Flame-retardant phosphate-containing diol modified polyurethane coating and preparation method thereof

A technology of polyurethane coating and phosphate ester, applied in the direction of polyurea/polyurethane coating, fireproof coating, coating, etc., can solve the problems of reducing the mechanical properties and mechanical properties of polyurethane materials, poor compatibility of polyurethane, and large amount of additives, etc. The effect of thermal decomposition temperature and thermal stability, increasing flame retardancy, and improving char formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

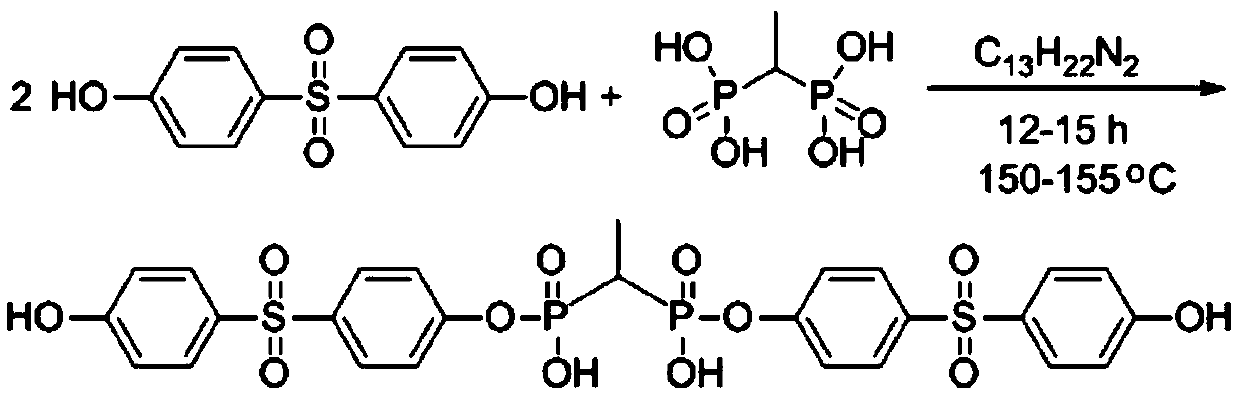

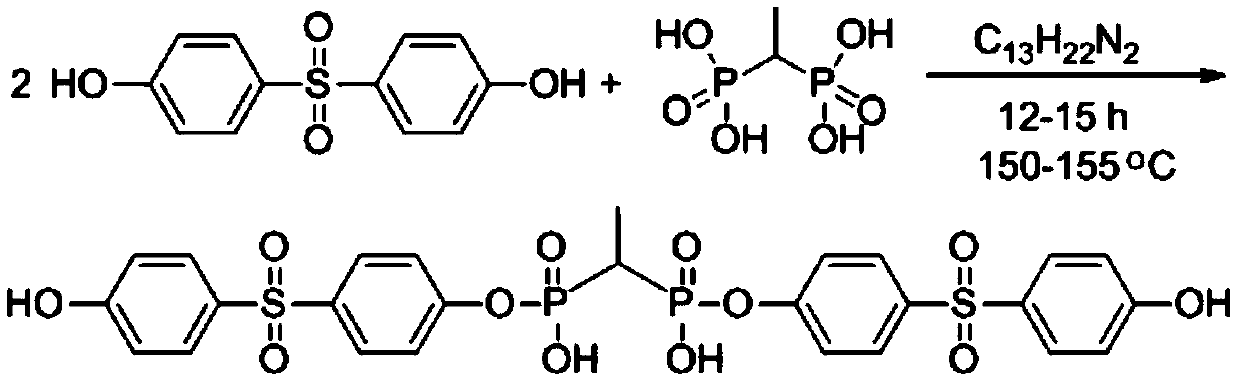

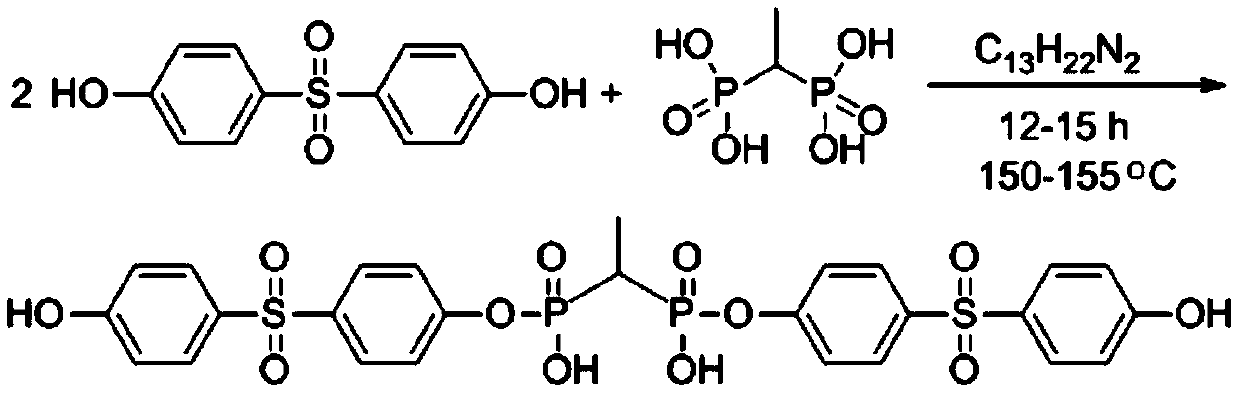

[0026] In order to achieve the above objective, the present invention provides the following technical solution: a flame-retardant phosphate-containing glycol-modified polyurethane coating and its preparation method, including the following raw materials in parts by weight: 6-14 parts 4,4' -Dihydroxydiphenyl sulfone, 3-7 parts of hydroxyethylene diphosphonic acid, 0.2-0.5 parts of esterification catalyst, 45-70 parts of polyoxypropylene glycol, 15-20 parts of 2,4-toluene diisocyanate, 0.8-1.5 parts 1,5-pentanediol, 2-4 parts dihydroxybutyric acid, 0.5-1 parts synergistic catalyst, 2-5 parts neutralizer, 0.5-2 parts chain extender, 4,4'-two The molecular formula of hydroxydiphenyl sulfone is C 12 H 10 O 4 S, its structural formula is The molecular formula of hydroxyethylene diphosphonic acid is C 2 H 8 O 7 P 2 , The structural formula is The esterification catalyst is dicyclohexylcarbodiimide, the molecular formula is C 13 H 22 N 2 , The structural formula is Polyoxypropylene ...

Embodiment 1

[0035] (1) Preparation of bishydroxydiphenylsulfone ethylene bisphosphonate compound: pass N into a 500mL three-necked flask 2 , And add 150mL N-methylpyrrolidone, and then weigh 6 parts of 4,4'-dihydroxydiphenyl sulfone, 3 parts of hydroxyethylene diphosphonic acid and 0.2 parts of dicyclohexylcarbodiimide into three In the neck flask, place the three-necked flask in an oil bath, heat to 150-155°C, stir the reaction at a constant speed for 12-15h, cool to room temperature after the reaction, and concentrate the solution in the three-necked flask on a rotary evaporator under reduced pressure. It is separated by thin-layer chromatography through a silica gel chromatography column. The eluent is petroleum ether: ethyl acetate=2:1. The product is enriched and decompressed by a rotary evaporator and filtered by an oil pump for vacuum distillation to remove the eluent. , The product bishydroxydiphenylsulfone ethylene bisphosphonate compound component 1 is obtained, and the reaction e...

Embodiment 2

[0040] (1) Preparation of bishydroxydiphenylsulfone ethylene bisphosphonate compound: pass N into a 500mL three-necked flask 2 , And add 150mL N-methylpyrrolidone, and then weigh 8 parts of 4,4'-dihydroxydiphenyl sulfone, 4 parts of hydroxyethylene diphosphonic acid and 0.3 parts of dicyclohexylcarbodiimide into three parts. In the neck flask, place the three-necked flask in an oil bath, heat to 150-155°C, stir the reaction at a constant speed for 12-15h, cool to room temperature after the reaction, and concentrate the solution in the three-necked flask on a rotary evaporator under reduced pressure. It is separated by thin-layer chromatography through a silica gel chromatography column. The eluent is petroleum ether: ethyl acetate=2:1. The product is enriched and decompressed by a rotary evaporator and filtered by an oil pump for vacuum distillation to remove the eluent. , The product bishydroxydiphenylsulfone ethylene bisphosphonate compound component 2 is obtained, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com