Dual cycle pocked stone pagoda stack gas desulfurizing and dedusting apparatus

A technology for desulfurization, dust removal, and dedusting devices, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, etc., can solve the problems of poor desulfurization effect, small space for fillers and devices, affecting normal use and dedusting effect, etc. To achieve the effect of stable desulfurization and dust removal process, avoiding scaling and clogging, and high desulfurization and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

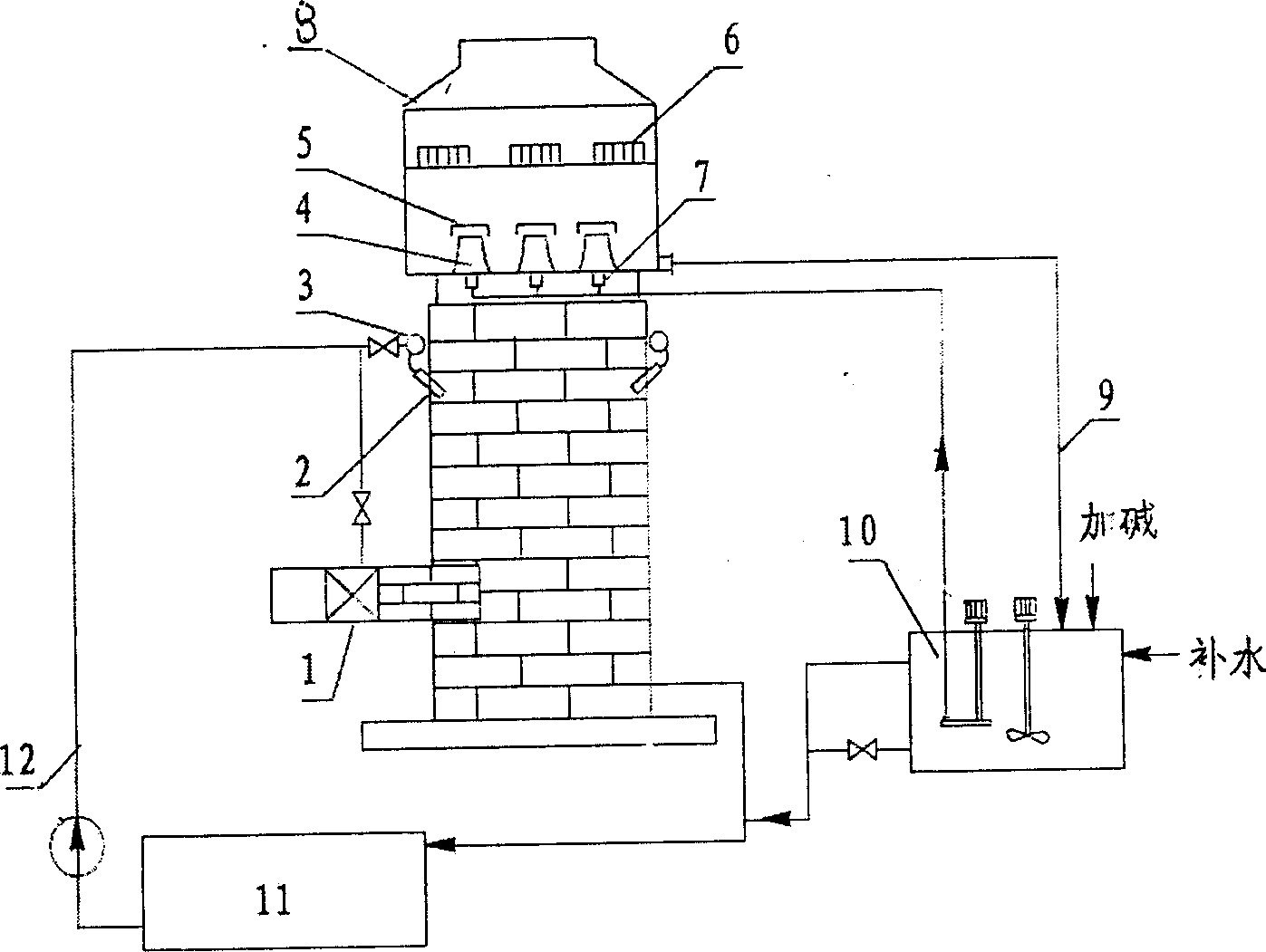

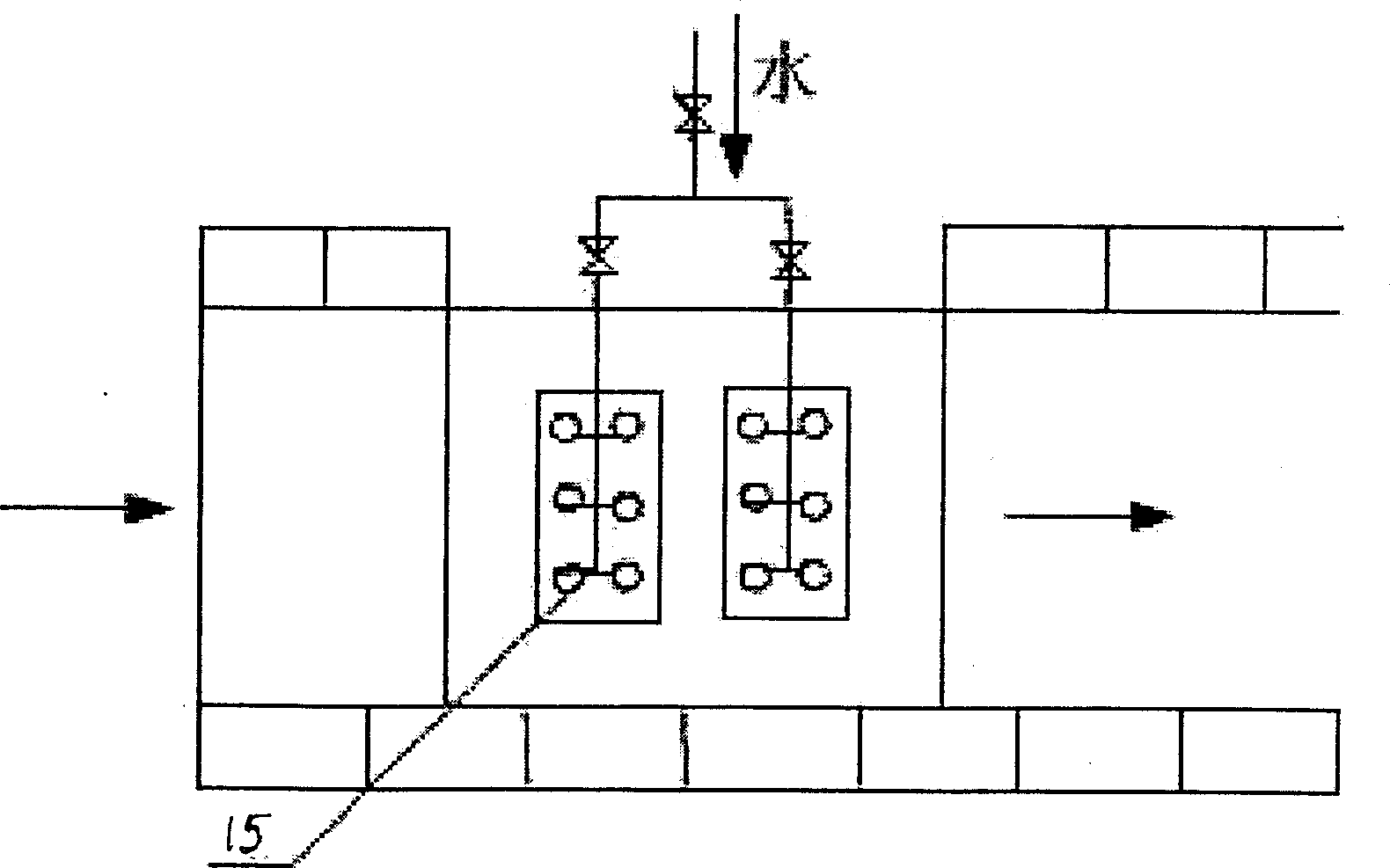

[0012] The flue gas desulfurization and dedusting device of the double-circulation stone tower of the present invention includes: a main body of the stone tower, a liquid distribution device, a gray water circulation system 12 and a settling tank 11 . Among them: such as figure 1 , 2 As shown, an annular humidifying atomizer 1 is installed in the inlet channel near the bottom of the main body of the granite tower. The nozzles 15 of the annular humidifying atomizer are divided into two or more groups, and each group is relatively horizontally installed in the inlet channel The side wall of the nozzle, the water outlet of the nozzle is perpendicular to the direction of the flue gas flow.

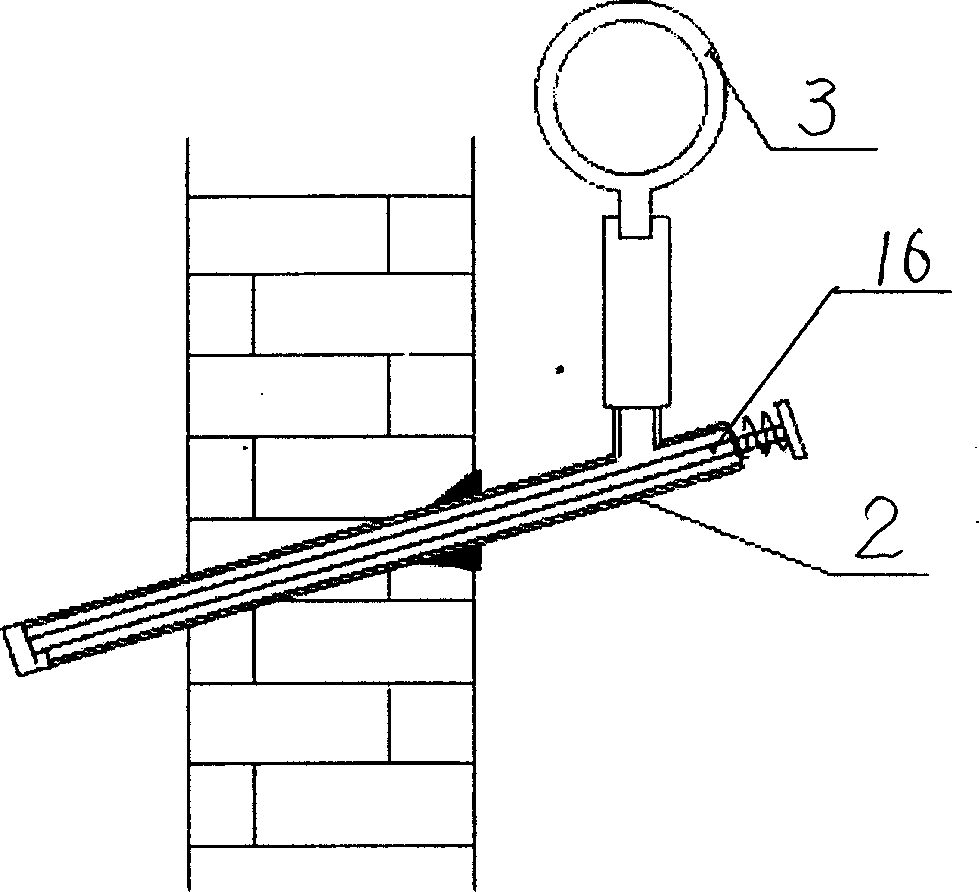

[0013] Such as figure 1 , 3 As shown, the liquid distribution device is a plurality of liquid distribution pipes 2 that are evenly distributed along the circumference near the top of the main body of the stone tower and extend into the tower. Each liquid distribution pipe is sealed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com