Upper reaction support system and construction method for shield-semi-ring origination

A technology of reaction force support and construction method, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem of no adjustment space, etc., and achieve the effect of saving construction period, single process and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

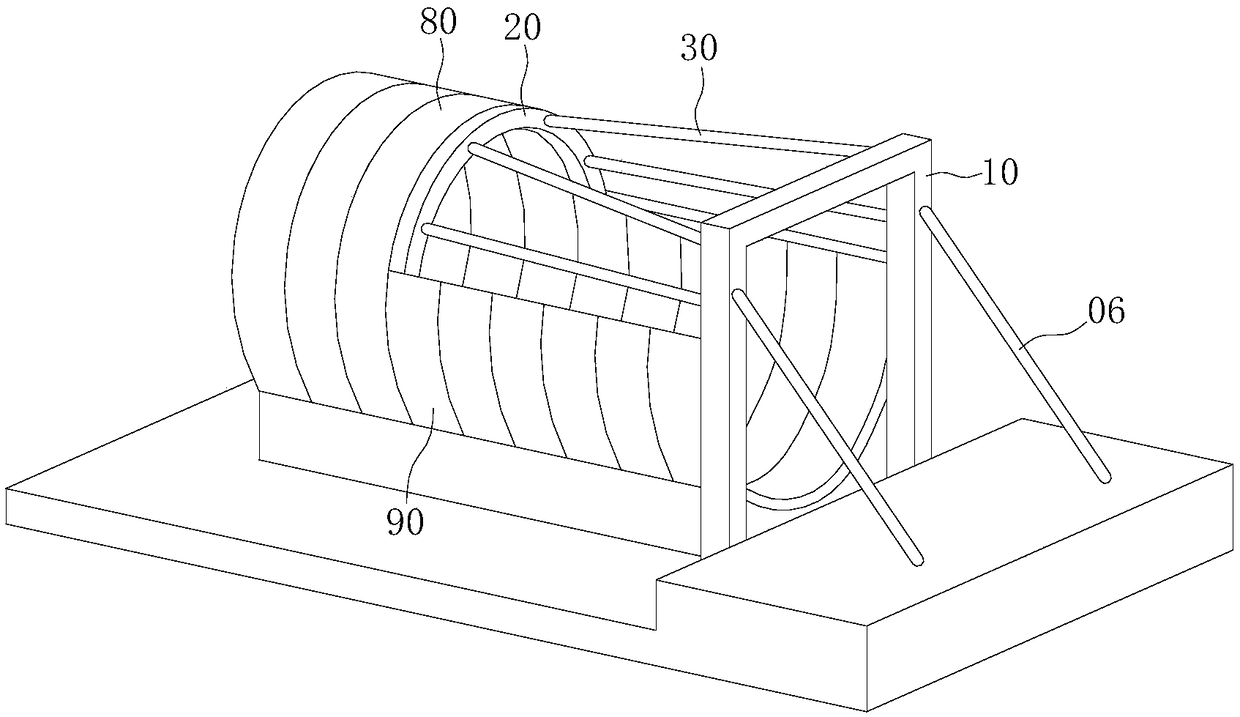

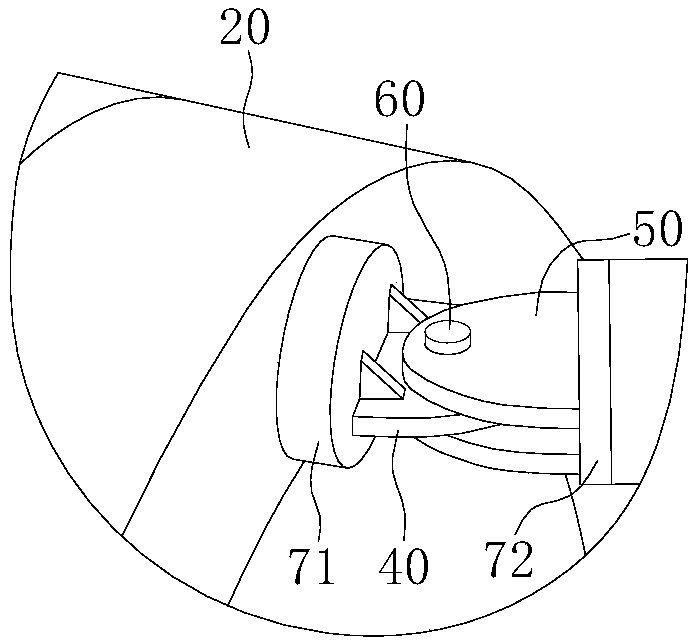

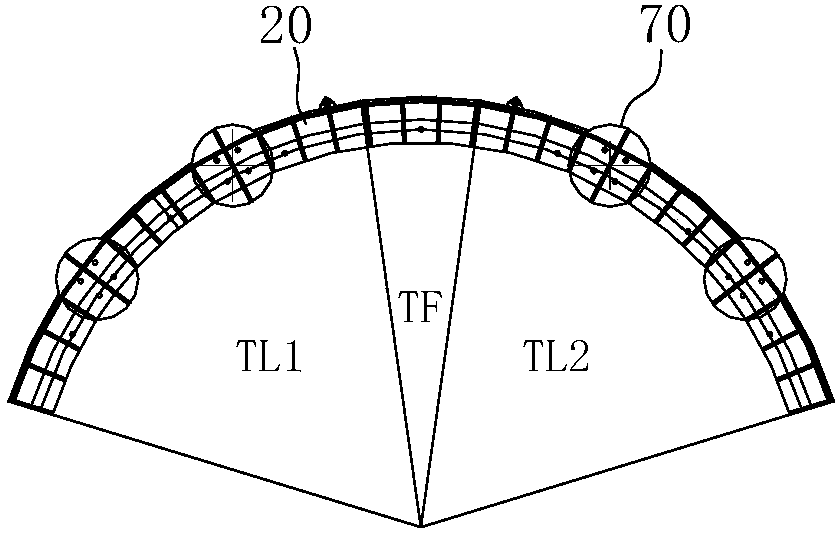

[0030] see Figure 1 to Figure 3 .

[0031] The shield half-ring originating upper reaction force support system of the present invention comprises a reaction force frame 10, and also includes a support plate 20 and a plurality of support rods 30, and the support plate 20 is fixed on the nearest (with the reaction force frame 10 as a reference ) the rear side of the whole ring segment 80, and the support plate 20 corresponds to the shape, size and position of the part beyond the half ring segment 90 of the nearest whole ring segment 80, and one end of each of the support rods 30 is respectively connected to The reaction frame 10 is fixedly connected, and the other end of each support rod 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com