Its character: there is an annular wetting sprayer in the inlet channel of the granite tower; the solution distributor is composed of many pipes extending into the granite tower and uniformly distributed along the circumference on the granite tower main body and near the top; the top of the granite tower main body is also installed with a two-stage desulfurizing and dust-cleaning device. Its beneficial effect: adopting a double-circulating system, i.e. the dust-water and alkali liquor independently circulate, respectively, thus enhancing the alkali utilization ratio and making the desulfurizing and dust-cleaning course stable and the desulfurizing and dust-cleaning efficiency high. The two-stage desulfurizing circulation has high desulfurizing efficiency and plays a role in primary dehydrating, and the low-resistance demister on the top of the desulfurizing tower can thoroughly eliminate fine water drops in the fume, ensuring that the fume carries no water. Adopting solution distributing pipes to replace solution distributing tanks can use samller water quantity to form a uniform falling liquid film on the inner wall of the dust-cleaning tower, ensuring dust-cleaning efficiency and avoiding dust accumulating.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Sludge dewatering drying method

InactiveCN102976585AGood deodorizing effectReduce pollutionSludge treatment by de-watering/drying/thickeningCoalPotassium permanganate

The invention belongs to the environment engineering field, and specifically relates to a method for dewatering drying sludge after sewage treatment. The method comprises the following steps of adding coal ash and quick lime in the sludge; stirring; heating the above materials or introducing heat wind to the above materials; controlling the temperature of the sludge to be 50-80 DEG C; and at the same time, stirring for 10-30 minutes; adding ferric chloride and potassium permanganate to the above materials for hardening and tempering, wherein the additional amount of ferric chloride is 0.1-1% by mass of the weight of the sludge, and the additional amount of potassium permanganate is 0.05-1% by mass of the weight of the sludge; heating the above materials or introducing the heat wind to the above materials; controlling the temperature of the sludge to be 50-80 DEG C; and at the same time, stirring for 10-20 minutes. The method is low in cost and simple in process.

Owner:慈溪市沿途户外用品有限公司

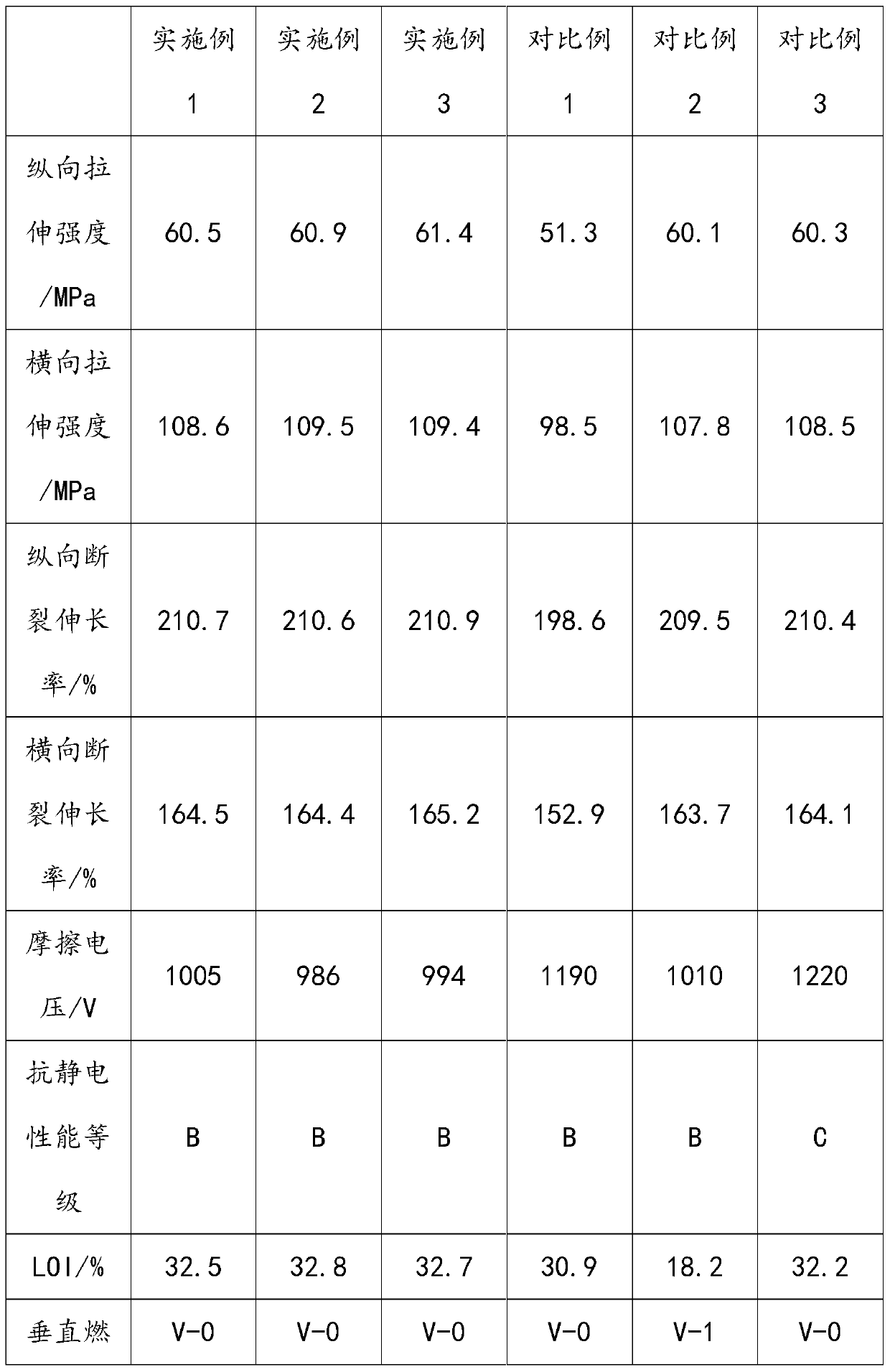

Preparation technology of anti-static and flame-retardant non-woven fabric

PendingCN111235667AImprove mechanical propertiesImprove antistatic performanceElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolymer scienceSpinning

The present invention discloses a preparation technology of an anti-static and flame-retardant non-woven fabric. The preparation technology comprises the following steps of 1, performing vacuum dryingon raw materials at 80 DEG C overnight, and putting the raw materials into a mixer for mixing; 2, putting a mixed material into a melt-blowing spinning machine for spinning the mixed material into apolypropylene non-woven fabric; and 3, preparing 1,4-butylene glycol, benzophenone and absolute ethanol into a solution, soaking the non-woven fabric in the solution, performing ultraviolet lamp irradiation, and performing cleaning. The non-woven fabric takes PP resin as a non-woven fabric base material, and by adding a reinforcing filler into the base material, the mechanical performance and theantistatic performance of the non-woven fabric are enhanced; by adding a flame retardant into the base material, a synthesized flame retardant not only has good compatibility with a PP base, but alsocan enable the non-woven fabric to achieve the excellent flame-retardant effect; and the reinforcing filler and the flame retardant are directly blended with the PP resin, are different from finishingof finishing liquid, difficultly fall and lose effect, and have durable antistatic performance and flame retardant performance.

Owner:新昌县丙辰储能科技有限公司

Production method and product of multifunctional lightweight sludge concrete

The invention belongs to the technical field of concrete products and particularly relates to a production method and a product of multifunctional lightweight sludge concrete. According to the method, sludge produced through sewage treatment reacts with quicklime firstly, and sludge slaked lime is formed; the sludge slaked lime is then mixed with cement and water, and the lightweight sludge concrete is formed. The production method cannot cause environmental pollution, is low in cost and can solve the problem about sludge treatment in the sewage treatment industry, the lightweight concrete with multiple purposes can be produced through recovery and utilization of the sludge, and the sludge concrete produced with the production method has the performance of light weight, pressure resistance and the like and can be taken as a building filling material.

Owner:TIANJIN YUJIE HONGYE CONCRETE CO LTD

Green tea processing technology

InactiveCN107114505ABright green colorThe soup is light green and translucentPre-extraction tea treatmentGreen teaTea leaf

A green tea processing technology comprises the following steps: 1) spreading: tea leaves are spread away from light in an environment with the temperature of 15-23 DEG C and the humidity of 75%-85% for 4-6 h; 2) fixation: fixation is performed at 500-600 DEG C for 1-1.5 min; 3) cooling: the leaves subjected to fixation is cooled in 30-60 s after fixation; 4) carding: carding is performed at 170-190 DEG C for 5-7 min; 5) tippy off: tippy off is performed at 120-125 DEG C for 8-12 min; 6) drying: drying comprises primary baking and after-baking, primary baking is performed at 120-130 DEG C for 7-9 min, and after-baking is performed at 120-130 DEG C for 4-5 min; 7) UHT sterilization treatment: the tea leaves are subjected to aseptic packaging after ultra-high-temperature instantaneous sterilization at the high temperature of 110-140 DEG C for 4-30 s. The tea blades of the prepared tea are light green and fresh in color, leaves are white, veins are green and edges are gold, tea residues are even and orderly in whole, tea soup is high and lasting in aroma, contains slight milky aroma or orchid aroma and is light green and transparent in color, and the tea tastes fresh and is sweet in aftertaste and is superior in quality.

Owner:叙永县罗彬茶叶种植专业合作社

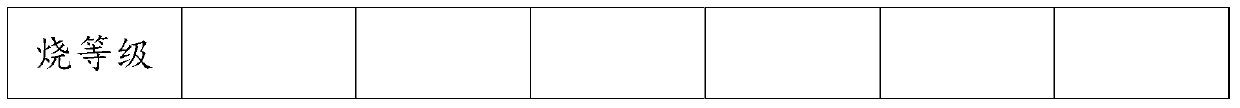

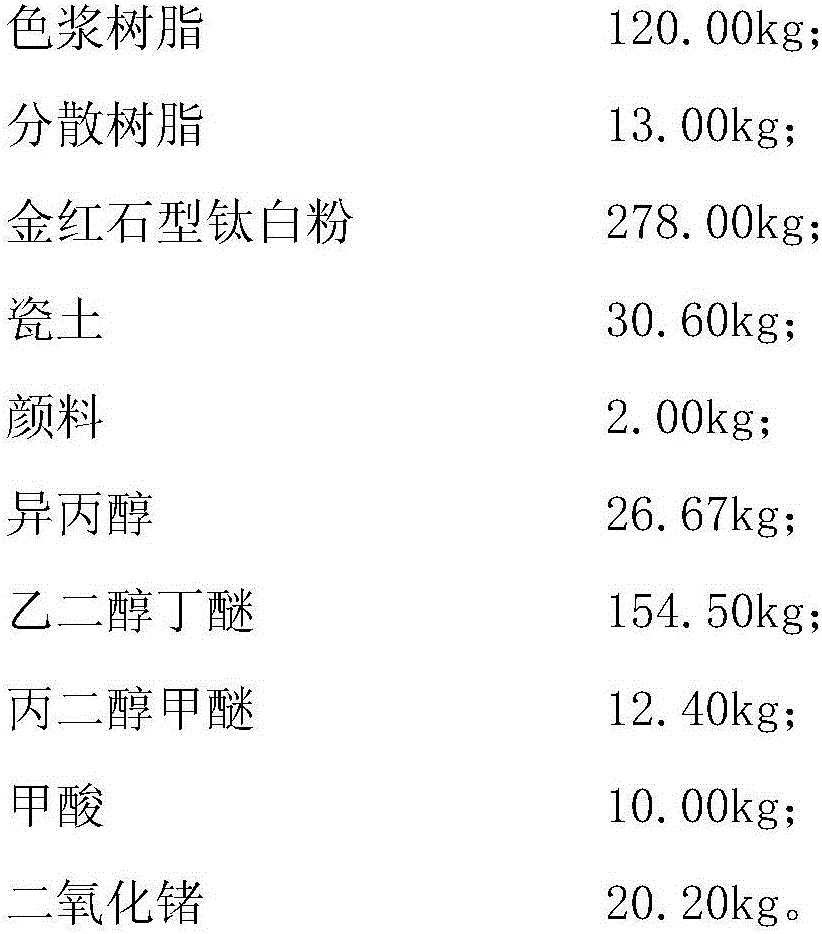

Color paste for water-based paints and production technique thereof

InactiveCN105860675ALow reaction temperatureReduce energy consumptionAnti-corrosive paintsPigment pastesWater basedDistilled water

The invention discloses a color paste for water-based paints and a production technique thereof, belonging to the technical field of anticorrosive paints. The color paste contains 2-5 wt% of oxides as an esterification reaction catalyst. The production technique comprises the following steps: adding the raw materials for producing the color paste and the 2-5 wt% of oxides into a grinding tank of a grinder, stirring uniformly, heating the materials, standing until the reaction of the raw materials finishes, grinding, and injecting into a finished product kettle; and after detecting the material in the finished product kettle, adding carboxylic acid and distilled water, blending, and stirring uniformly to obtain the color paste finished product. The production technique can lower the reaction temperature in the production process. The added oxides have the function of shortening the resin crosslinking time and leveling time, so that the paint film can be quickly dried, thereby enhancing the production efficiency and lowering the production energy consumption.

Owner:WEIFANG HELI WATER BASED PAINT MAKING CO LTD

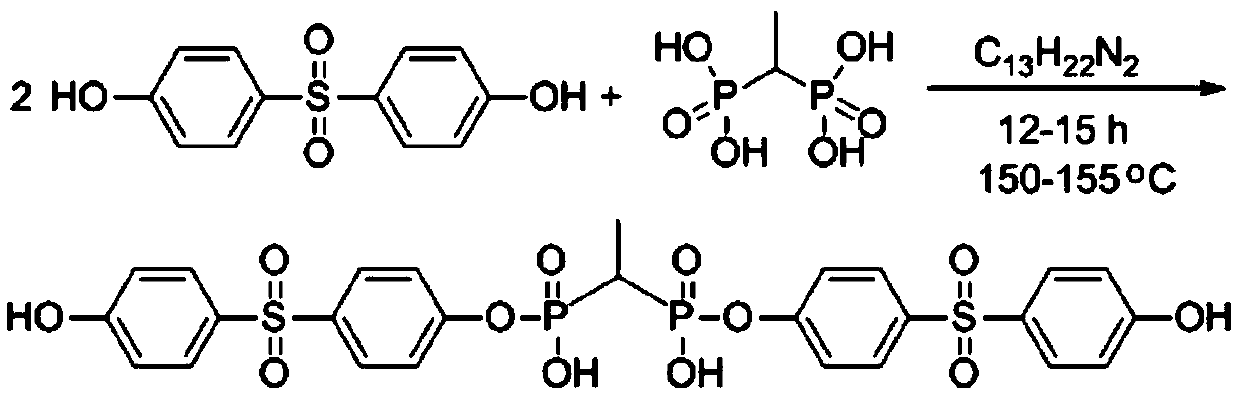

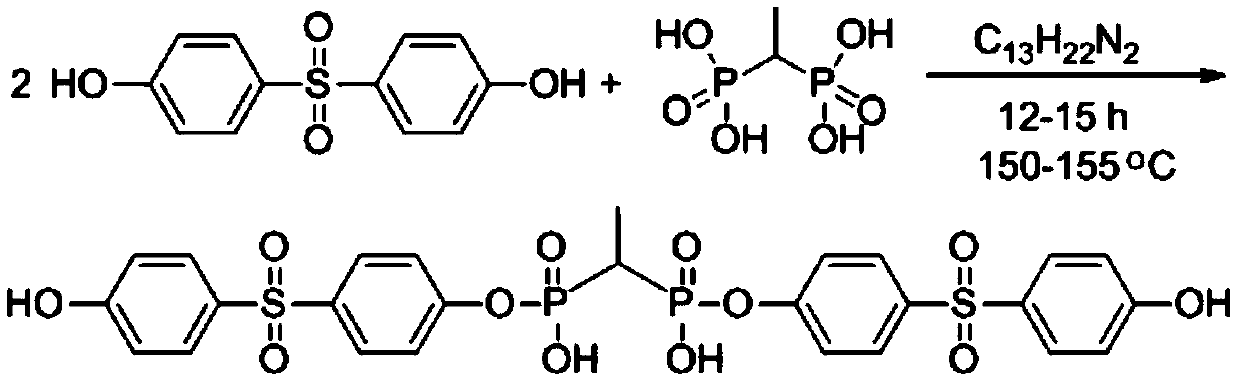

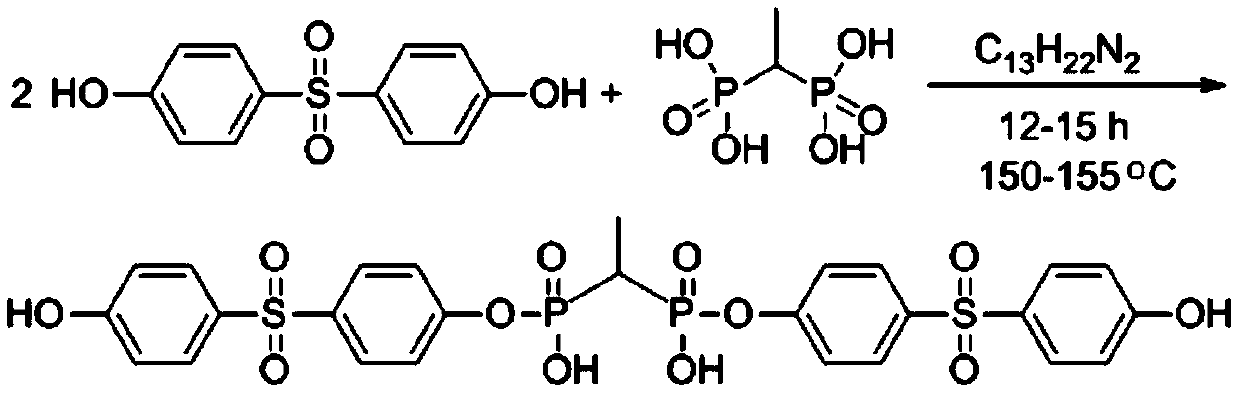

Flame-retardant phosphate-containing diol modified polyurethane coating and preparation method thereof

InactiveCN110437421AHigh char formation rateReduce flammabilityFireproof paintsPolyurea/polyurethane coatingsWater basedHigh energy

The invention relates to the technical field of flame-retardant water-based polyurethane, and discloses a flame-retardant phosphate-containing diol modified polyurethane coating and a preparation method thereof. The coating comprises the following raw materials in parts by weight: 4,4'-dihydroxydiphenylsulfone, hydroxyethylidene diphosphonic acid, an esterification catalyst, polypropylene oxide glycol, 2,4-toluene diisocyanate, 1,5-pentanediol, dihydroxybutyric acid, a synergistic catalyst, a neutralizer and a chain extender. According to the flame-retardant phosphate-containing diol modifiedpolyurethane coating and the preparation method provided by the invention, polyurethane is modified by using dihydroxydiphenylsulfonyl ethylidene diphosphonate-diol, phosphorus and nitrogen elements are introduced into a molecular chain of a water-based polyurethane polymer to form O=S=O with higher energy and better thermal stability and an aromatic benzene ring group, so that the charring rate of the polyurethane is improved, the combustibility of the polyurethane is reduced, and the water-based polyurethane coating has higher thermal stability and flame-retardant effects.

Owner:郝立勇

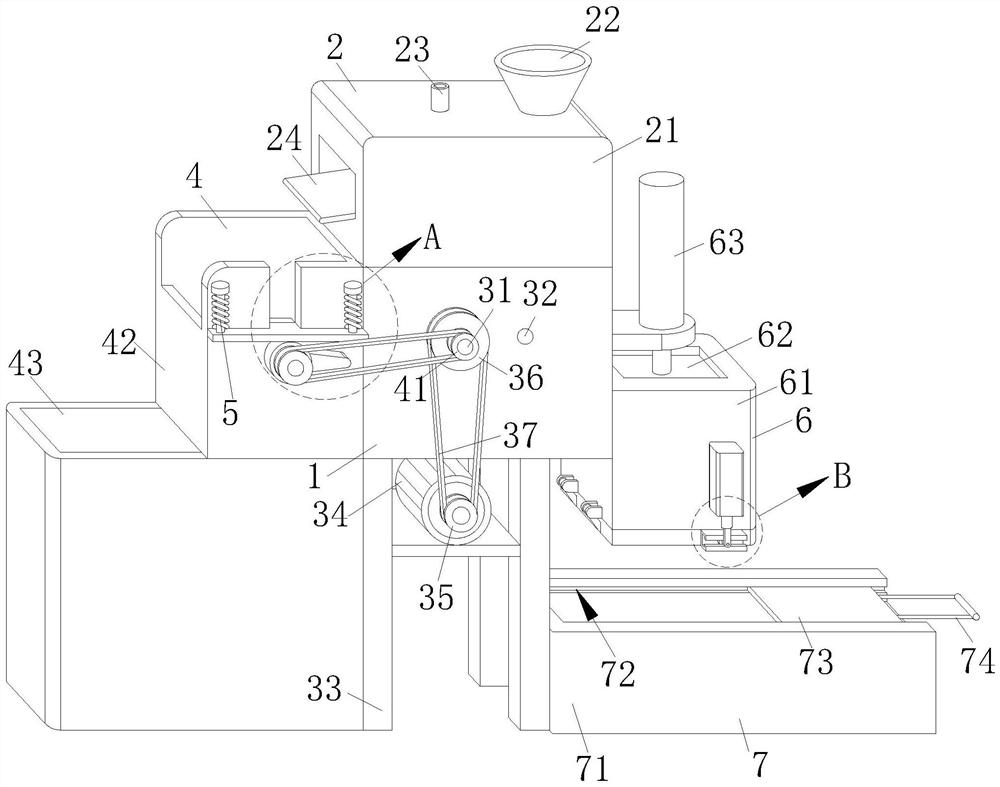

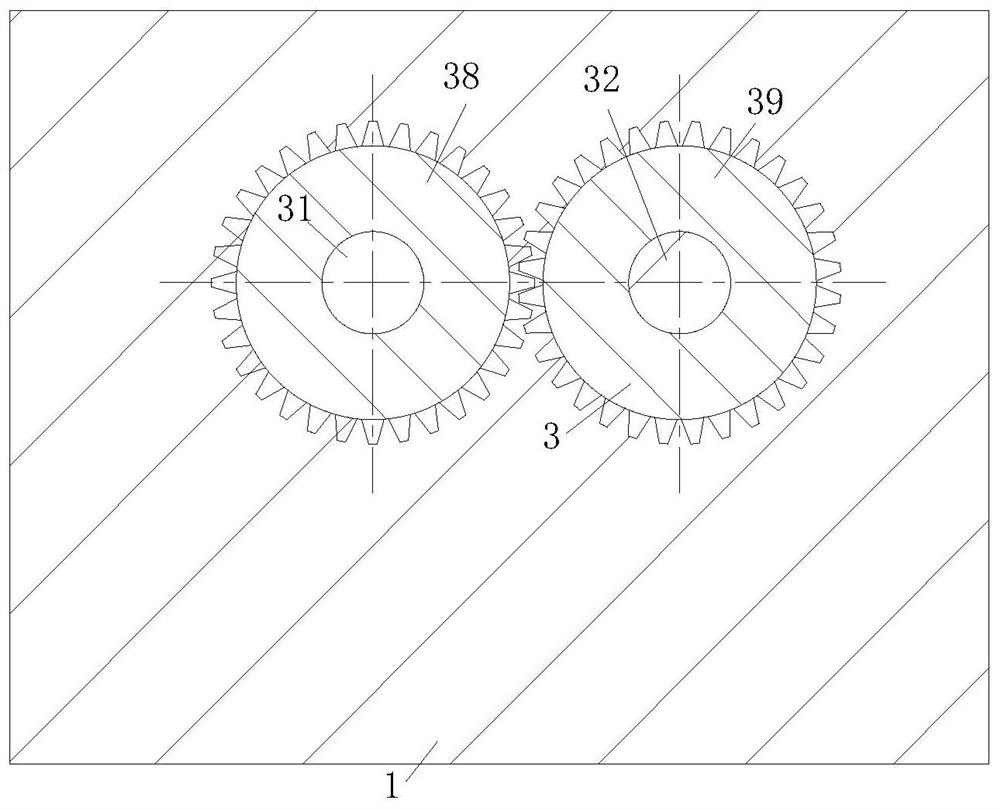

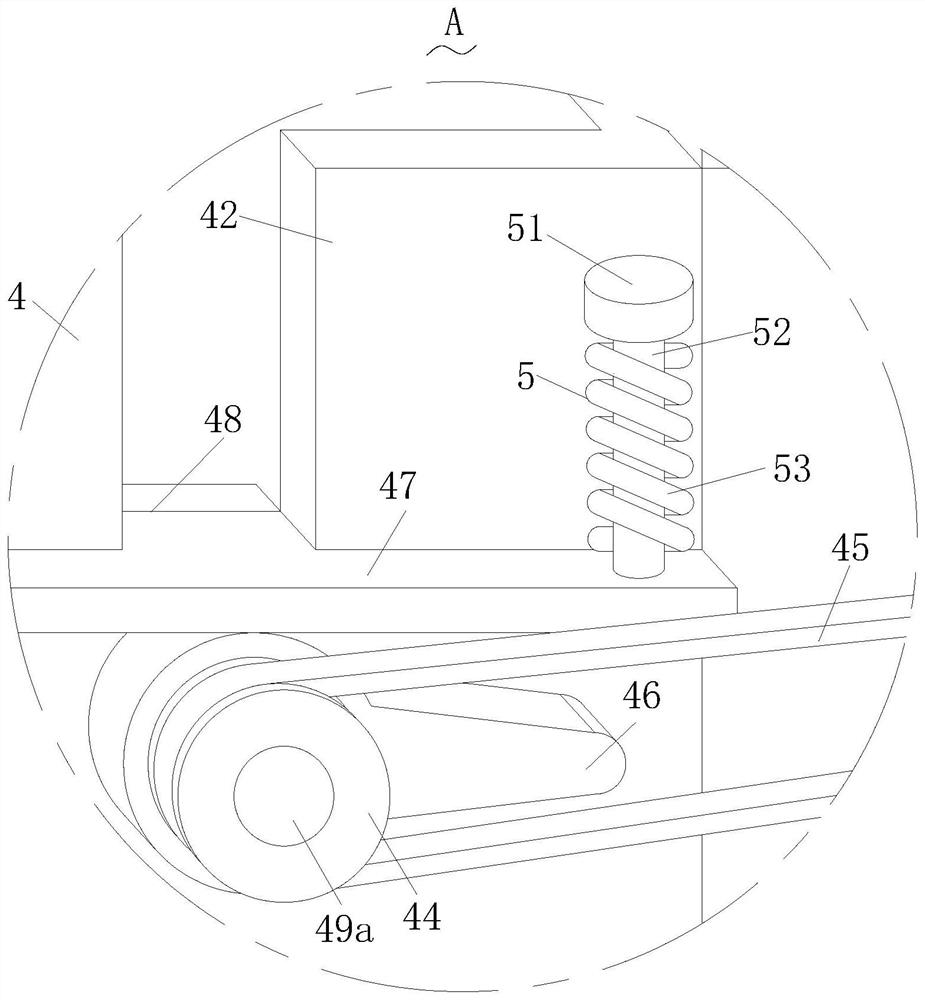

Spring cleaning equipment and spring cleaning process applying same

ActiveCN108480322APlay a role in dehydrationAvoid leavingLiquid surface applicatorsDrying solid materials without heatMegasonic cleaningEngineering

The invention provides spring cleaning equipment and a spring cleaning process applying the same. The spring cleaning equipment comprises a feeding device, a cleaning device, a discharging device anda conveying mechanism which are connected sequentially, wherein the conveying mechanism extends from the cleaning device to the discharging device. The cleaning device comprises a washing tank and dehydration tank which are arranged successively, and dehydration solvents are injected into the dehydration tank. The washing tank comprises a plurality of ultrasonic cleaning tanks which are connectedsequentially. The spring cleaning process comprises the following steps of A, vibration ash removal; B, flattening; C, ultrasonic cleaning for the first time; D, air suction for the first time; E, ultrasonic cleaning for the second time; F, air suction for the second time; G, ultrasonic cleaning for the third time; H, air suction for the third time; I, dehydration; J, rust-proof treatment and K, discharging. According to the spring cleaning equipment and the spring cleaning process applying the same, residual water after spring cleaning can be better removed, the storage time and the service life of springs are prolonged.

Owner:浙江兰菱机械股份有限公司

Supply mechanism of container inner wall cleaning device for machining

ActiveCN113369260AReduce processingPlay a role in dehydrationHollow article cleaningDrying gas arrangementsThermodynamicsWater resources

The invention discloses a supply mechanism of a container inner wall cleaning device for machining, and belongs to the technical field of machining. The supply mechanism comprises a first storage barrel and a second storage barrel which are used for providing liquid for a first concentration box, and further comprises an air heater used for conveying materials for a second concentration box and a recycling box used for recycling waste liquid. The first storage barrel and the second storage barrel are both installed in a storage box, a first water pump and a second water pump are further installed in the storage box, the input end of the first water pump separately communicates with the first storage barrel and the second storage barrel through electromagnetic valves, the output end of the first water pump communicates with the first concentration box through a liquid conveying pipe provided with an electromagnetic valve, and the first concentration box communicates with wiping cloth. The output end of the second water pump communicates with the recycling box through a recycling pipe, the input end of the second water pump communicates with the second concentration box through an electromagnetic valve, and the output end of the air heater communicates with the second concentration box through an air conveying pipe. According to the supply mechanism of the container inner wall cleaning device for machining, and the technical purposes of saving water resources and improving the flushing and drying work efficiency can be achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

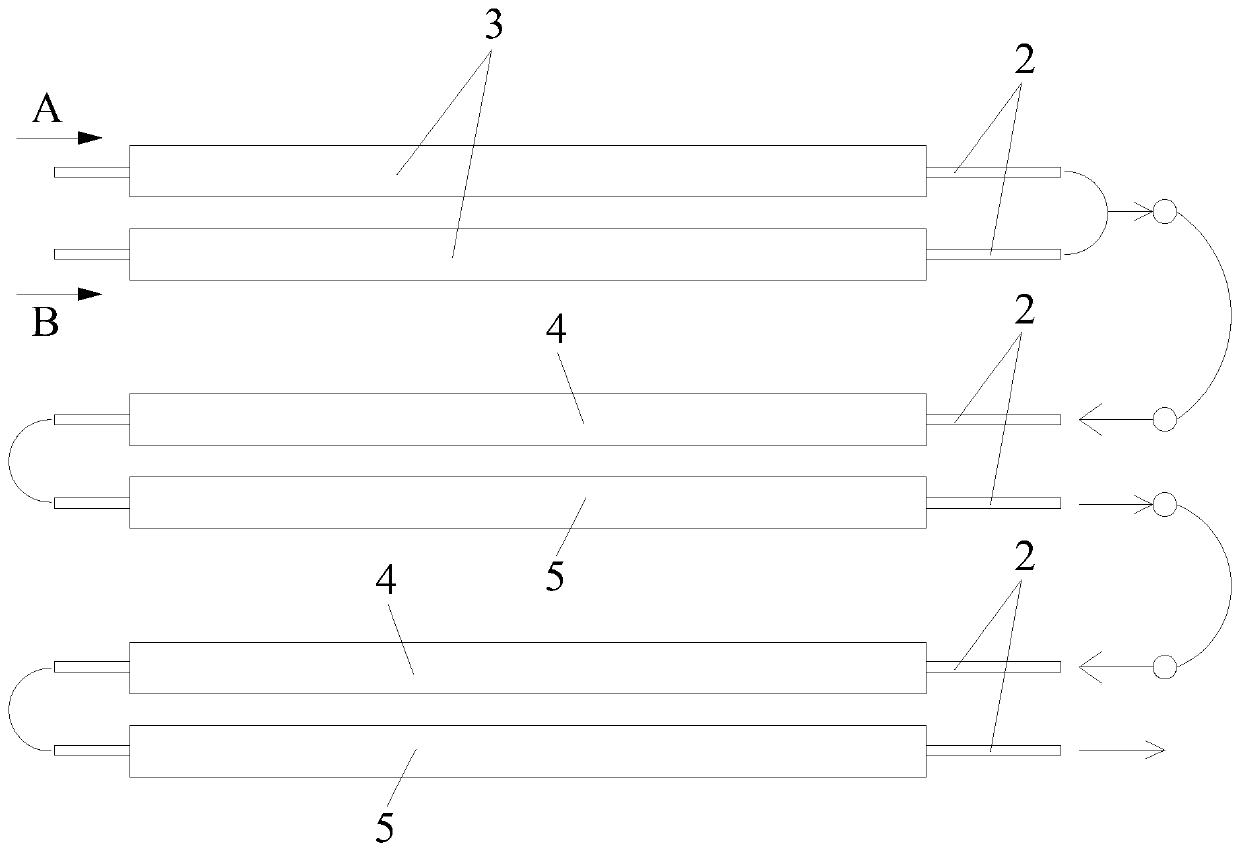

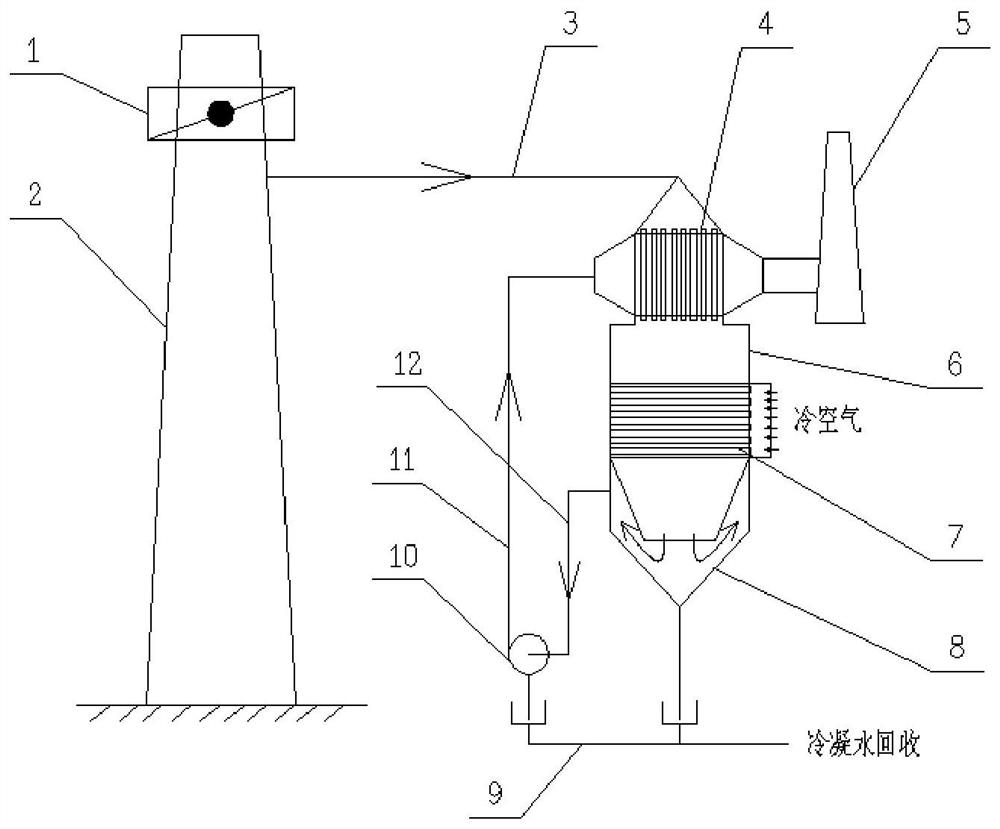

An intensive smoke plume treatment and purification system and method

ActiveCN110772938BAchieve recyclingReduce the temperatureGas treatmentDispersed particle separationCold airFlue gas

The invention discloses an intensive smoke plume treatment and purification system and method, comprising a first heat exchanger and a second heat exchanger, the first heat exchanger communicates with the second heat exchanger; the first heat exchanger includes a pipe body And the shell wrapped outside the tube, the tube is used for flue gas circulation, the shell is used for exhaust gas circulation, the temperature of the tube is higher than the temperature of the shell; the second heat exchanger includes the tube and the shell wrapped outside the tube body, the tube body is used for cold air circulation, the shell is used for flue gas circulation, and the temperature of the shell is higher than the temperature of the tube body; the shell outlet of the first heat exchanger is used for the discharge of flue gas. The present invention can realize the comprehensive control of smoke plume through reasonable equipment design and ingenious system design, especially for renovation projects, it can effectively solve the problems of difficulty in implementing smoke plume control and poor control effect by taking advantage of extremely small land occupation.

Owner:BERIS ENG & RES CORP

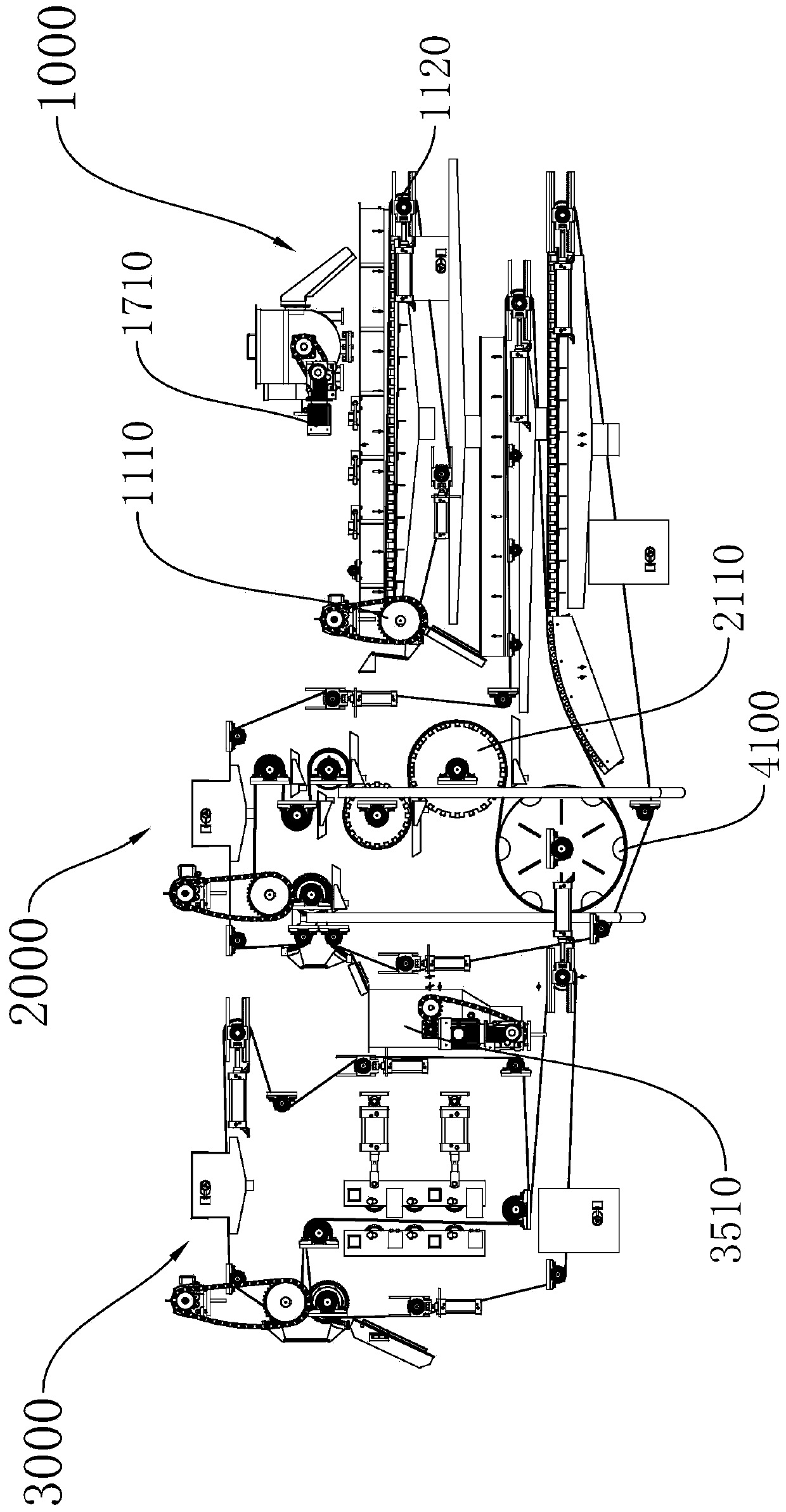

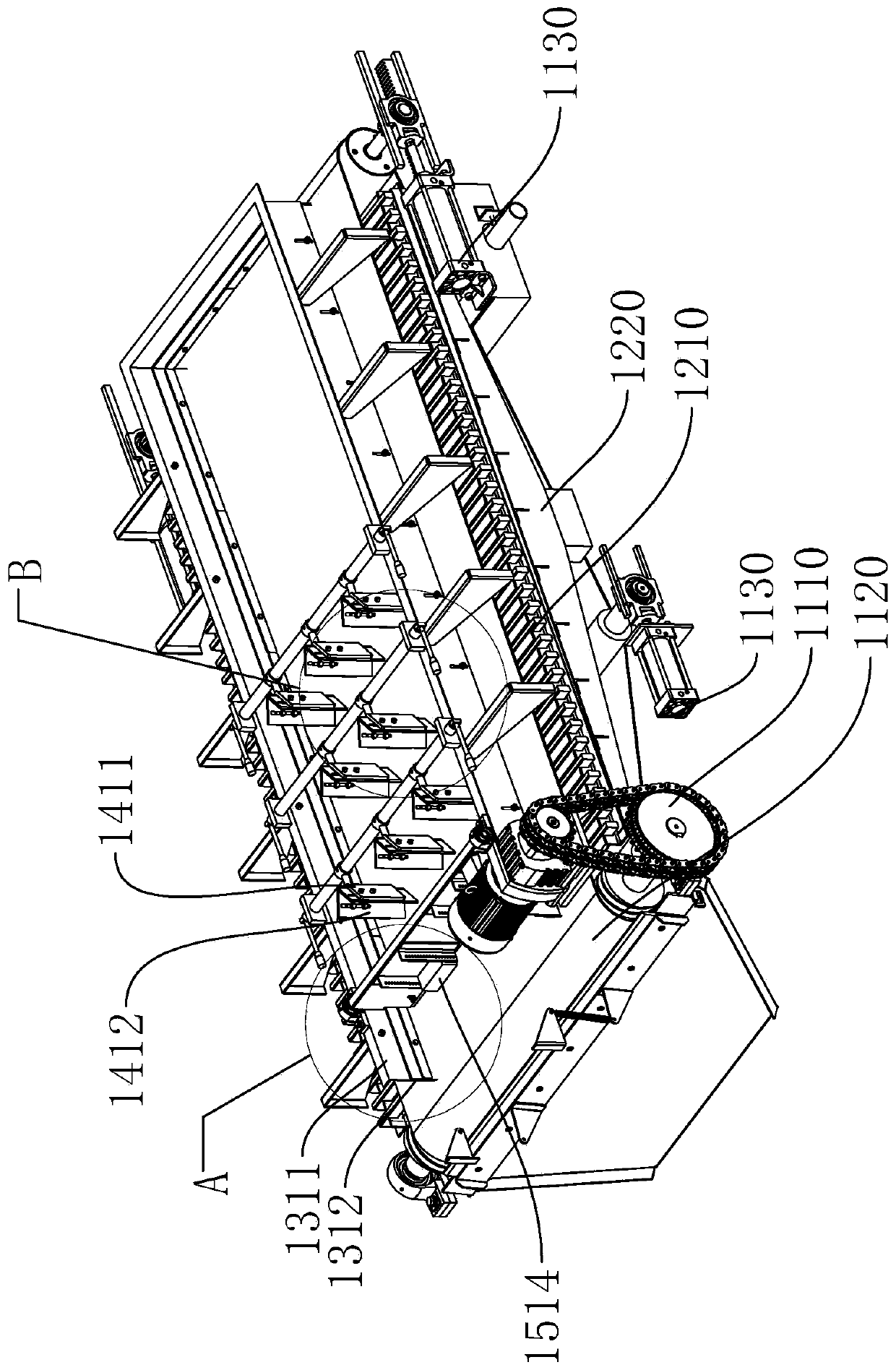

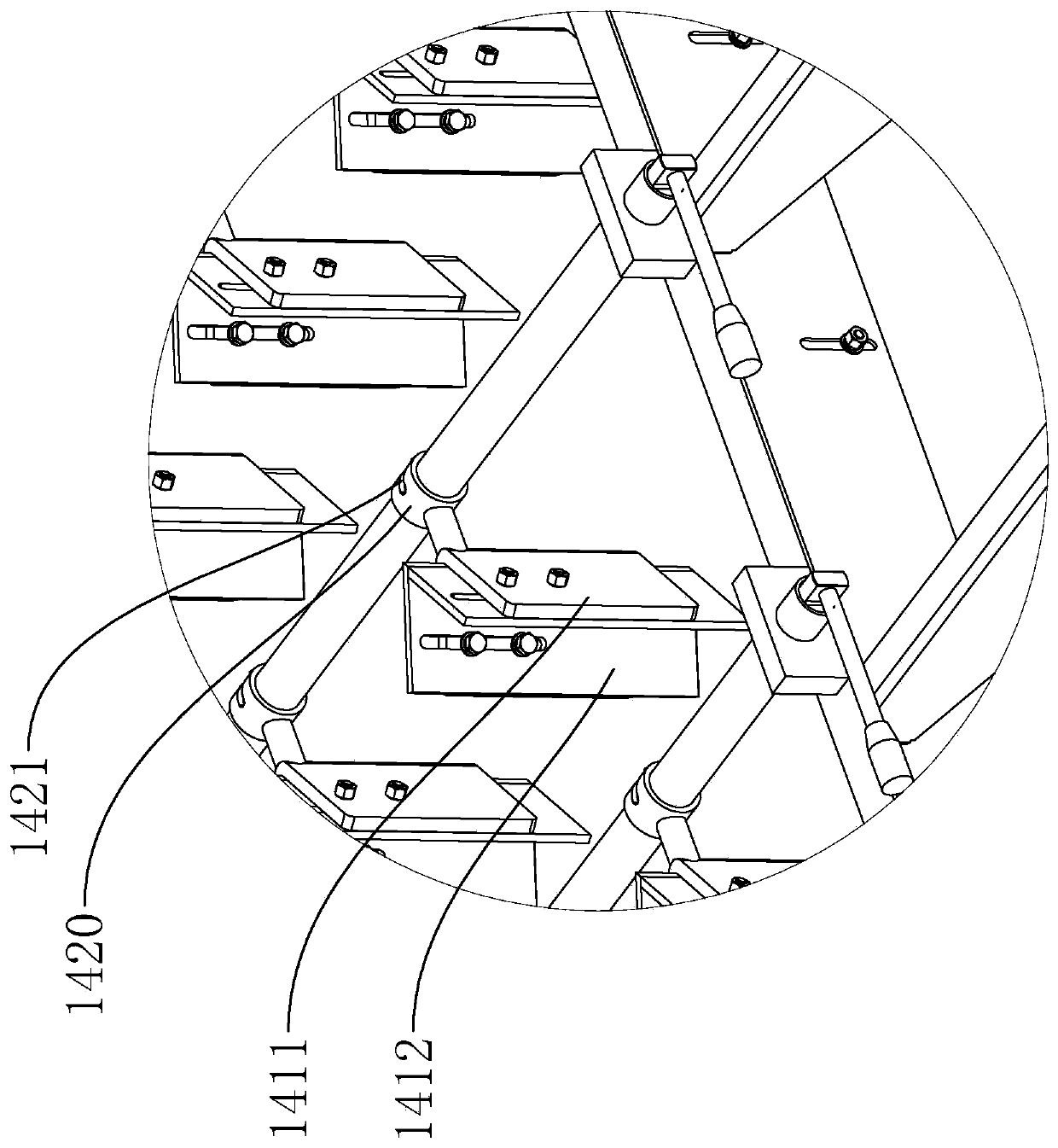

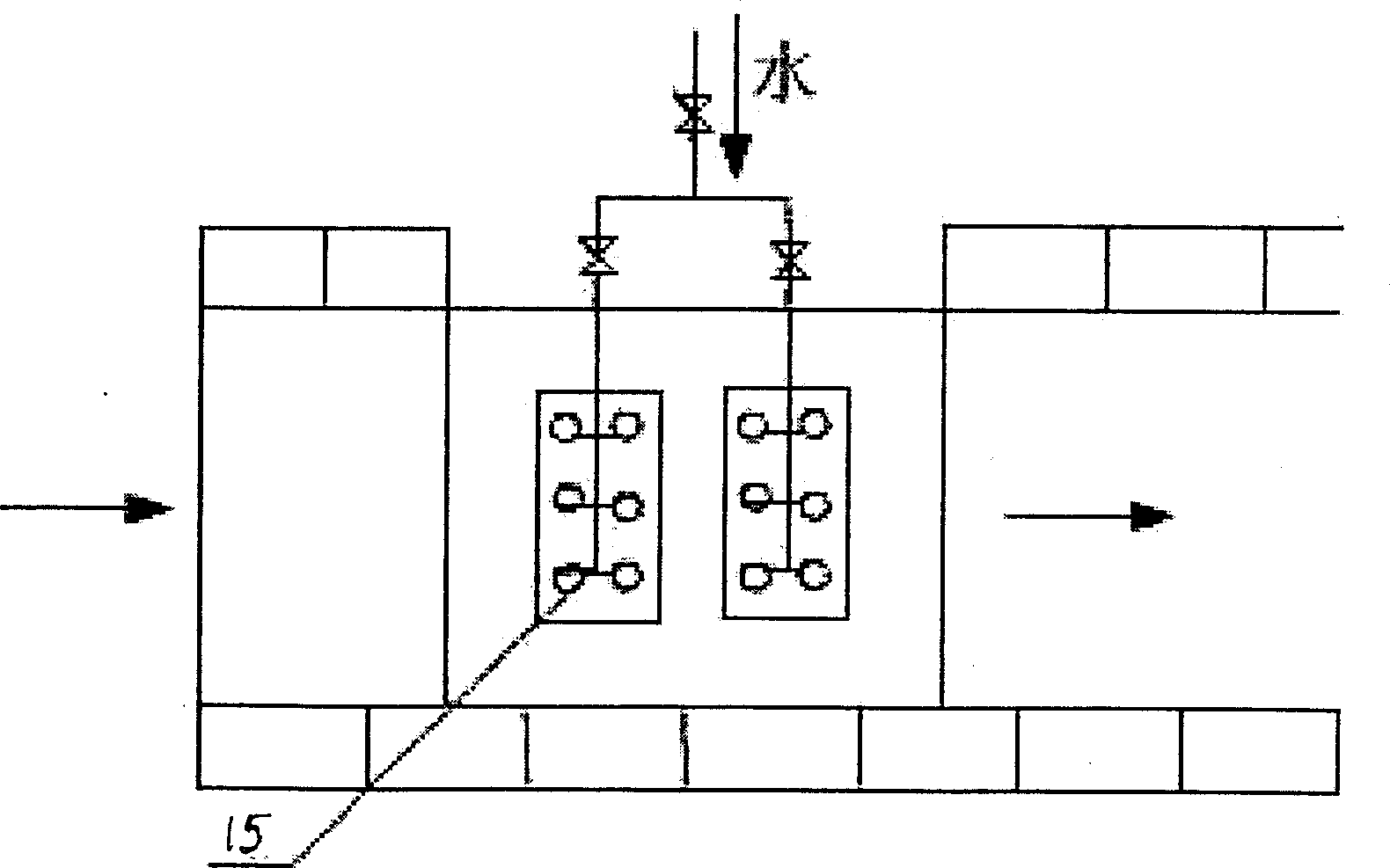

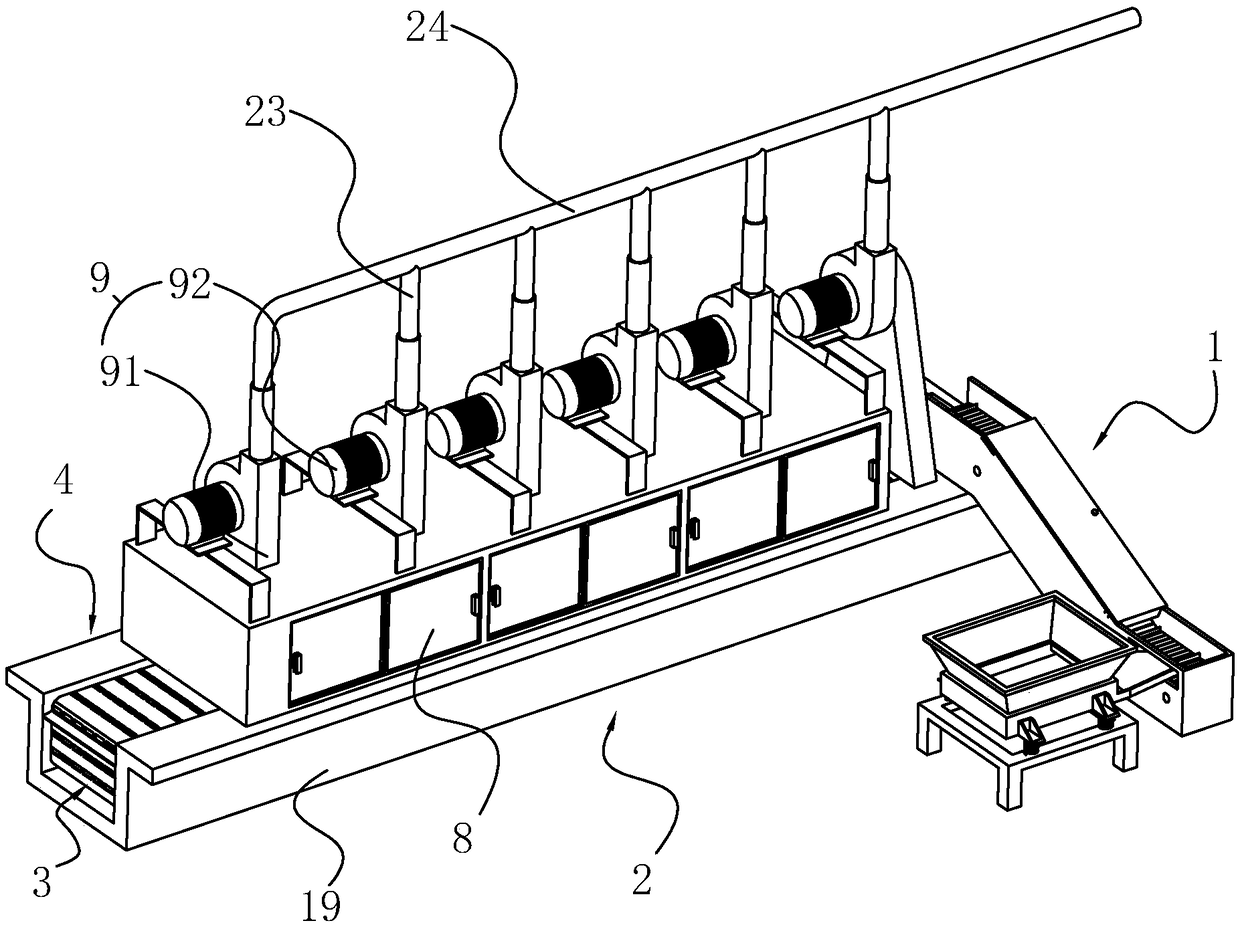

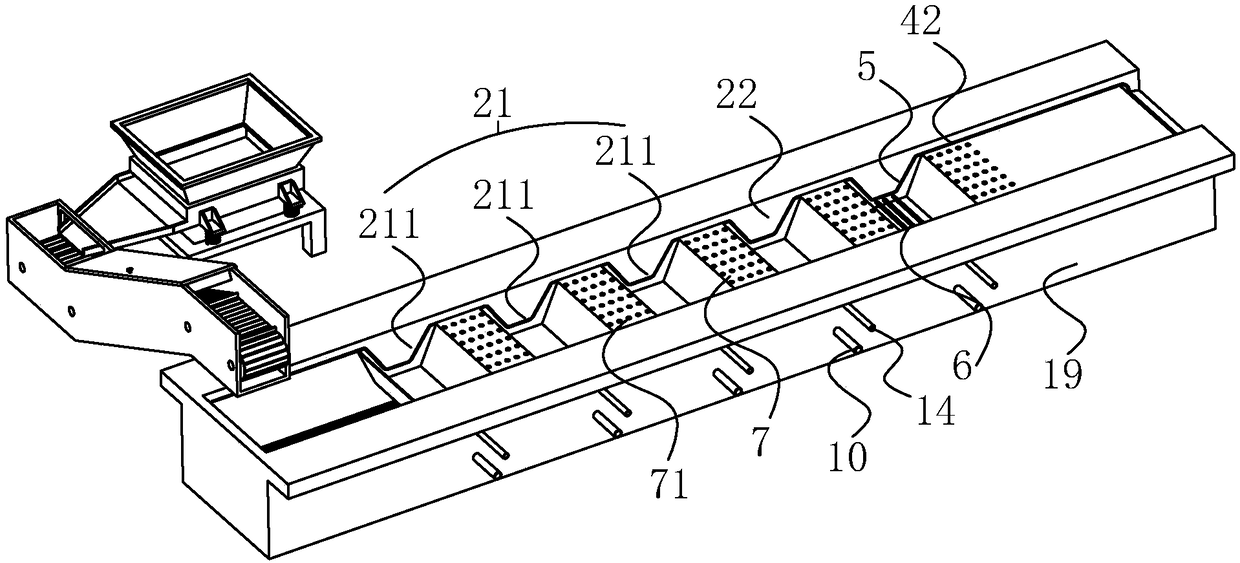

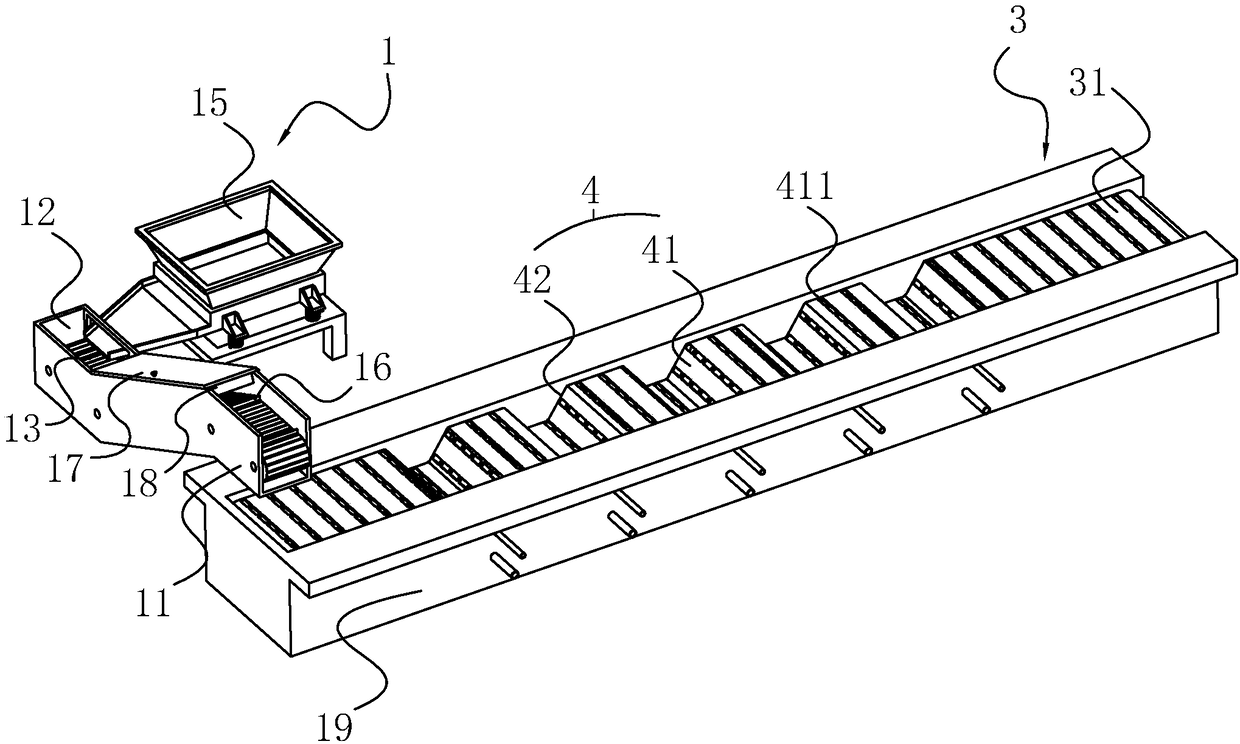

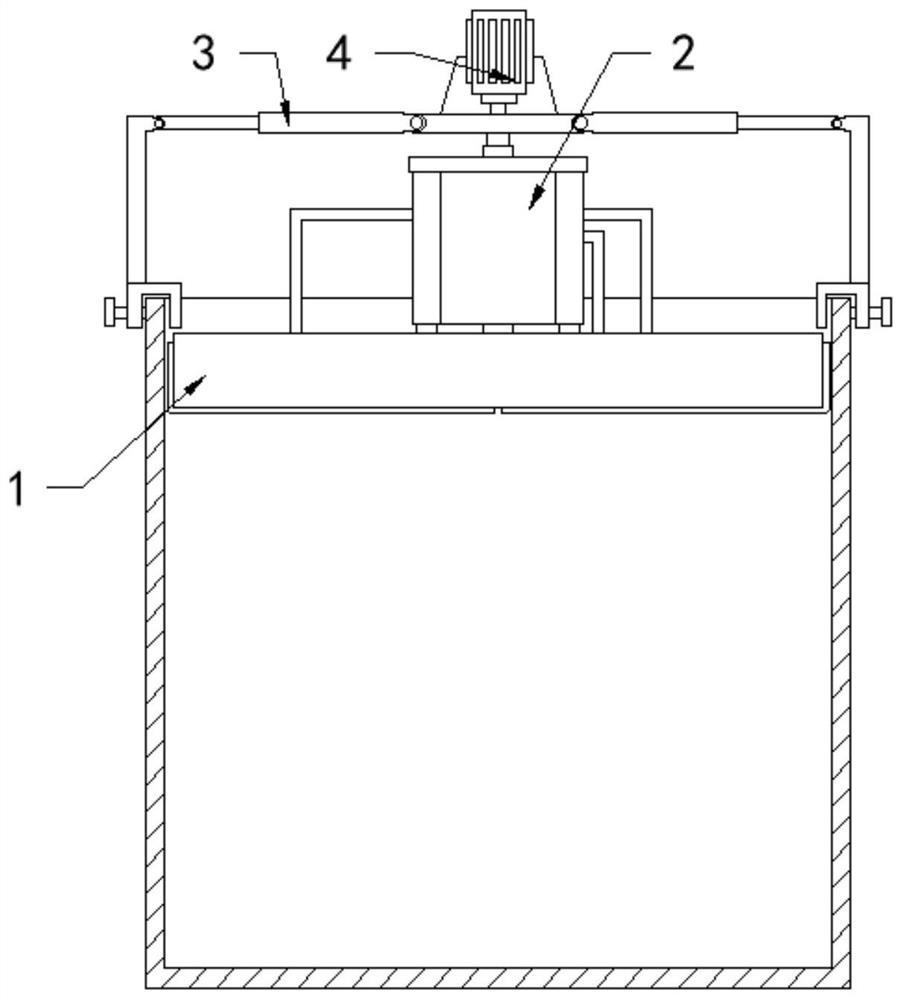

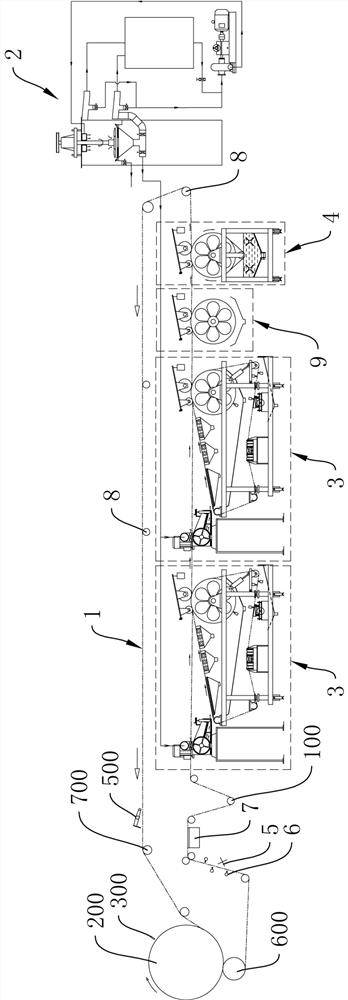

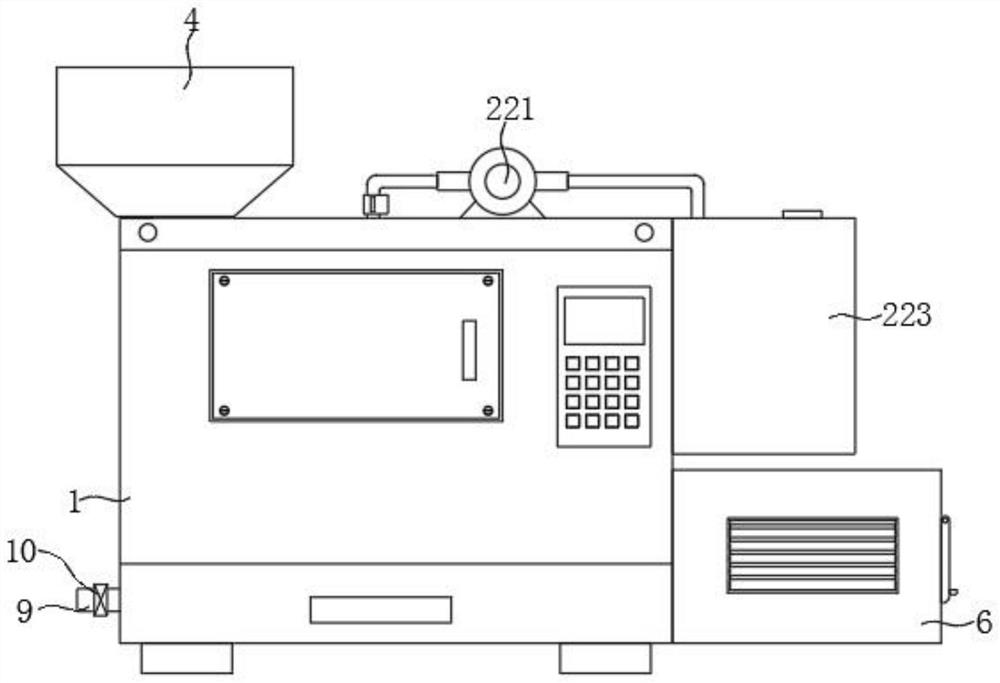

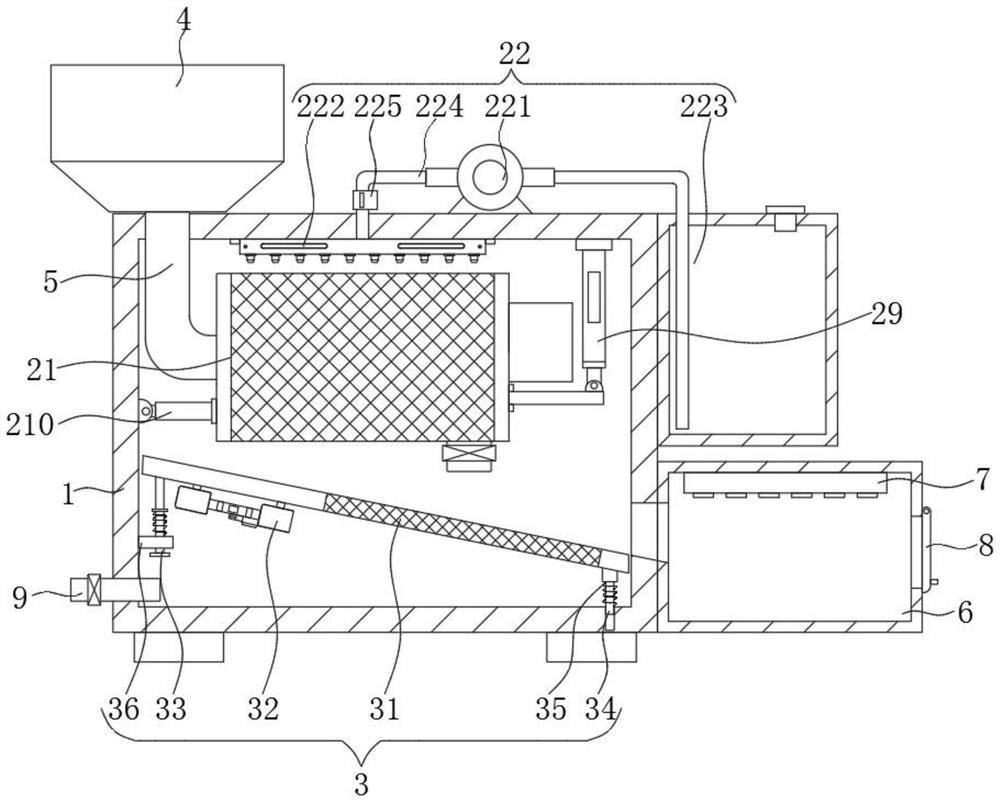

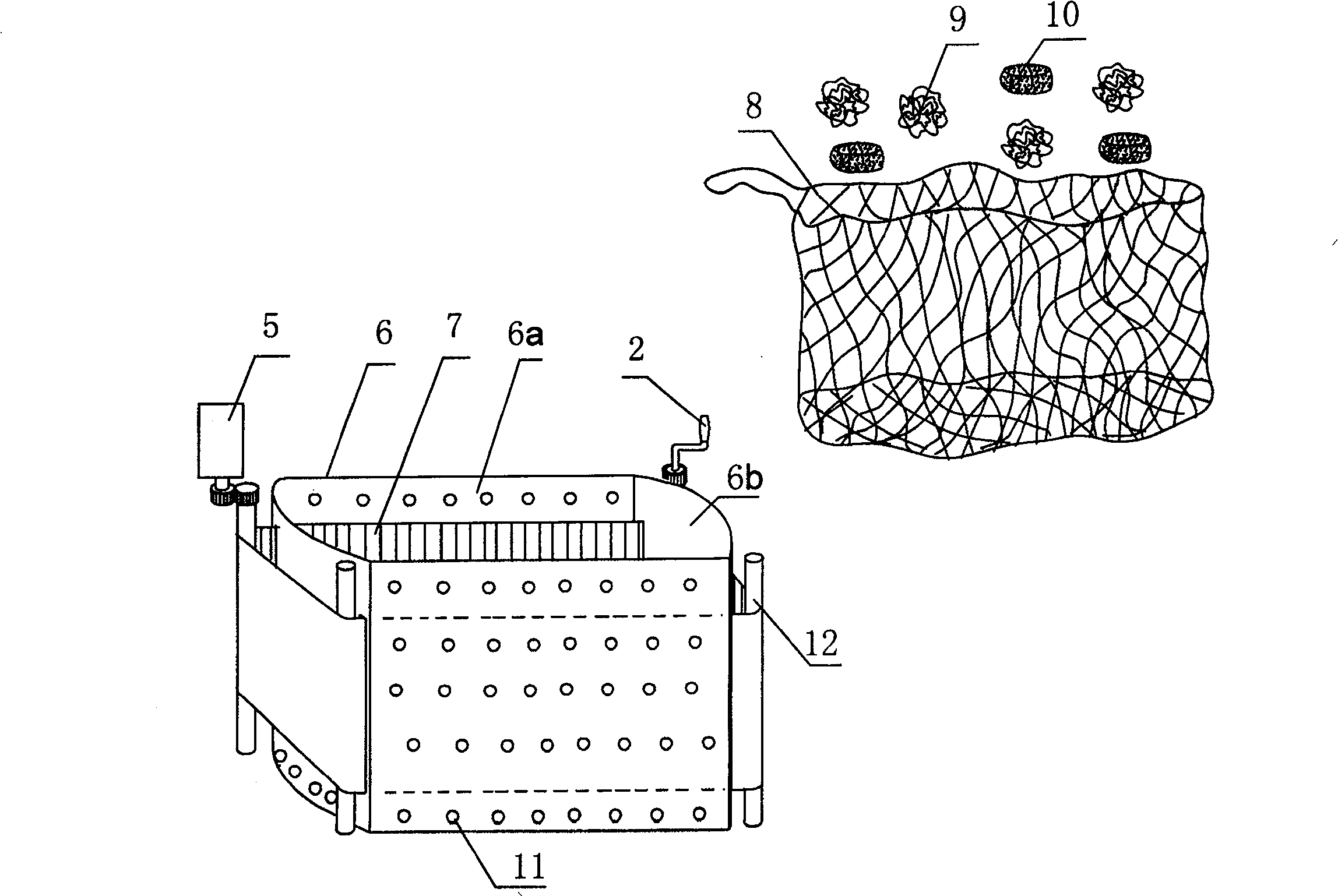

A jet lay-up board system

ActiveCN110004759BImprove reliabilityGuaranteed reliabilityInorganic fibres/flakesPaper-making machinesMolding machineElectric machine

The invention relates to a jet layup board-producing system. The jet layup board-producing system comprises a woolen blanket, a slurry stabilizing filter tank, a plurality of jet-type slurry spreadingmoulding machines, a colorant adding machine, a cloth puncher, a woolen blanket flushing assembly, a vacuum water suction box and a plurality of supporting rolls, wherein the slurry stabilizing filter tank is arranged beside the woolen blanket; each jet-type slurry spreading moulding machine comprises a jetting device and a moulding device; each jetting device comprises a support, a driving motor, a feed pipe, a balancing valve, a stirring propeller, a slurry jetting head, a dispersing component and a flow control assembly; each moulding device comprises a machine frame, a first dewatering assembly, at least one second dewatering assembly, a first cylindrical net cage, a first couch roll, a moulding cloth belt, an upper water receiving tank body, a lower water receiving tank body, a flushing assembly and a plurality of guide rolls; the colorant adding machine comprises a colorant tank, a second cylindrical net cage, a swinging rod, a colorizing roll, colorizing net cloth and a secondcouch roll; and the cloth puncher, the woolen blanket flushing assembly and the vacuum water suction box are arranged beside the woolen blanket. The jet layup board-producing system has the advantagesof a good shaping effect, low production cost, high reliability, high processing quality and the like.

Owner:FOSHAN JINFU PANEL

Pickling equipment for ginger processing

The invention provides pickling equipment for ginger processing. The pickling equipment for ginger processing comprises: a machine body; and a cleaning structure, wherein the cleaning structure is arranged in the machine body, and the cleaning structure comprises a cleaning cylinder and a water spraying assembly. According to the pickling equipment for fresh ginger processing, the cleaning structure is arranged, the pickling equipment has the cleaning and automatic discharging functions at the same time; during cleaning, high-pressure water is sprayed out through a water spraying head, fresh ginger is continuously stirred in cooperation with a stirring piece, and then the fresh ginger is effectively cleaned, so that the cleaning effect is more uniform, comprehensive and rapid, the fresh ginger can be better dried in the later period; by arranging an electric telescopic rod and a supporting column to be used in cooperation, automatic discharging operation of the fresh ginger can be achieved, discharging becomes more convenient and more labor-saving, excessive manual operation is not needed, the whole device is very easy in the cleaning process, and the use requirements of people can be well met.

Owner:安徽谷瑞农业科技开发有限公司

Mud dewatering and separating equipment with smashing function

InactiveCN112744998AKeep alivePlay the role of shakingSludge treatmentEnvironmental engineeringFishing

The invention relates to the field of mud dewatering and separating equipment, in particular to mud dewatering and separating equipment with a smashing function, which comprises a smashing box, a separating structure, a smashing structure, a fishing structure, a guiding structure, a dewatering structure and a collecting structure, the separating structure is installed at the top end of the smashing box, fishes and other organisms in mud of a pond or a river shoal can be separated and lifted out, the separated fishes and other organisms can be cleaned, and therefore the activity of the fishes and other organisms is guaranteed, and the effect of protecting the ecology is achieved; the smashing structure is arranged on one end of the smashing box, sand and stones in mud can be thoroughly crushed, so that later mud dewatering work and cake pressing reutilization are facilitated, the smashing structure can synchronously drive the fishing structure to work while performing smashing work, and separated fishes can be fished out from clear water through work of the fishing structure; therefore, later-stage releasing is facilitated, and the fishes can better survive.

Owner:郭玉明

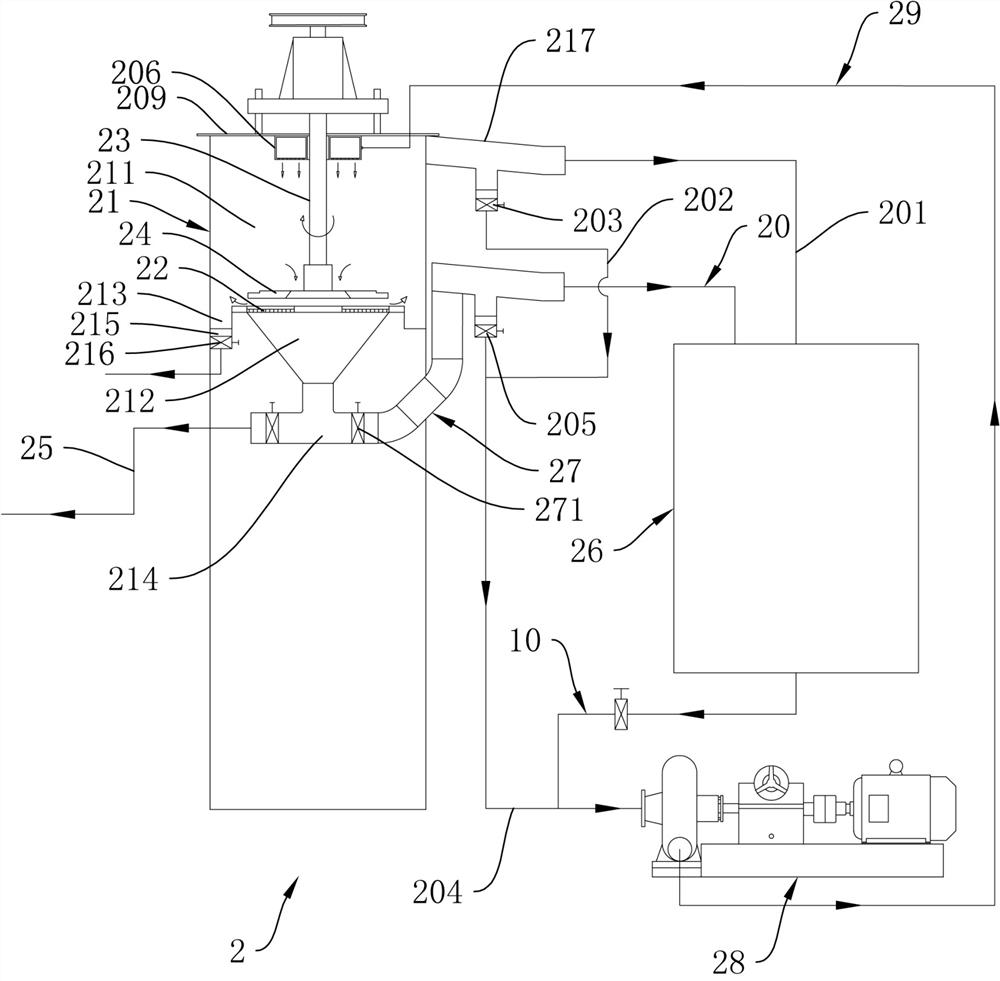

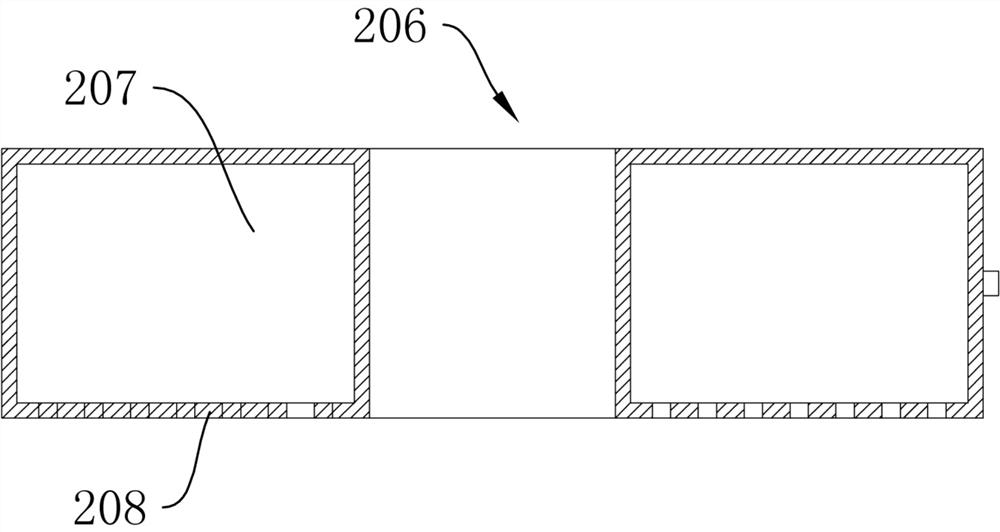

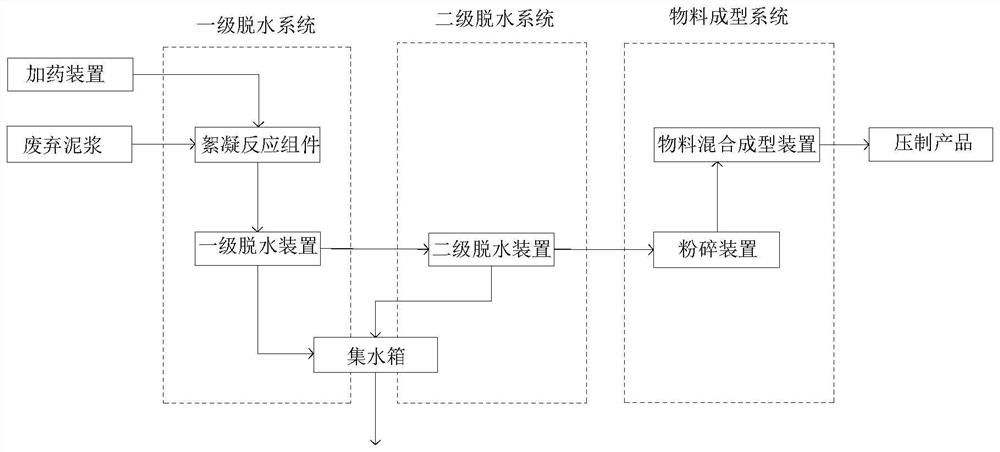

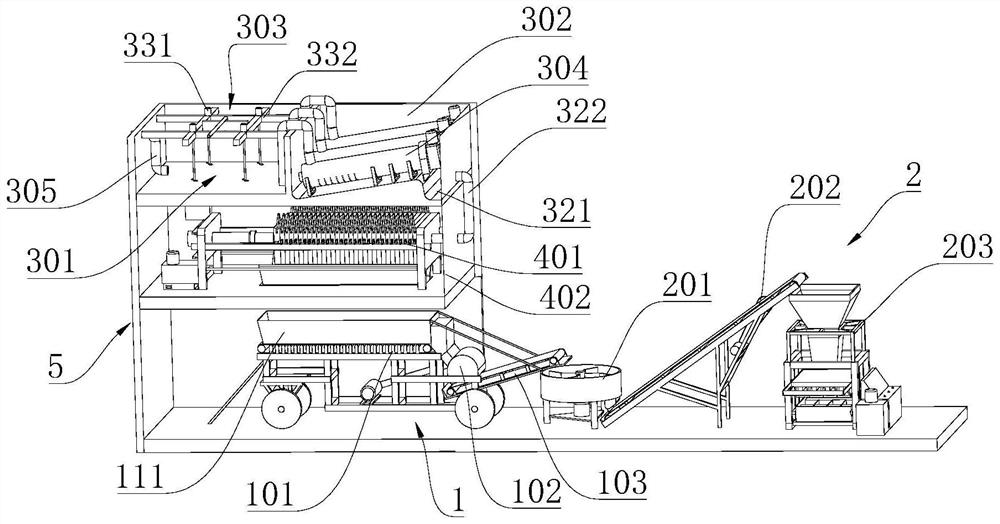

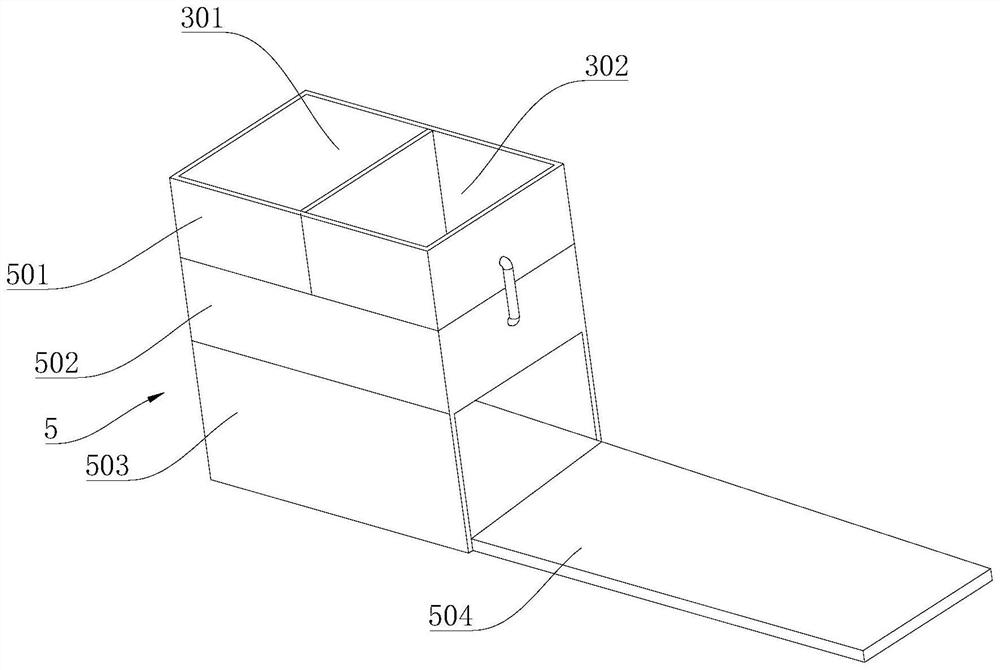

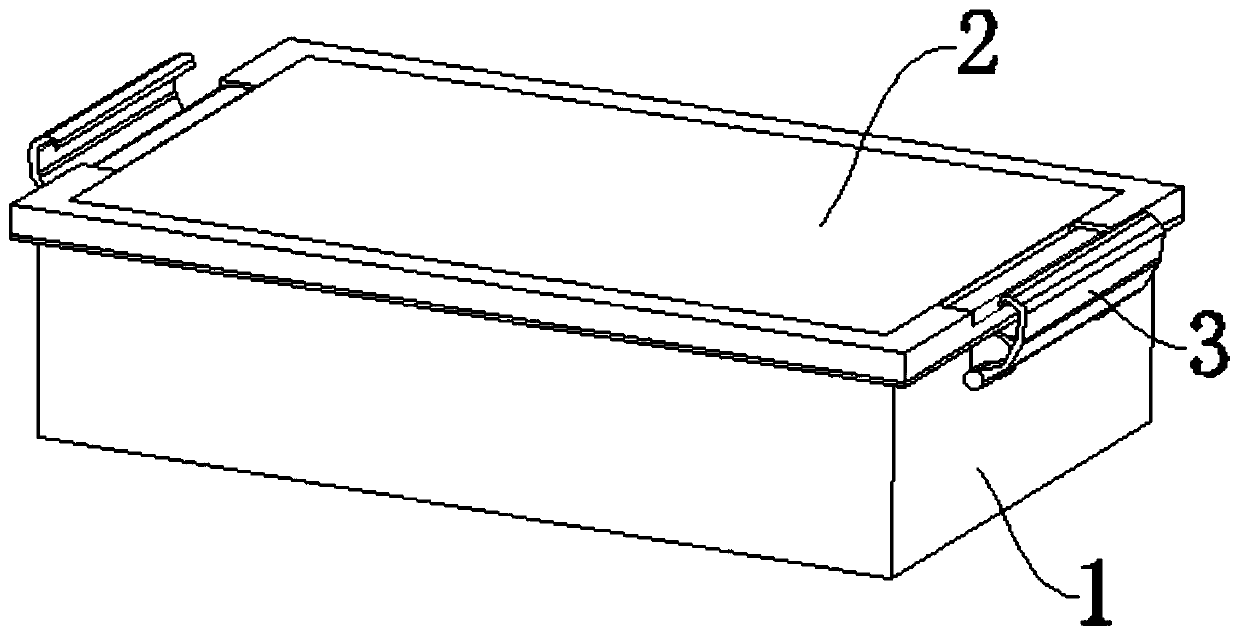

Slurry shield construction waste slurry productization forming system

PendingCN114804580AUniform textureRaise the level of disposalSludge treatment by de-watering/drying/thickeningTransportation and packagingProcess engineeringMining engineering

The invention discloses a productization forming system for slurry shield construction waste slurry, and relates to the technical field of waste slurry treatment. A slurry shield construction waste slurry productization forming system comprises a supporting frame, a first-stage dehydration system, a second-stage dehydration system and a material forming system, wherein the first-stage dehydration system, the second-stage dehydration system and the material forming system are communicated in sequence. The primary dehydration system is arranged on the support frame and is used for dehydrating the waste slurry to obtain concentrated slurry; the secondary dehydration system is arranged on the support frame and is used for compressing and dehydrating the concentrated slurry to obtain a mud cake; the material forming system is arranged on the supporting frame and used for smashing the mud cakes into mud powder, mixing the mud powder with additional materials and pressing the mixture into blocks. According to the invention, the brick is formed through multi-stage dehydration and compression molding, and the baking-free brick product with uniform texture and up-to-standard strength can be directly obtained through the process.

Owner:SOUTHWEST JIAOTONG UNIV

Moisturizer and application thereof to calligraphy moisturizing box

PendingCN110696525AAvoid lossIncrease relative volatilityBiocideBiochemical fibre treatmentBiotechnologyMicroorganism

The invention discloses a moisturizer and application thereof to a calligraphy moisturizing box. The moisturizer comprises ethyl alcohol, acetic acid and water, wherein the mass percentage of the ethyl alcohol, the acetic acid and water is 25%:2.5%:72.5%. The calligraphy moisturizing box comprises a box body, a box cover, buckle plates, an ink dish storage area, a bottled moisturizer and a writingbrush rack; the box cover is arranged on the box body; the buckle plates are arranged on two sides of the box body; the ink disk storage area is molded at the bottom of the inner side of the box body; and the bottled moisturizer is arranged on one side of the ink disk storage area. The ethyl alcohol does not perform a chemical reaction with the acetic acid in the moisturizer under constant temperature and constant pressure, the ethyl alcohol and the acetic acid can be stored stably for a long time, the ethyl alcohol has a dehydration effect on microorganisms such as bacteria, the acetic acidplays a role in damaging acid-base balance on microorganisms such as bacteria, after the ethyl alcohol and the acetic acid are combined, the anticorrosion effect is outstanding, and the moisturizer isweighed and prepared only according to a common solution preparation method.

Owner:周礼君

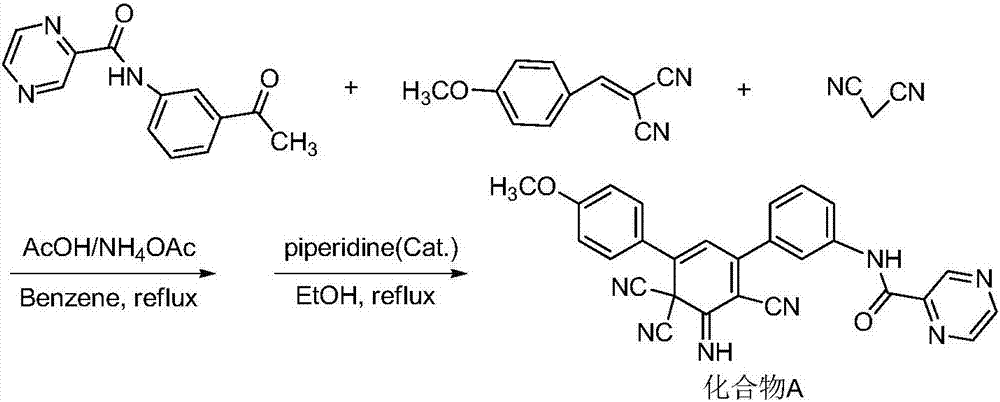

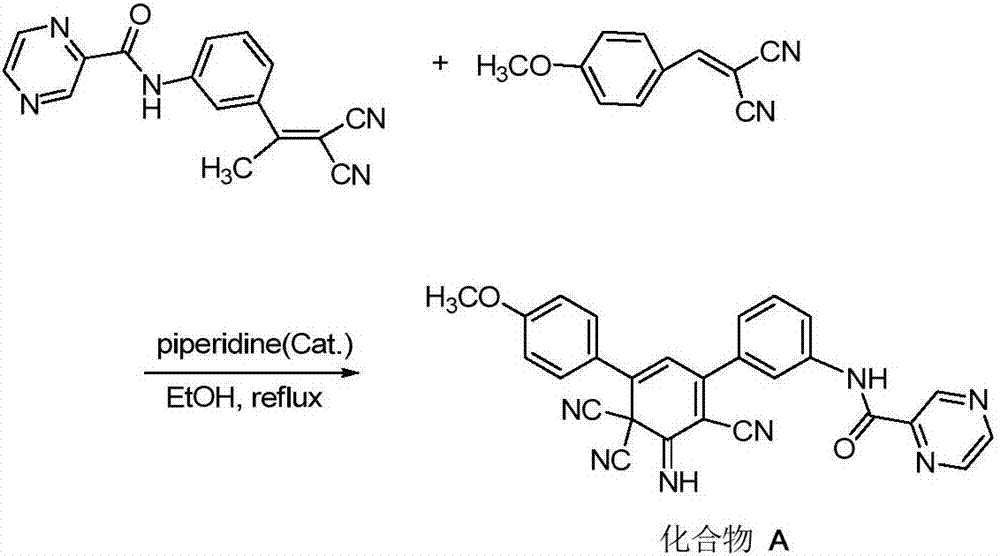

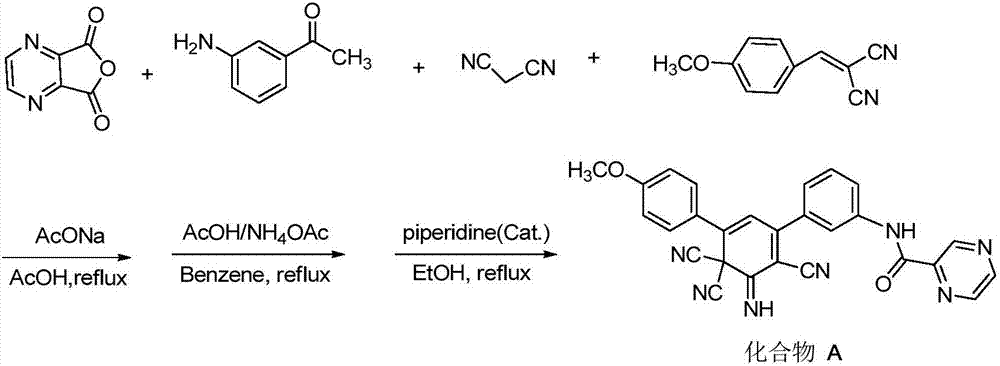

A kind of synthetic method of 3,5-diaryl-2,6,6-tricyano-1-imino-2,4-cyclohexadiene derivative

InactiveCN106083649BLow priceReduce usageCarboxylic acid nitrile preparationOrganic compound preparationNatural productDehydrogenation

The invention discloses synthesis method of a 3,5-diaryl-2,6,6-tricyan-1-imino-2,4-cyclohexadiene derivative. The method is as below: reacting a chalcone derivative with a malononitrile dimer under the promotion of alkali at room temperature to obtain a corresponding Michael adduct; then subjecting the Michael addition product to cyclization and dehydrogenation oxidation under the promotion of alkali to obtain the 3,5-diaryl-2,6,6-tricyan-1-imino-2,4-cyclohexadiene derivative. Compared with the traditional method, the two-step synthesis of the invention uses ordinary alkali with low price as a catalyst, so as to effectively reducing the cost and reach high product yield. Especially, in the construction of cyclohexadiene derivative, the method can realize greater flexibility in the selection of a substituent in cyclohexadiene. The 3,5-diaryl-2,6, 6-tricyan-1-imino-2,4-cyclohexadiene derivative synthesized by the method can be used in the fields of synthesis of heteropolycyclic chemical and natural antibiotics, synthesis of anticancer drug, and research on structural modification of natural products.

Owner:SHAANXI NORMAL UNIV

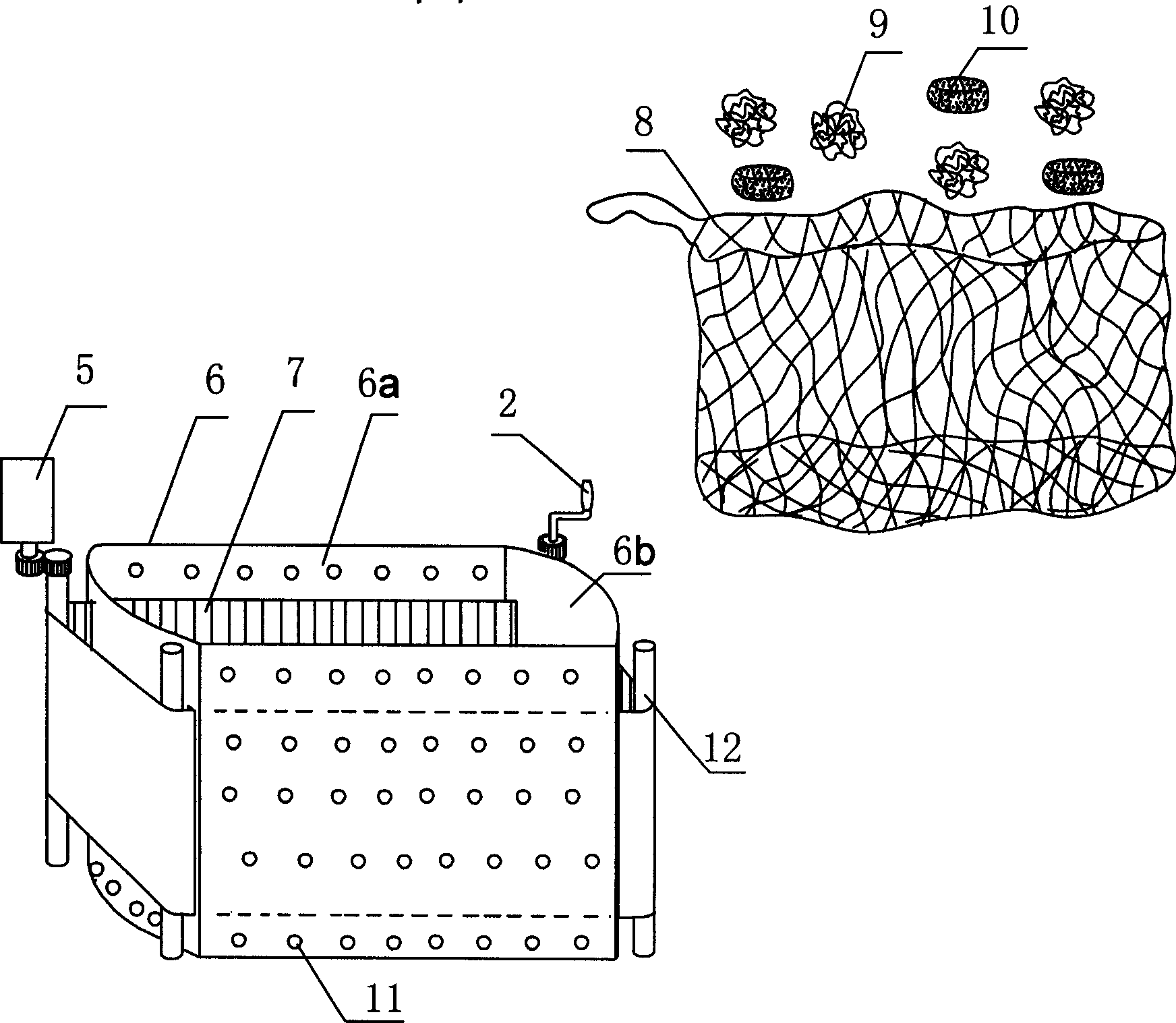

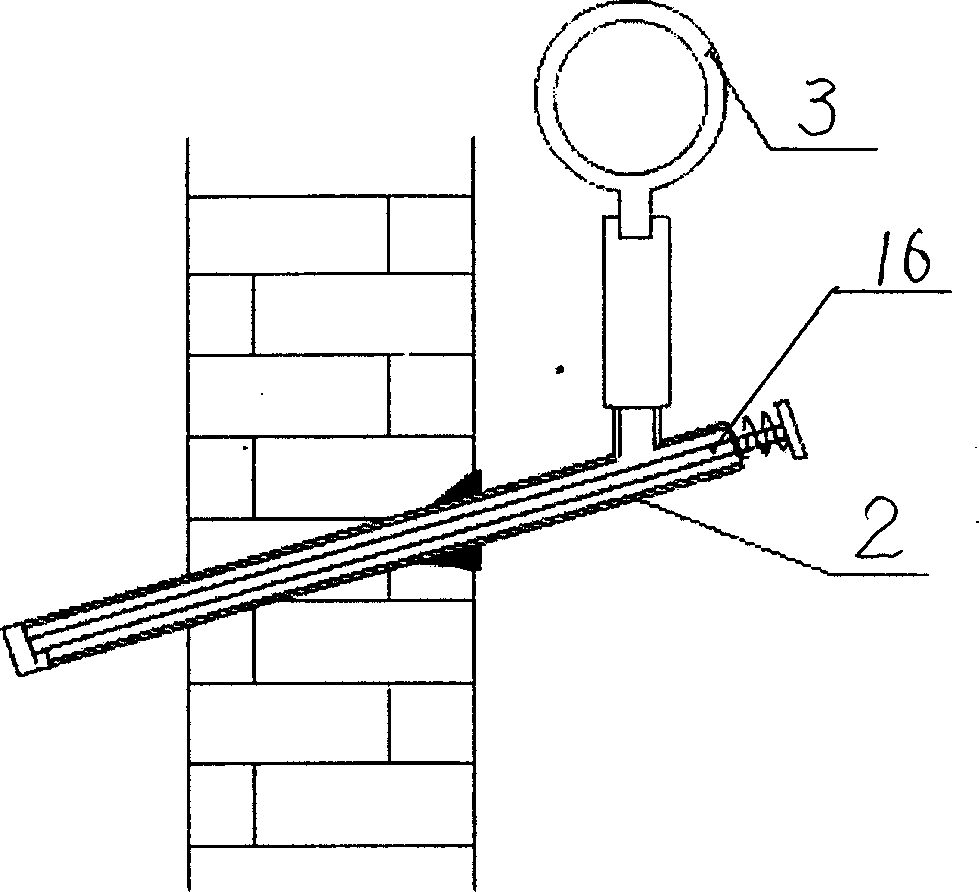

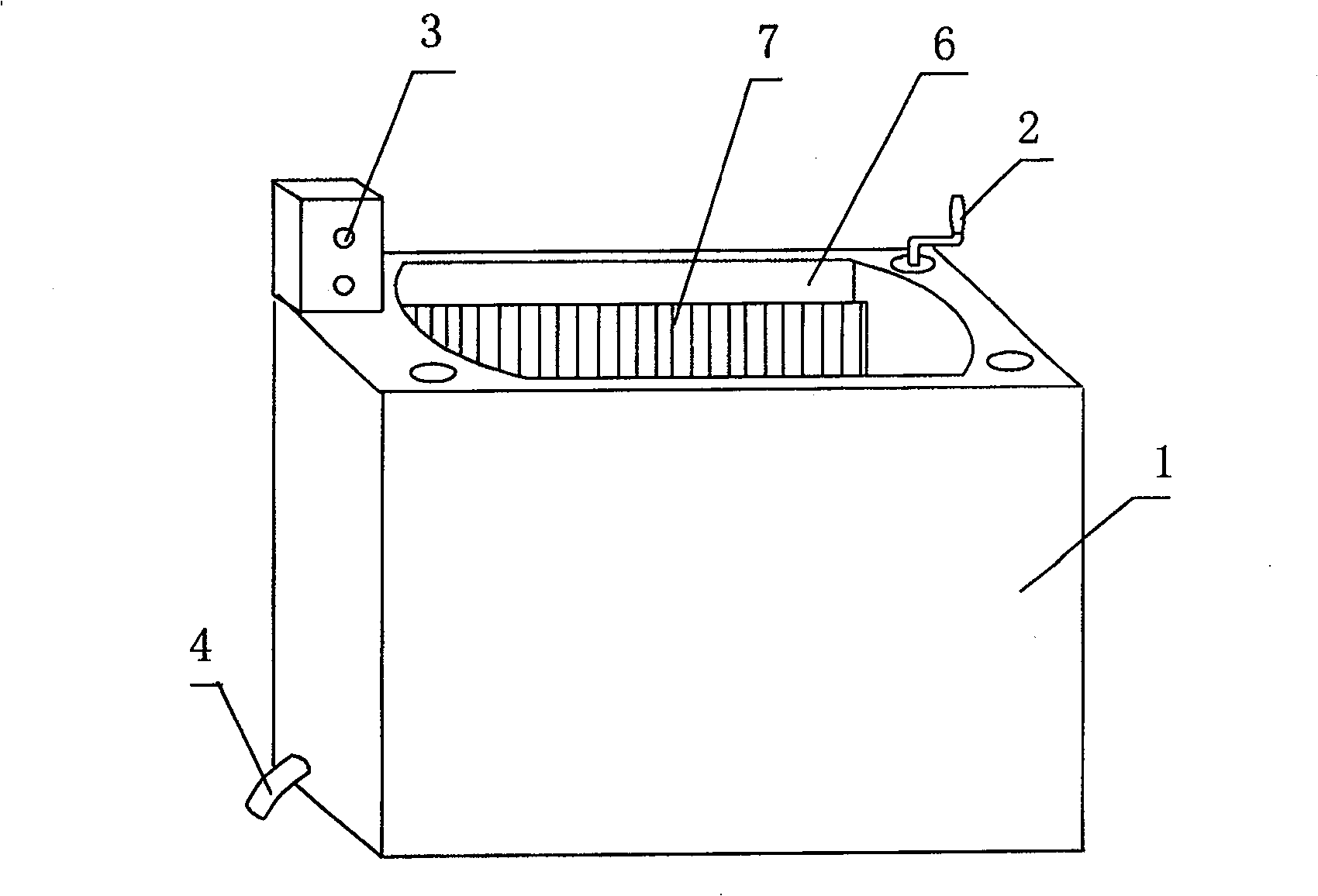

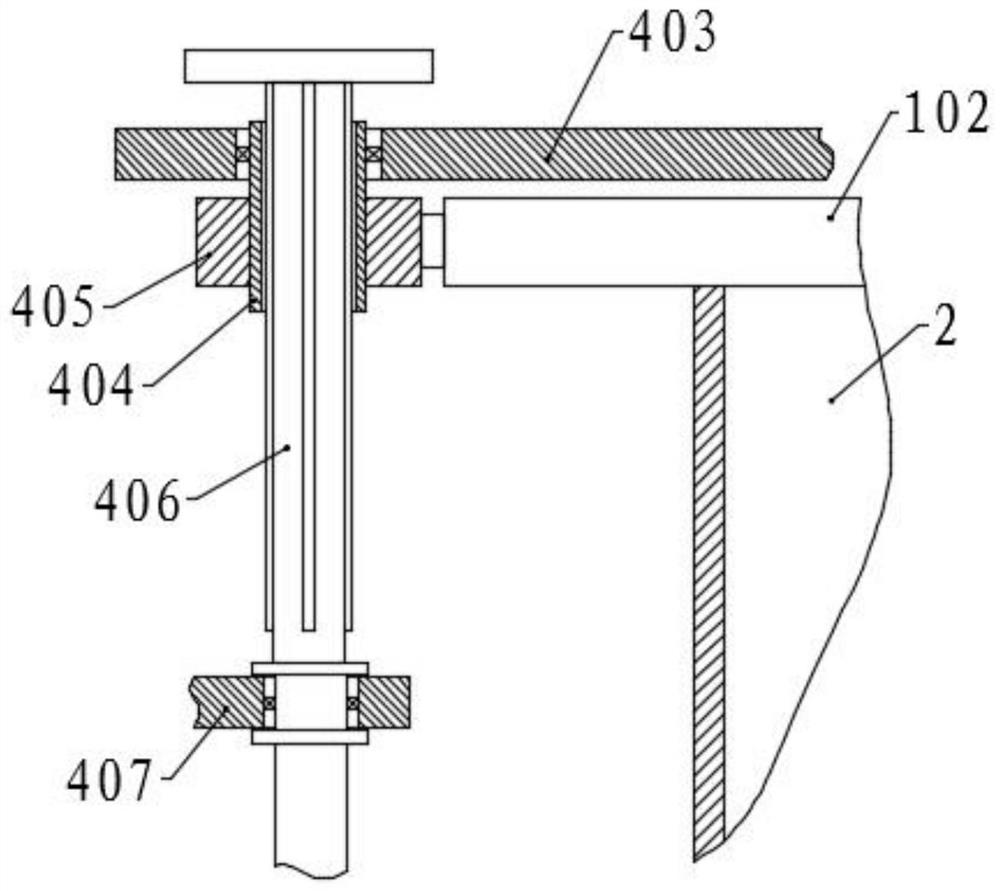

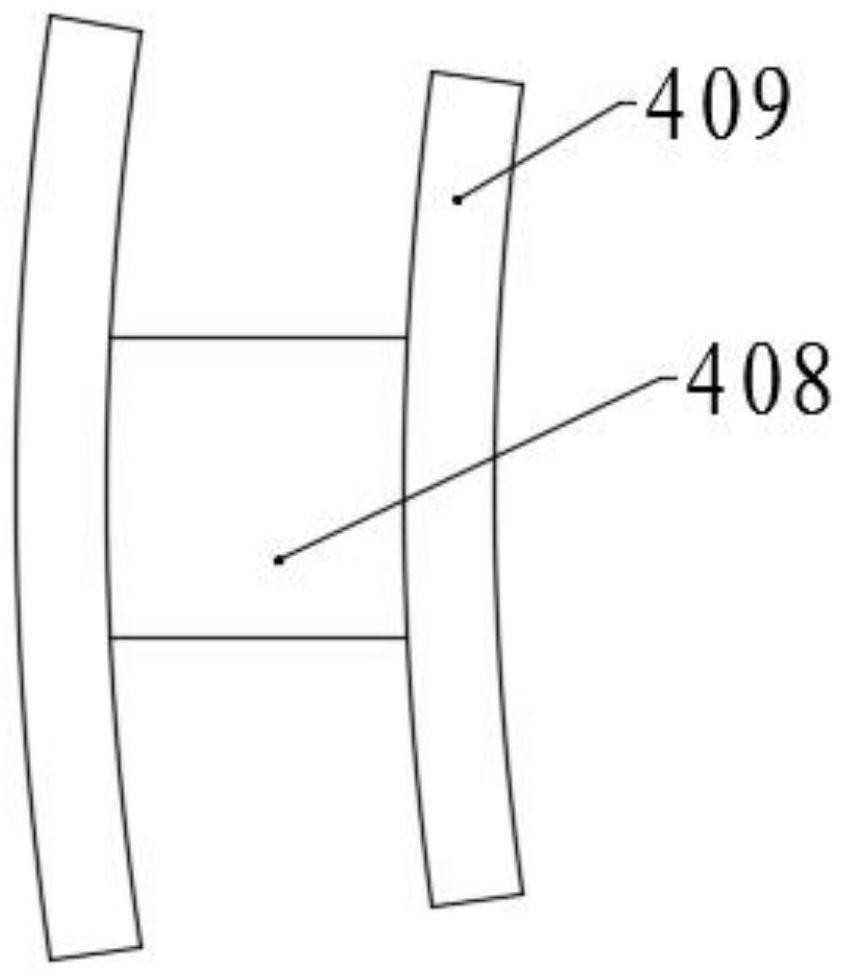

Mechanical kneading method for clothes and kneading type washing machine

InactiveCN100540782CPlay a role in dehydrationReduce consumptionOther washing machinesTextiles and paperElectricityTransverse plane

A method for mechanically rubbing clothes and a rubbing washing machine. In this method, a long and narrow washing chamber is set between two rubbing surfaces with opposite moving directions, and the clothes are put into the washing chamber. The clothes are clamped and rubbed against each other and released periodically to wash the clothes. The device of the present invention is provided with an outer barrel (1), and the outer barrel is provided with a flat cylindrical inner barrel (6) whose cross-sectional transverse inner diameter is greater than the longitudinal inner diameter, and the outer barrel is provided with a belt roller (12) that is connected to the power unit by transmission. Two parallel transverse belt surfaces of the endless belt (7) on the belt roller pass through the inner barrel side wall, and pass through the inner barrel inner cavity against the inner barrel transverse side wall (6a). The invention has the advantages of fast cleaning speed, high cleaning degree, small detergent consumption, simple structure, low manufacturing cost, convenient placement and moving, convenient use, and can also be used under the condition of no electricity.

Owner:罗丹

A potato and taro vegetable cleaning equipment for agricultural product processing

ActiveCN111772211BEasy to cleanPlay a role in dehydrationFood treatmentAgricultural scienceAgricultural engineering

The invention discloses a potato and taro vegetable cleaning device for agricultural product processing in the technical field of agricultural product processing. It comprises a base, a fixed column, a water tank, a fixed table and a cleaning ring groove fixed on the base, and a rotating table is rotatably connected to the fixed table. , the rotating table is connected with a drive assembly and a plurality of connection assemblies, and the bottom of the connection assembly is connected with a placement cylinder. The invention uses the drive assembly and the connection assembly to make the placement cylinder move around the cleaning ring groove and rotate itself, and clean the vegetables through the bristles. The first cleaning tank cleans the vegetables for the first time, and the second cleaning tank performs secondary cleaning to improve the cleaning effect; the ejector rod slides along the outer ring side wall of the cleaning ring groove, and the ejector rod drives the connecting rod and the placement cylinder through the action of the top plate Move upwards, so that the placement cylinder crosses the partition and enters the next area in the cleaning ring tank; the placement cylinder rotates while moving in the dehydration tank, so that the vegetables and the residual water in the net cylinder are quickly thrown out.

Owner:厉航恺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com