Dehydration and drying device for scutcher

A technology of dehydration drying and dehydration device, which is used in the treatment of textile material untwisting device, mechanical cleaning, and vibration liquid/gas/vapor removal of textile materials, etc. Production process and other problems, to achieve the effect of not easy to wrinkle and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

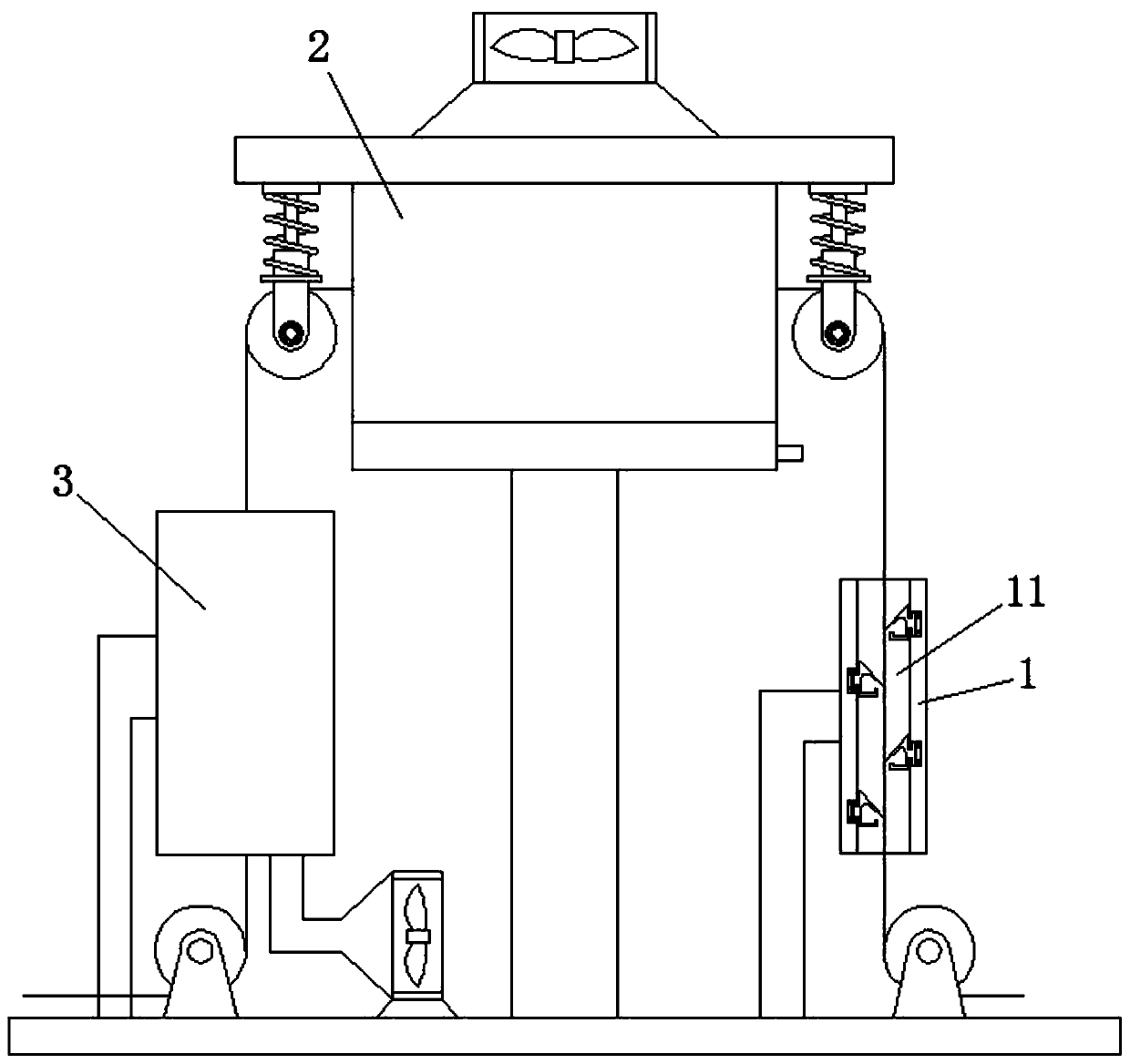

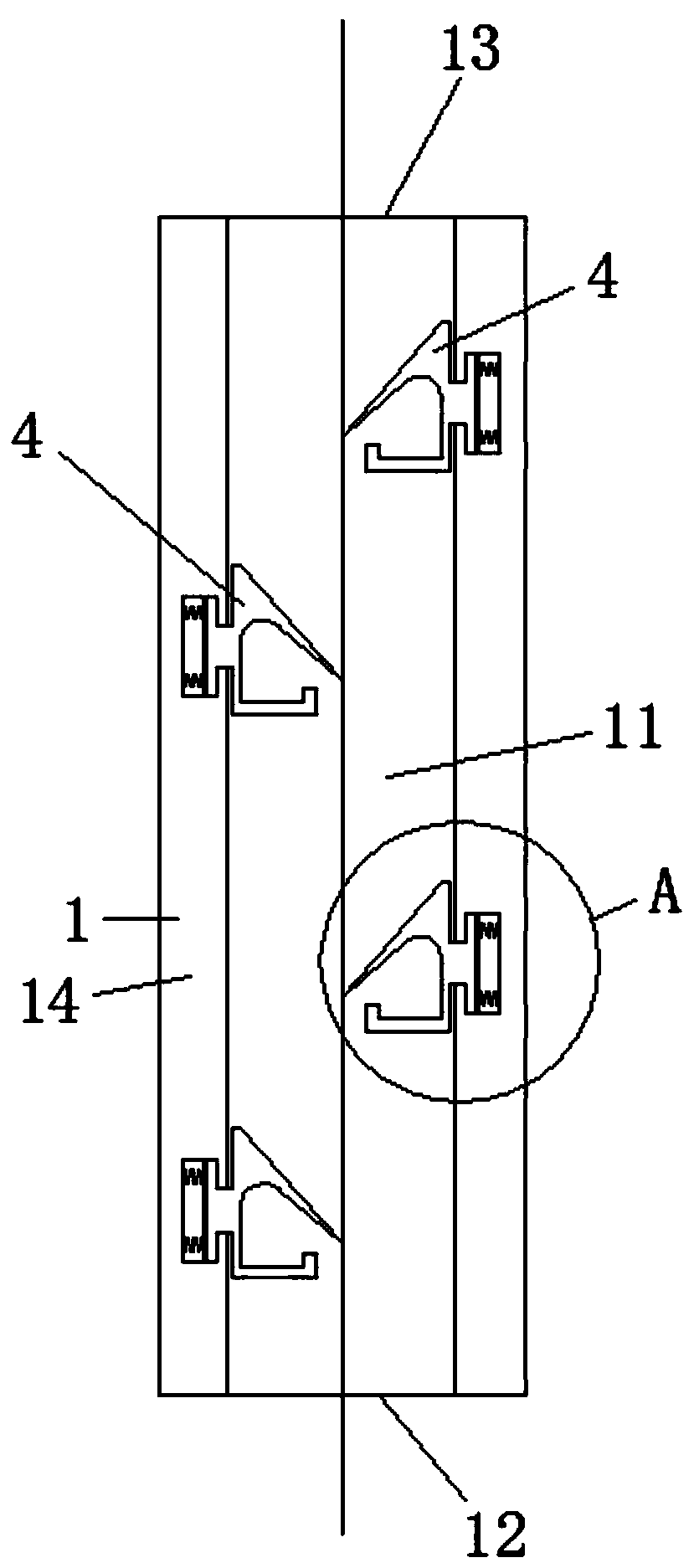

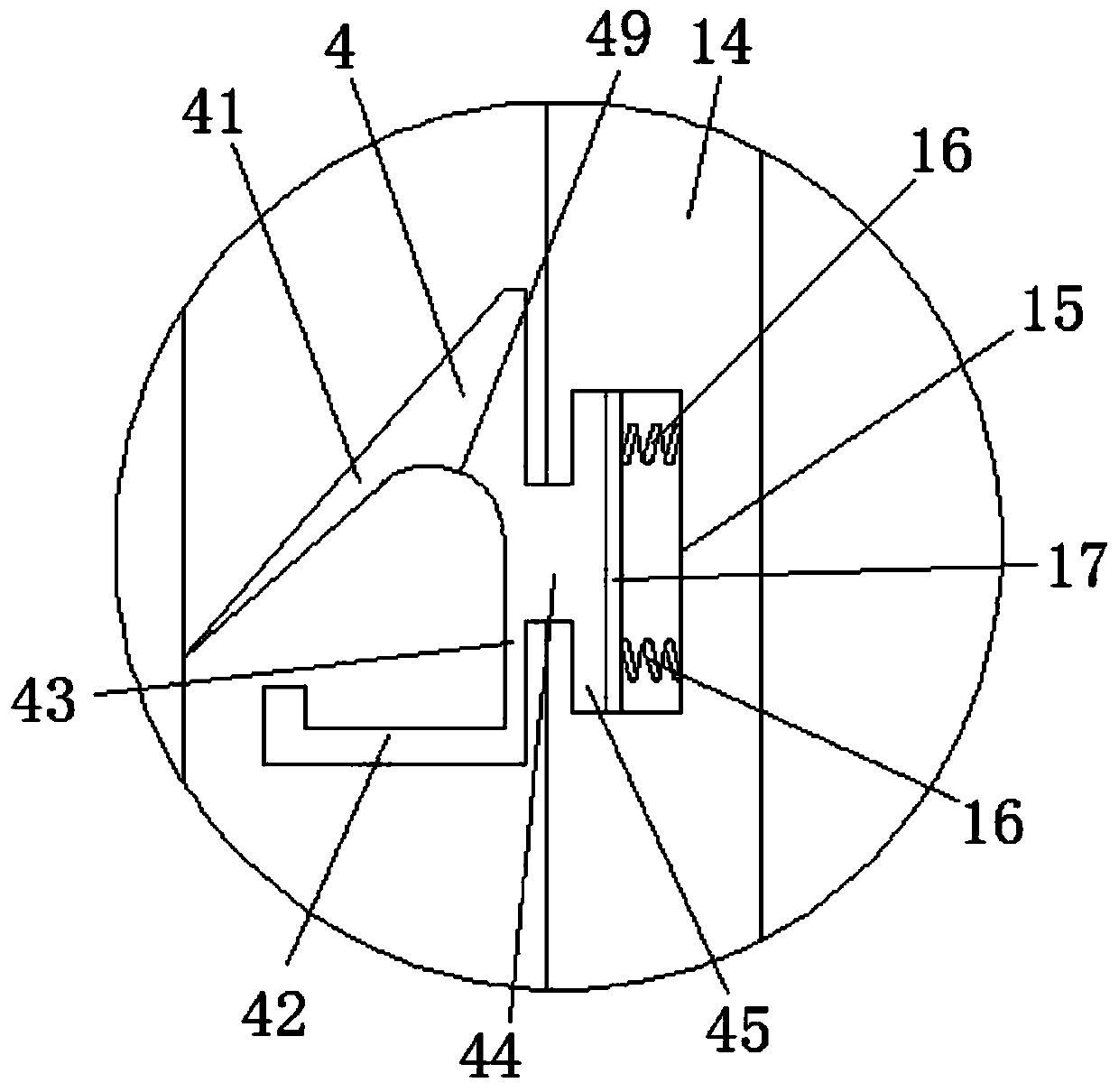

[0025] Such as Figure 1-3 The dehydration and drying device for an open-width machine includes a cleaning device 1 for cleaning the fabric, a dehydration device 2 for dehydrating the fabric, and a drying device 3 for drying the fabric. The cleaning device 1. The dehydration device 2 and the drying device 3 are arranged in sequence. As a preferred solution, the cleaning device 1, the dehydrating device 2 and the drying device 3 are sequentially arranged on the bottom plate 8, and the installation position of the dehydrating device 2 is higher than that of the cleaning device 1 and the drying device 3, and the fabric transmission The device can save horizontal arrangement space.

[0026] The cleaning device 1 is provided with a channel 11 for fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com